FuelCell Energy and Toyota Motor North America Inc. (Toyota) celebrated the grand opening of the first-of-its-kind “Tri-gen” system at the Port of Long Beach, California. Tri-gen uses biogas, also known as renewable natural gas (RNG), to produce renewable electricity, renewable hydrogen, and usable water. It was built to support the vehicle processing and distribution center for Toyota Logistics Services (TLS) at Long Beach, Toyota’s largest North American vehicle processing facility that receives approximately 200,000 new Toyota and Lexus vehicles annually.

“The goal of our collaboration with FuelCell Energy was to find sustainable solutions for the TLS vehicle processing facility here at the Port of Long Beach as part of our goal to remove carbon dioxide [CO2] emissions from our operations,” said Group Vice President of Sustainability and Regulatory Affairs at Toyota, Tom Stricker. “This groundbreaking facility shows that there are ways to reduce our emissions and burden on natural resources with scalable technology based on hydrogen.”

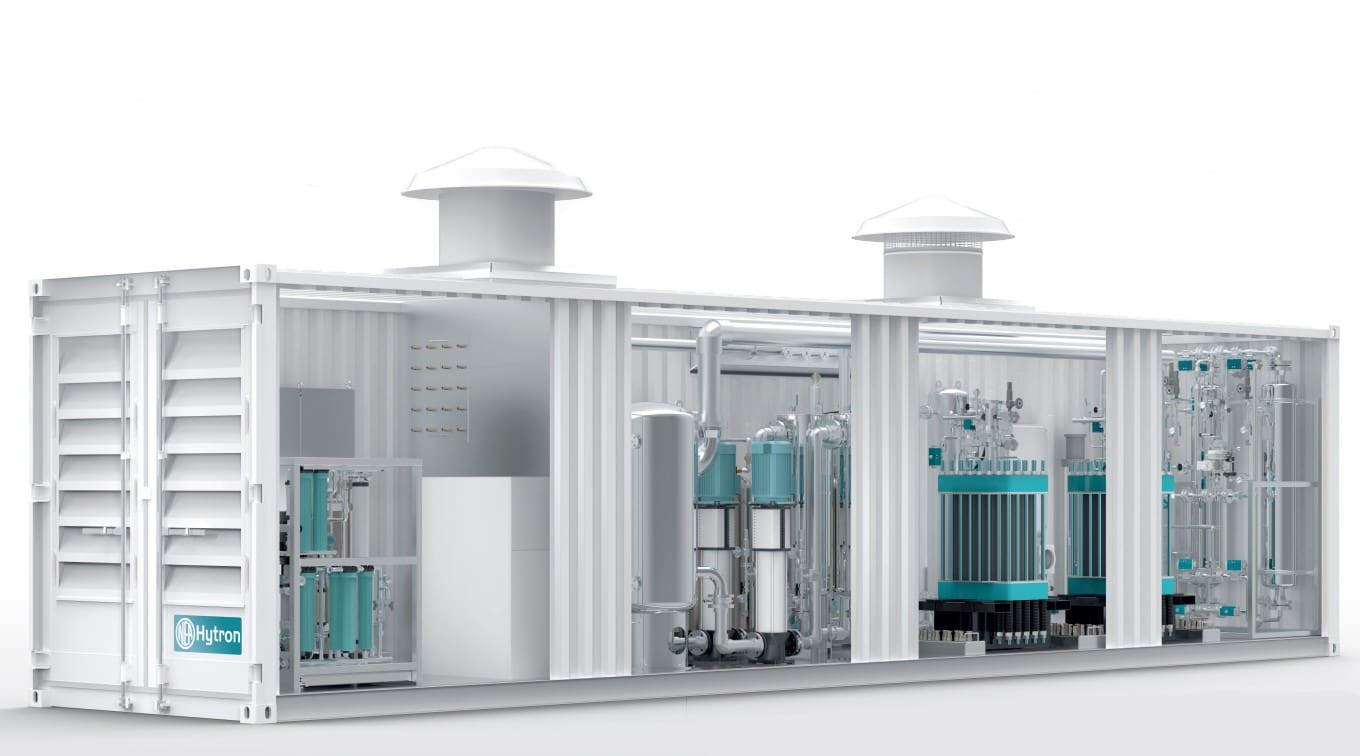

FuelCell Energy’s Tri-gen platform will make TLS Long Beach Toyota’s first port vehicle processing facility powered by 100% on-site generated renewable electricity. FuelCell Energy’s fuel cell technology uses an electrochemical process that converts directed renewable biogas into electricity, hydrogen, and usable water with a combustion-free process that emits virtually no air pollutants.

“Tri-gen demonstrates that hydrogen-based energy can benefit businesses, deliver zero-emissions transportation for light- and heavy-duty vehicles, support improved air quality in local communities, reduce water usage, and deliver immediate and long-term benefits to the environment,” FuelCell Energy Chief Executive Officer (CEO) and President Jason Few said. “As a company, we are living our purpose when we enable visionary customers like Toyota to decarbonize their operations and harness the energy solutions offered by hydrogen — all while leaving communities with cleaner air and easing the strain on power grids and water supplies.”

Tri-gen produces 2.3-MW of renewable electricity, part of which will be used by TLS Long Beach to support its operations at the port. Excess electricity is delivered to the local utility, Southern California Edison, under the California Bioenergy Market Adjustment Tariff (BioMAT) program, adding a renewable, resilient, and affordable baseload electric generation resource to the electric grid.

