Liquefied natural gas (LNG) has gained market share as a go-to source of energy for myriad reasons – chief among them is the ability for large amounts of LNG to be transported via ocean carrier to ports around the world. Applying its LNG storage experience to the growing hydrogen economy, Kawasaki Heavy Industries Ltd. (Kawasaki) has obtained approval for a cargo containment system (CCS) that will potentially bring the capacity levels for the ocean transport of liquefied hydrogen on par with the capacity levels of a LNG carrier vessel.

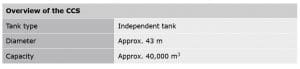

Kawasaki has obtained approval in principle (AiP) from Nippon Kaiji Kyokai (ClassNK) for a CCS that offers the world’s largest capacity (40,000 m3 class per tank), developed for use on a large, liquefied hydrogen carrier.

The CCS for which the AiP was obtained is designed to contain cryogenic liquefied hydrogen, reduced to a temperature of –423.4°F (–253°C) and one eight-hundredth its initial volume, for shipping by sea in large amounts. This containment system has the largest capacity of its kind worldwide used in liquefied hydrogen marine transport. The CCS was developed using design, construction, and safety technologies fostered through building of the Suiso Frontier, a liquefied hydrogen carrier built by Kawasaki that boasts a 1250 m3 carrying capacity.

The AiP was issued by ClassNK following examinations to confirm that the CCS satisfies the IGC Code and the International Maritime Organization (IMO) Interim Recommendations for Carriage of Liquefied Hydrogen in Bulk, and also clears class regulations as well as a risk assessment based on Hazard Identification Study (HAZID) methods.

The CCS enables transportation of cryogenic liquefied hydrogen in large amounts thanks to tank capacity on par with tanks used on large LNG carriers. In addition, it utilizes an independent, self-supporting design with a structure capable of responding flexibly to thermal contraction that occurs when loading cryogenic liquefied hydrogen. It also features a newly developed, high-performance heat insulation system that mitigates boil-off gas (BOG) which occurs in response to heat ingress. The CCS is designed to effectively utilize BOG as fuel to power the ship, thus contributing to reduced CO2 emissions from liquefied hydrogen transport operations.