The Port of Rotterdam CO2 Transport Hub and Offshore Storage project (Prothos) received final investment decision in October 2023, clearing the path for the first large-scale carbon capture and storage (CCS) project in the Netherlands to begin construction.

Lead by the Port of Rotterdam Authority, Energie Beheer Nederland B.V., and N.V. Nederlandse Gasunie, Porthos will store 2.5 MTPA of carbon dioxide (CO2) in exhausted natural-gas reservoirs under the North Sea. Construction of the Porthos infrastructure will start in January 2024. The system is expected to be operational from 2026.

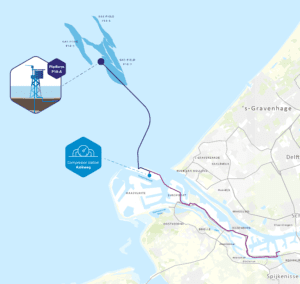

What makes Porthos unique from other CCS projects is that the CO2 will be sourced from various companies in the Rotterdam port area — a region accounting for more than 16% of Dutch CO2 emissions. Porthos has signed agreements with Air Liquide, Air Products, ExxonMobil, and Shell. These companies will invest in their own capture installations to supply CO2 to Porthos. Porthos will feed the CO2 into a common pipeline that will run 18.6 miles (30 km) through the port of Rotterdam to depleted gas fields offshore where it will be permanently stored at a depth of 1.8 to 2.4 miles (3 to 4 km) under the seabed.

Onshore

The collective pipeline running through the Rotterdam port extends from the eastern end of Oude Maas in the Botlek area, through the Europoort area to the compressor station at Maasvlakte. The collected CO2 will flow in a gaseous state at a pressure of 507 psi (35 bar) through the pipeline, which has a diameter of approximately 42 in. (108 cm).

Planned Compression

MAN Energy Solutions will provide three integrally-geared RG 28-6 type compressor trains to the project with an order for two additional units at a later stage. The compressor trains will be located at a station on Maasvlakte, the western extension to Europort. There, the CO2 will be compressed to different discharge pressure levels with each compressor handling up to 250 tons (227 tonnes) of CO2 per hour.

Offshore

From the compressor station, a 13.6-mile (22-km) pipeline will transport the CO2 in gaseous form at a maximum pressure of 1885 psi (130 bar) offshore to the P18-A platform in the North Sea. There, the CO2 will be pumped into the exhausted P18 gas fields at a depth of 10,498 to 11,482 ft. (3200 to 3500 m) below the seafloor, which have a CO2 storage capacity of around 37 million tons (33.6 million tonnes).

The former gas platform P18-A will be reused for the storage of CO2. The platform will be fitted with the facilities required to transport the collected CO2 to the injection wells.

The collected CO2 will be stored in the pores of the sandstone substratum, which once contained natural gas that was hermetically trapped under high pressure between a nonpermeable layer of caprock and sealing plane faults. Once CO2 injection has been completed — when the reservoir is full and at the correct final pressure — the wells will be sealed.

“We are extremely proud to be part of this pioneering project aimed at reducing CO2 emissions. Not only will Porthos play a vital role in propelling the Netherlands toward achieving net-zero emissions, but the project is also innovative in its approach that aims at establishing a CO2 transport and storage infrastructure serving multiple companies,” said Dr. Uwe Lauber, chief executive officer of MAN Energy Solutions. “Such game-changing initiatives are crucial in advancing CCS efforts and effectively reducing hard-to-abate emissions.”