Tri-gen can also produce up to 1200 kg/day of hydrogen for the fueling needs of Toyota’s incoming light-duty fuel cell electric vehicle (FCEV) Mirai while also supplying hydrogen to the adjacent heavy-duty hydrogen refueling station to support TLS logistics and drayage operations at the port. As of January 1, 2024, California’s Advanced Clean Fleet Regulation will only allow zero-emissions trucks to newly register as drayage trucks. By 2035, all drayage trucks will be required to be zero-emissions. The Tri-gen platform supports FCEV Class 8 trucks today and is there to support ongoing migration to zero emission trucks between now and 2035. Hydrogen production can be ramped up and down based on demand. In January Toyota used the renewable hydrogen produced at Tri-gen to fill the first Toyota Mirai vehicles at TLS, and in April the first heavy-duty FCEV Kenworth T680 Class 8 truck was filled at the adjacent Shell HD filling station using Tri-gen-produced renewable hydrogen.

The water byproduct of hydrogen generation can produce up to 1400 gallons (5300 liters) of usable water per day, which is being repurposed for TLS car wash operations for vehicles that come into port before customer delivery. This helps reduce the demand on the constrained local water supplies by approximately half a million gallons per year.

By supporting TLS operations at the Port of Long Beach, Tri-gen is expected to help reduce more than 9000 tons (8165 tonnes) of CO₂ emissions from the power grid each year. This supports both TLS’ carbon reduction goals as well as the Port of Long Beach’s goals to reduce carbon emissions.

“The dawn of the renewable hydrogen era is upon us, thanks to our collaboration with Toyota and FuelCell Energy and their innovative Tri-gen system,” said Port of Long Beach CEO Mario Cordero. “The green power generated by the Tri-gen system, and similar projects, is part of our multi-layered strategy to fuel our goal to become the world’s first zero-emissions port.”

Tri-gen will also help avoid more than six tons of grid NOx emissions that are harmful to both people and the environment today. Using hydrogen-powered fuel cell Class 8 trucks in port operations has the potential to reduce diesel consumption by more than 420,000 gallons (1.59 million liters) per year.

“FuelCell Energy and Toyota’s collaborative effort signifies technological innovation and also positions Long Beach at the forefront of global leadership in renewable energy solutions,’’ said Long Beach Mayor Rex Richardson. “This transformative initiative solidifies our city’s status as a trailblazer in green initiatives and shows our dedication to a cleaner, more sustainable future for our community and beyond.”