Elliott Group (Elliott) has introduced an impulse-type, two-phase cryogenic expander that allows for the expansion of liquefied gases into two-phase mixtures. According to Elliott, harnessing the energy of two-phase expansion increases the expander’s generator output, reduces boil-off losses, and improves the overall liquefaction and cooling processes.

“We are offering these expanders to improve process efficiency and reduce boil off gases during liquefaction, refinery, and cooling processes of natural gas,” said Enver Karakas, senior engineer at Elliott. “It’s a new technology but most of the design features are based on Elliott’s existing cryogenic liquid expanders and axial flow impulse turbines. Elliott has been manufacturing cryogenic expanders since 1998. This is the development of a new product based on the extremes we have encountered and the 15+ years of experience we have.”

Hydraulic components are from Elliott’s existing axial flow impulse turbines. Nozzle vane and rotor assembly blades are constructed using propriety materials developed by Elliott to withstand cavitation erosion due to vaporization.

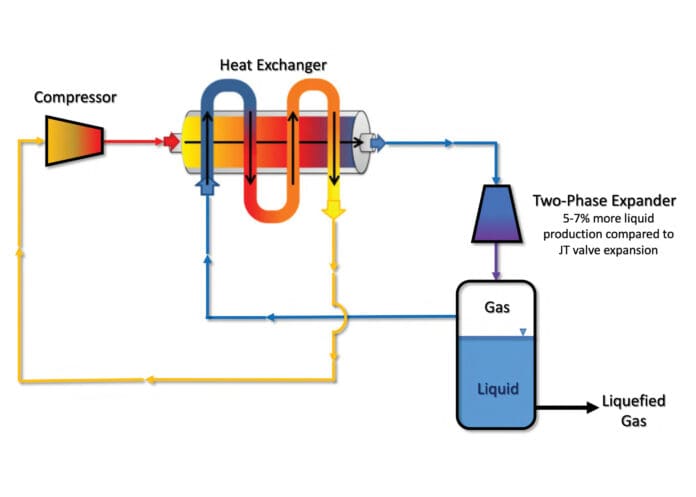

Each custom-designed expander replaces expansion valves, commonly known as Joule Thomson (JT) valves, in cooling/refrigeration processes. “JT valves are mainly used to reduce process fluid’s pressure to a desired level,” said Karakas. “JT valve expansion is an isentropic expansion, where there is no energy recovery, or enthalpy change. With Elliott’s new cryogenic expander, process fluid’s kinetic energy is converted to electrical energy via the expander’s hydraulic components and the generator. This results in electric generation but more importantly enhances cooling of the cryogenic fluid. The final outcome is less vapor generation and more liquid at the discharge line. It’s not only the energy recovery that we are gaining here, we are also gaining product. Thermodynamic analysis shows that this corresponds to 5% to 7% more liquid at the discharge compared to an expansion via JT valve.”

Karakas continued, “At a liquefaction process, fluid is often cyclically cooled to maintain or achieve liquid phase. This is historically done by refrigeration cycle. Refrigeration cycle uses JT valves to reduce the pressure of the fluid,” said Karakas. “During the pressure reduction [expansion], temperature of the fluid decreases. If energy can be extracted during this expansion process, fluid temperature must reduce even more. By implementing this new cryogenic expander to the refrigeration cycle in lieu of a JT valve, energy is extracted from the fluid, resulting in better cooling. The reduction in temperature will increase the amount of liquid phase in the two-phase mixture as additional cooling will allow condensation of the vapor content.”

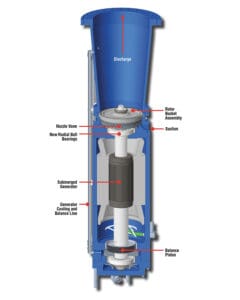

The cryogenic expander has optimized staging for high-efficient operation with vapor mass content up to 35%. In addition, optimized staging minimizes axial load at the radial ball bearings. “The shaft rotor assembly is supported by two new ball bearings. These ball bearings are designed to handle certain amounts of axial thrust due to hydraulic components,” said Karakas. “In addition, a balance piston is used to minimize the axial thrust load. Ball bearings are process fluid lubricated. Balance lines and orifices are used in expander casings to regulate the pressure at the generator cavity to ensure the liquid phase is maintained at this location.”

The new cryogenic expander features an axial flow impulse design with reduced overhung and stage reaction, a vertically suspended upward flow configuration, a single-shaft compact design with submerged generator, and cooling and balance lines to adjust pressure and flow to efficiently cool the submerged generator and lubricate the ball bearings. In addition, it can be retrofitted to existing liquefied natural gas (LNG) liquefaction and cooling applications.

“The generator is sleeved on to the expander shaft directly and submerged into cryogenic process fluid for better cooling,” said Karakas. “The main idea is to eliminate the need for a mechanical seal. Mechanical seals are not very reliable under a harsh cryogenic environment. To improve the reliability and availability of the expander, the mechanical seal is eliminated by the submerged generator design feature.”

According to Karakas, the isentropic efficiency of these units is estimated to be at around 60% to 70%, depending on the mass flow rate and unit pressure drop. “They have generator nameplate ratings ranging from 300 kW to 2.2 MW for a single unit,” said Karakas. “If the process requires high-flow output, these units can be installed and operated in parallel configuration.”

Material testing under cavitation was conducted to determine materials of construction for hydraulic components. “Elliott has been working with major oil and gas companies to implement this new expander technology to an existing LNG refinery and liquefaction terminal,” said Karakas. “One of the biggest challenges we often face as an equipment supplier is the acceptance and approval phase of new technologies by contractors and end users. It is a long process to get an approval from end users to install and operate a new machine or technology. There is a concern when a change is done because it can open a door for a failure. To prevent this, Elliott conducts highly complicated computer simulations and verifies the concept and design via testing in house.”

“This new technology not only increases LNG production, but also recovers energy. Recovered energy can be used to operate any machinery within the plant, which further increases the plant’s efficiency. They can take the recovered energy and use it to run a compressor, for example, or they can put it into grid. This is also a positive impact to emissions in terms of reduction of greenhouse gases to the atmosphere.”