Aker Solutions has been awarded an engineering, procurement, and construction (EPC) contract from Equinor to provide a subsea gas compression system for the Midgard and Mikkel gas reservoirs in the Åsgard field along the Norwegian Continental Shelf (NCS). Successful delivery will mark Aker Solutions’ fifth subsea gas compression module and is a copy of its previously awarded fourth module. Part of this module will be built using existing equipment. Aker describes the deal as a “sizeable contract,” which is defined as between US$22.3 million and US$77.9 million. The contract was booked as order intake in the fourth quarter of 2021 in Aker Solutions’ subsea segment.

Aker Solutions has received a steady stream of EPC work for subsea gas compression systems throughout 2021. Its second delivery came earlier this year when Aker Solutions provided Chevron Australia an all-electric subsea gas compression system that included a complete compression station with three compressor modules and two subsea pump modules, all-electric control systems and actuators, structures including mud mats, a high-voltage electrical power distribution system, several spare modules and requirement, and various associated tooling.

The Åsgard module will be installed at Equinor’s actively operating fields but isn’t expected to interrupt production. Engineering will take place mostly out of Aker Solutions’ Fornebu, Norway, office and fabrication will be done from its Egersund, Norway, yard. Aker Solutions will start on the job immediately and expects it to be delivered in August 2024. “We are pleased to be awarded another important contract by Equinor at the Åsgard field,” said Kjetel Digre, CEO of Aker Solutions. “This award continues to demonstrate the value of our subsea gas compression technology and is closely aligned with our strategy to deliver solutions that help the industry drive toward more sustainable energy production, with lower environmental footprint versus traditional solutions.”

Åsgard Gets An Upgrade

The Åsgard field is one of Equinor’s largest developments on the NCS. Located in the Norwegian Sea about 124 miles (200 km) off the coast of Norway in water depths of around 787 to 1017 ft. (240 to 310 m), the gas from the Åsgard field is pumped via pipeline to Equinor’s Kårstø processing plant and onward to continental Europe. According to Equinor, the field supplies about 388.5 Bscf (11 × 109 m3) of gas annually to European customers.

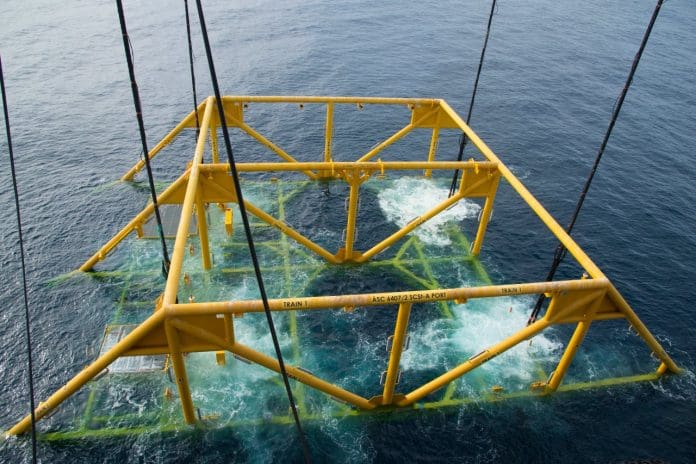

The world’s first subsea gas compression system was delivered by Aker Solutions to Equinor’s Åsgard field in 2015. The technology had been developed through several years of collaboration with the customer and suppliers such as MAN Energy Solutions and ABB. The technology has since been taken further. Chevron Australia’s previously mentioned Jansz-lo Compression Project will have close to three times more compression power than the existing Åsgard system at comparable physical dimensions and lower weights. The existing two-train Åsgard compression system has been running successfully for nearly seven years with uptime close to 100%.

Aker Solutions has been working closely with Equinor to try and find ways to extend profitable field operations. In the meantime, the existing compression modules are being refurbished and upgraded to accommodate a higher compression ratio. This refurbishment, along with the installation of a new subsea gas compression module, is expected to extend the field’s lifetime as reservoir pressure naturally declines. The existing wet gas system is designed for continuous liquid injection in the compression module. “The continued Åsgard development demonstrates how we can help further enhance recovery rates at existing fields, while maintaining and reusing existing infrastructure and subsea equipment,” said Maria Peralta, executive vice president and head of Aker Solutions’ subsea business. “It also demonstrates the value of Aker Solutions’ modular compression system which is scalable and flexible to support enhanced production at declining reservoir pressures. We look forward to continuing our relationship with Equinor and maintaining our strong focus on safe and efficient operations, with lower environmental footprint.”

Equinor’s Need For Subsea Compression

Decades of drilling the North Sea gives Equinor an expansive playing field right in its backyard. In just the first three quarters of 2021, Equinor generated more free cash flow (FCF) than any previous year in company history. Low cost of production means Equinor can breakeven at lower oil and gas prices than many of its competitors, which is the main reason it’s able to generate such high FCF. Aside from selectively investing in other plays around the world, Equinor has limited oil and gas investment options. Therefore, it’s no surprise that Equinor’s capital expenditures (capex) are down more than 25% compared to three years ago.

To avoid a gradual decline in its business, Equinor has made two major strategic moves. The first is to invest in projects like the Åsgard field to make its existing assets profitable for longer. Equinor believes that the new projects it brings online in 2030 will have an average breakeven below US$35 per barrel Brent, but it also expects oil and gas production to be the same in 2030 as it was in 2020. In this vein, Equinor is focused on greater efficiency, not necessarily greater output, from the NCS. Beefing up the efficiency of the Åsgard field subsea compression system is a textbook example of the ways that Equinor can achieve low spending and strong long-term profitability from mature fields.

Equinor’s second big strategic move is a shift toward alternative energy. Equinor has pledged to reduce emissions by 20% by 2030, 40% by 2035, and be carbon neutral by 2050. In 2021, it pledged to allocate 12% of its growth capex to low-carbon investments. By 2030, it expects to be allocating 50% of growth capex toward low-carbon investments. Equinor has invested heavily in carbon, capture, and storage (CCS), mainly through the Northern Lights full-scale CCS megaproject. It’s also looking to become a leader in offshore wind, growing its installed renewable capacity to between 4 GW and 6 GW by 2026 and 12 GW to 16 GW by 2030 compared to less than a GW in 2020.

Similar to subsea compression, investing in offshore wind is a way for Equinor to use its offshore oil and gas engineer expertise. It’s also a way for Equinor to play to its strengths by taking advantage of the high winds and shallow depths along the NCS.