Atlas Copco Gas and Process (Atlas Copco) will supply carbon dioxide (CO2) compression equipment to a renewable biofuels plant project in Europe. The equipment will be used in an 820,000-tons-a-year biofuels facility, located at the Shell Energy and Chemicals Park Rotterdam, the Netherlands (formerly known as the Pernis refinery).

Once completed, the facility will be among Europe’s largest for the production of sustainable aviation fuel (SAF), renewable diesel, and renewable naptha made from biowaste. A facility of this size could produce enough renewable diesel to avoid 2,800,000 tons of CO2 emissions per year, the company said.

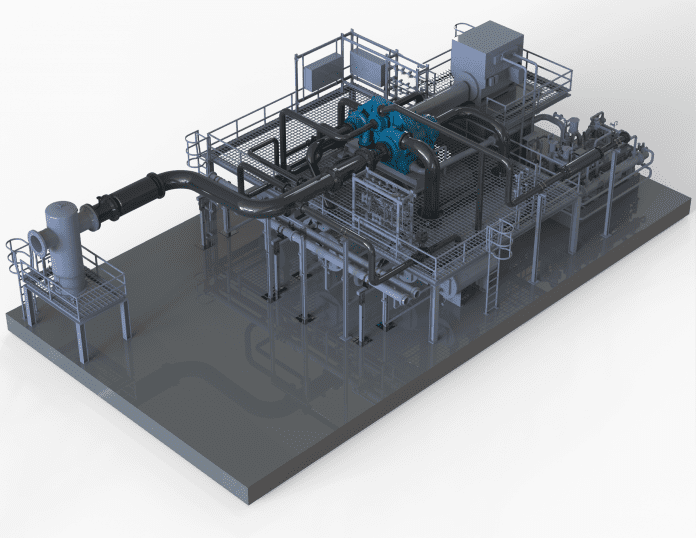

A byproduct from different plant processes, the CO2 will be compressed to a pressure of 42.5 bar by the Atlas Copco 5-stage turbo compressor. The machine is designed to compress 43.5 t/h.

Shell plans to use carbon capture technology at the facility and store the CO2 in an empty gas field beneath the proposed Porthos project in the North Sea.

Expected to start production in 2024, the new facility will help both the Netherlands and the rest of Europe in meeting internationally binding emissions reductions targets. It will produce low-carbon fuels such as renewable diesel from waste in the form of used cooking oil, waste animal fat, and other industrial and agricultural residual products, using advanced technology developed by Shell.

The new facility is expected to contribute to Shell’s aims to become a net-zero emissions energy business by 2050 and achieve the climate goals of the Paris Agreement.