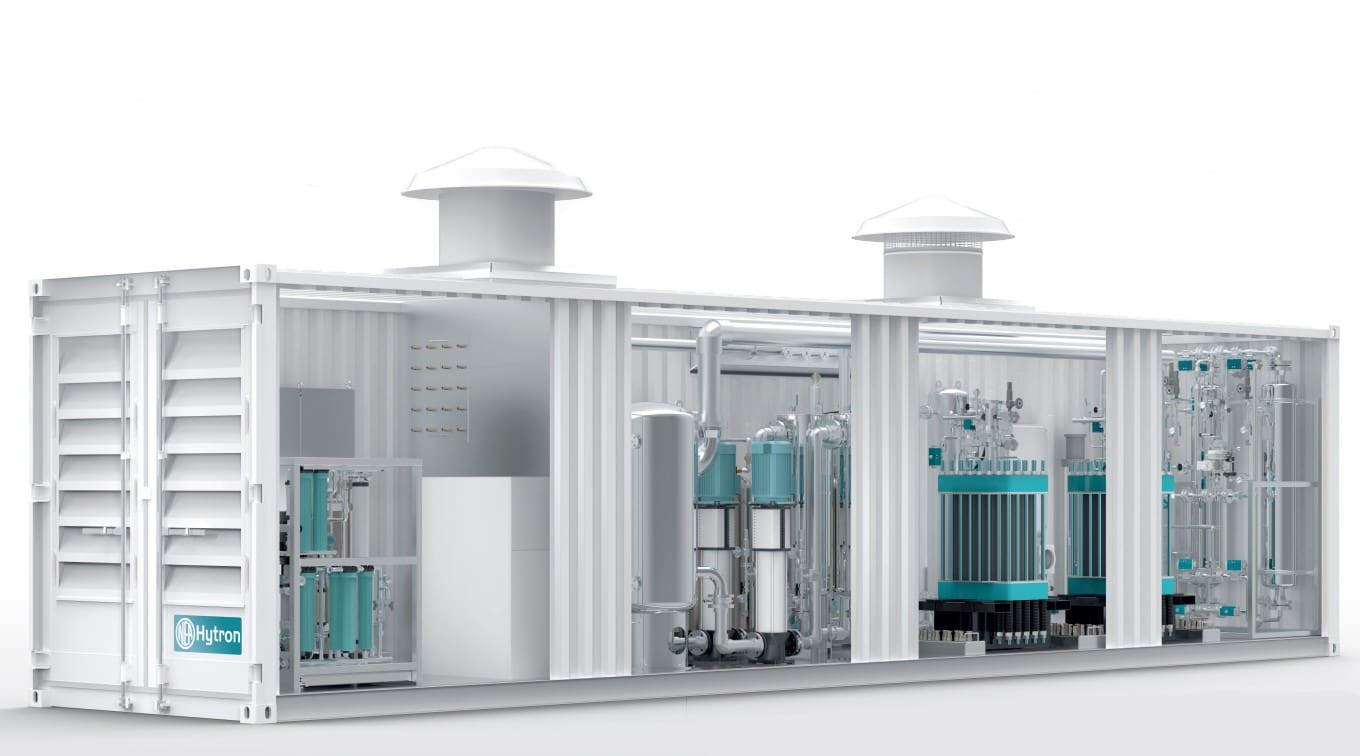

Air Liquide and Siemens Energy officially inaugurated their joint venture gigawatt electrolyzer factory in Berlin. The mass production of electrolyzer components will allow the manufacturing of low-carbon hydrogen at industrial scale and competitive cost. The factory will ramp-up to an annual production capacity of 3 GW by 2025. Once produced, the assembly of the modules can be carried closer to electrolyzer project sites, contributing further to the cost effectiveness of the solution. Located in Berlin, the manufacturing site spans more than 21,528 sq.ft. (2000 m2). It leverages automation and robotics for the series production of proton exchange membrane (PEM) electrolyzer modules, the main component of the electrolyzer. According to Air Liquide, the PEM modules offer a high degree of efficiency and are particularly adapted to an intermittent renewable energy supply.

“There is no energy transition without green molecules. With today’s opening and the start of gigawatt-scale production of electrolyzers, we are launching the next step for the commercialization of this vital technology. Now we need to agree on a viable business model with a balanced risk and reward profile to turn the smallest molecule into a big success story,” said Christian Bruch, president and chief executive officer of Siemens Energy.

The strategic partnership benefits from a portfolio of hydrogen projects combining both Air Liquide and Siemens Energy’s pipelines, targeting large industrial-scale projects worldwide in collaboration with customers. In Europe, a number of low-carbon and renewable hydrogen projects are already under development. In Oberhausen, Germany, the Air Liquide’s Trailblazer 20-MW, large-scale electrolyzer project is reaching completion and aims to accelerate the decarbonization of the Rhine-Ruhr industrial basin. Near Port-Jérôme, France, the Air Liquide Normand’Hy 200-MW electrolyzer project is the largest PEM electrolyzer under construction, avoiding the emissions of 275,578 tons (250,000 tonnes) of carbon dioxide per year. Both groups are working on several other large-scale electrolyzer projects, such as Siemens Energy’s ones in Kassø (Denmark) or FlagshipONE (Sweden), which will provide hydrogen for the synthesis of efuels for shipping.

This partnership will leverage Siemens Energy’s technology and industrial capacity along with Air Liquide’s experience with hydrogen along the whole value-chain and capacity to develop custom-made solutions. Both companies will also continue to dedicate research and development capacities to the co-development of the next generations of electrolyzer technologies.

“The mass production of industrial scale electrolyzers is essential to making competitive renewable hydrogen a reality,” said François Jackow, CEO of Air Liquide Group. “Our joint-venture with Siemens Energy brings the best of our respective expertise together and allows us to offer the most-suited products to the market. This state-of-the art technology will soon be operated at the Trailblazer electrolyzer in Oberhausen, with a major scale upcoming for the Normand’Hy electrolyzer project. More than ever, hydrogen is proving to be a key element of the transition to a low-carbon society.”