Smurfit Kappa, a global packaging company, has awarded MAN Energy Solutions (MAN) with the delivery of two TURBAIR vacuum blowers. The vacuum system will be put into operation in the dewatering process of a new Valmet PM5 board machine at the Cerro Gordo paper mill, located in Santa Clara, northeast of Mexico City. The plant specializes in the production of corrugated cardboard for packaging items such as boxes and trays, made from recycled paper and sustainable forestry resources. These packaging solutions are widely used in various sectors, including consumer electronics, industries, medicine, and food.

The energy-intensive process of dewatering plays a critical role in reducing the environmental footprint of paper mills. By cutting consumption of energy and process water in the paper production flow, MAN’s vacuum blower technology supports the paper producer’s efforts to reduce operating expenditures and exceed environmental regulations.

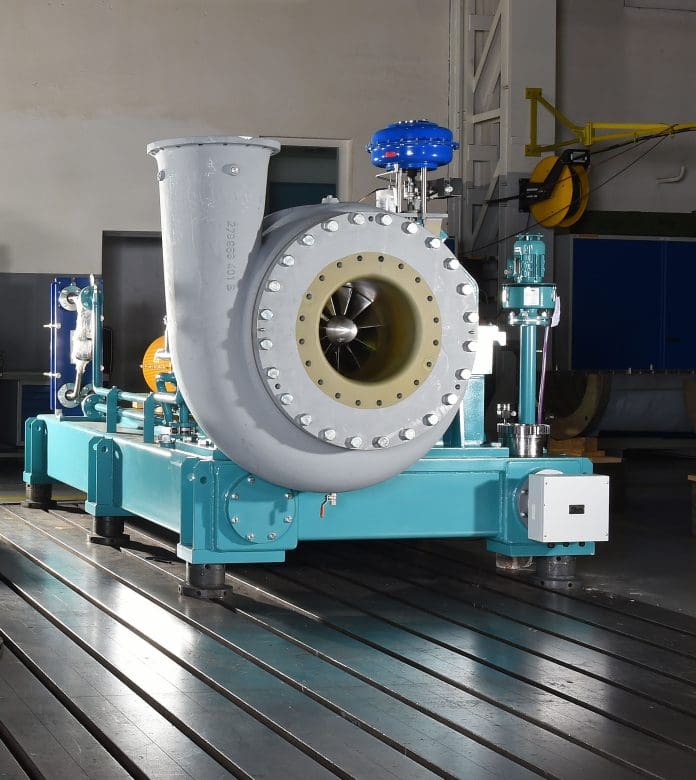

The scope of supply consists of two TURBAIR vacuum systems, engineered and manufactured by MAN Energy Solutions in Zurich, Switzerland. The first, a single-stage RT 71-1 vacuum blower, achieves vacuum levels of up to 48 kPa. It features fully automatic outlet guide vanes, offering flexibility for a broad airflow range while maintaining the required vacuum level. The second, a multistage RC 95-4 vacuum blower, provides four different vacuum levels ranging from 21 to 56 kPa. Both blowers are driven by frequency-controlled electrical drives that ensure additional flexibility and a broad operating range. The delivery is scheduled for autumn 2024.

“Our TURBAIR vacuum blower systems provide an eco-friendly alternative to water ring pumps, enabling board and tissue manufacturers to achieve substantial savings of up to 80% in energy consumption,” said Manfred Dobler, head of sales for paper industry at MAN Energy Solutions. “As a result, our technology solution not only reduces carbon dioxide emissions but also significantly cuts down on paper production costs.”

Smurfit Kappa’s Cerro Gordo board mill is situated approximately 7350 ft. (2240 m) above sea level. The lower atmospheric pressure at this high altitude reduces the maximum vacuum levels attainable. To counteract this loss, the vacuum blower technology deployed needs to achieve high vacuum levels to sustain a consistent vacuum for the dewatering process.

“The plant’s high-altitude position posed a considerable challenge in identifying a vacuum system capable of delivering the required high vacuum levels without compromising on the compactness and small-footprint criteria of the solution”, said Mario Olvera, project manager at Smurfit Kappa. “With the TURBAIR vacuum systems, we have discovered a very efficient technology solution that not only meets our technical demands but also reinforces our strong commitment to operational resilience and sustainable practices.”