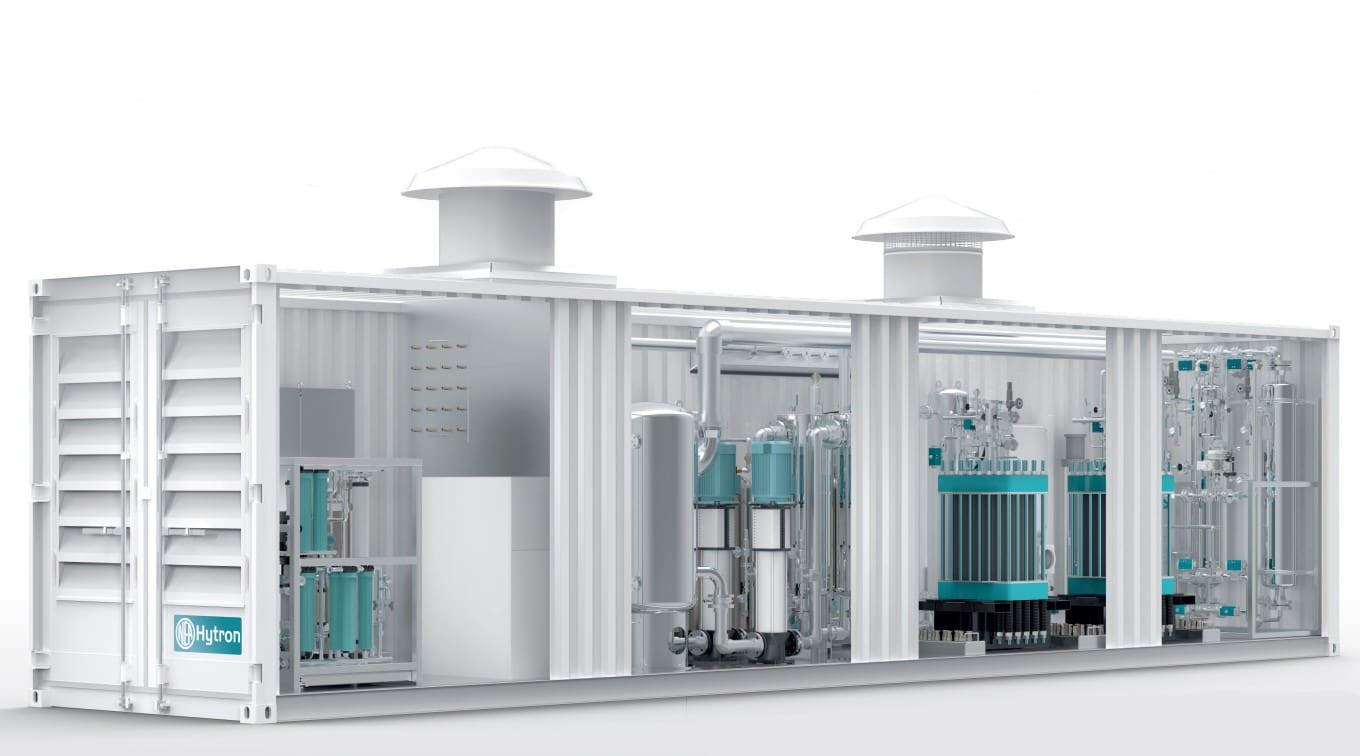

MAN Energy Solutions (MAN) will provide an electric-powered compressor train to HeidelbergCement Norcem for use in the world’s first carbon capture facility for large-scale cement production. The scope of work by MAN Energy Solutions includes the supply of a Type RG 63-7 compressor train with integrated Carbon Capture Heat Recovery (CCWHR) technology, which allows the compression heat of the recovery compressor to be exploited. The steam generators cool the carbon dioxide (CO2) mixture between the compressor stages and generate steam that is in turn used for capture.

When operational in 2024, 400,000 tonnes of CO2 will be captured annually from the Norwegian cement factory in Brevik – corresponding to 50% of the factory’s overall emissions. The carbon will be compressed and liquefied with technologies from cooperation partners, Aker Carbon Capture and MAN, and then transported by ship to an underground storage location.

The cement factory in Brevik will be the first to use the CCWHR technology developed by MAN and Aker Carbon Capture. A new process allows the heat emerging from the compressor system to be recovered and used as steam to meet approximately one third of the total heat demand from the Aker Carbon Capture plant.

“We are delighted to realize the world’s first carbon-capture plant on an industrial scale in a cement-production facility,” said Erik Langholm, executive vice president of projects at Aker Carbon Capture. “Carbon capture and storage plays a big part in cutting European CO2 emissions, and hard-to-abate industries like the cement sector are integral to our ‘10 in 25’ strategy. Aker Carbon Capture has set a target to secure contracts for capturing 10 million tonnes of CO2 annually by 2025.”

“CO2 emissions are currently unavoidable in cement production with the sector accounting for almost 6% to 7% of the world’s carbon-dioxide emissions. This is why the cement industry is key on the road to a decarbonized future,” added Dr. Uwe Lauber, CEO of MAN Energy Solutions. “We are very proud to be able to deliver such an energy-efficient solution for HeidelbergCement Norcem, which is the result of our successful pioneering work in the carbon capture and storage field together with Aker Carbon Capture.”