The Miraculous Hydrogen Fuel Cell

This article was written by Paula DiPerna.

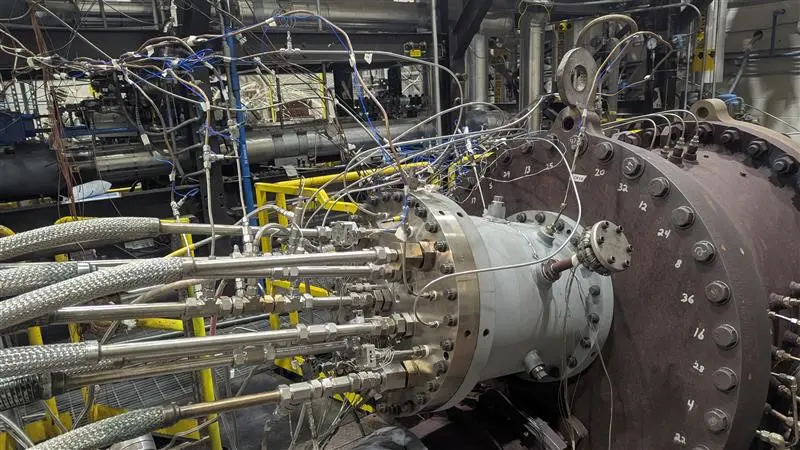

“A stack of these no bigger than a bread box?” So said the executive from Ballard Power Systems at a conference on the potential of hydrogen fuel-cells to run cars, trucks, buses, tractors — almost any vehicle that depended on gasoline. “A stack that small will run your car,” the executive continued. In his hand, he held a single fuel cell — it was just about the same slender look and size as a DVD. A number of them lashed together would presumably be the only engine a car needed. Hydrogen fuel pumps looked just like gas pumps and could be installed at any existing gas station. No fossil fuels involved, so no greenhouse gas (GHG) emissions. Imagine, the only byproduct exhaust was water or water vapor.

I fell in love with the idea of hydrogen fuel cells. How perfect, or so they seemed.

According to the US Department of Energy, “A fuel cell uses the chemical energy of hydrogen or other fuels to cleanly and efficiently produce electricity. If hydrogen is the fuel, the only products are electricity, water, and heat. Fuel cells are unique in terms of the variety of their potential applications; they can use a wide range of fuels and feedstocks and can provide power for systems as large as a utility power station and as small as a laptop computer.”

In short, unlike a battery that can only store power, the fuel cell is its own power plant, able to generate electricity and heat when hydrogen and oxygen bond through an electrolyte.

The National Aeronautics and Space Administration (NASA) in the United States had begun researching and developing hydrogen fuel cells in the 1960s, needing lighter weight alternatives to batteries, and used the cells to power the Gemini and Apollo space capsules on lunar missions. Not only did the cells provide electricity to the capsules, but the astronauts also drank the byproduct as clean water!

An elegant closed system that had the potential to replace fossil fuels in transportation with a fuel cell stack infinitely lighter than a battery that did not need recharging nor much maintenance since there were almost no moving parts.

I was writing for a pioneering environmental newspaper at the time, The Earth Times, and couldn’t wait to attend a symposium at Disney World in Florida featuring all manner of prototypical “green vehicles,” including one of the earliest models of the now ubiquitous Prius, where Toyota unveiled the then latest version of its ingenious hybrid technology that captures waste energy otherwise lost in the braking process and transfers it to the car’s battery to keep it charged and able to kick in to offset gasoline consumption. Almost a perpetual motion machine.

I drove that early beautiful Prius with a very proud Toyota technician, as well as an equally beautiful, even more space age, demo hydrogen-fuel cell sedan produced by BMW. The prototypes were the darlings of the day, and mine too.

But taking fuel cells to scale as substitutes for the earth-bound combustion engine had a major technological drawback. While the energy punch of hydrogen fuel by weight is higher than gasoline, the energy punch is low by volume compared to fossil fuels. This means that the cost per unit of hydrogen-fed power is high, in addition to the environmental and financial costs associated with extracting hydrogen from other elements to which it is bonded, such as methane in natural gas.

Of course, anything to do with natural gas combustion means emissions of GHGs, so the reduced emissions from using hydrogen as the end fuel can be nullified by the emissions generated to produce the fuel in the first place.

Another way to extract hydrogen involves electrolysis, meaning that electricity is used to separate hydrogen from its bond in the water (H2O) molecule. However, if the electricity used in the separation comes from fossil fuels, GHG emissions tag along. Again, a GHG wash, unless hydrogen can be produced fossil-free.

Sir William Grove, a Welsh scientist, invented the first working fuel cell in 1842, but development didn’t continue because the consensus at the time couldn’t see how such a device could generate enough electricity to matter. Ironically, that potentially transformational discovery occurred not that much earlier than the first scientific speculation in roughly 1896 that carbon dioxide emissions into the atmosphere could be bad for planetary health, by Swedish chemist Svante Arrhenius, who had also been interested in electrochemistry.

Since Grove’s original proof of the fuel cell concept, hundreds of patents have been issued worldwide to inventors and innovators, and eventually to industrial giants like GE and UTC for basic research, often in partnership with leading transportation brands. Conquering the obstacles of hydrogen has been a step-by-step process, and so was my love affair.

In 1999, I became president of a major philanthropy in Chicago, and one of my first acts was to track down the status of the three Ballard hydrogen fuel cell buses the Chicago Transit Authority had deployed as part of a testing program, the first time in the United States such buses were being used in real-life revenue service. It’s worth noticing that Vancouver also had a few buses on its streets in this testing phase.

To advertise the pioneering nature of Chicago’s role, our foundation made a small grant to a consortium of local artists to design advertising for the outside of one of the buses, a moving educational billboard, so to speak. We wanted the outside of the bus to proclaim how the inside worked so the drivers and riders of the bus could appreciate the exciting aspect of an ordinary ride.

The design was a gorgeous blue sky with messaging letting all who saw it know the bus was emitting only clean water vapor. The revenue service test phase was important to see how the buses fared in day-to-day demanding use, but still only a few buses were involved.

I visited the Ballard plant in Vancouver, as the company’s end game, of course, was to put fuel cell buses into commercial service. I engaged with local cities to encourage them to order, but the buses remained costly, orders were slow coming in and never enough to justify a full-scale production line. In 1998 there were about only about 30 hydrogen fuel cell buses in service worldwide. The vital breakthrough on cost and engineering remained elusive and my love affair waned.

Fortunately, love can always return, and fuel cell progress does continue. According to the International Energy Association’s annual 2023 Hydrogen Review, “The stock of fuel cell buses grew…with around a 40% increase in 2022 compared with the previous year. As of June 2023, there are around 7018 fuel cell buses worldwide, about 85% are located in China, which added around 1300 fuel cell buses in 2022. Europe has the second largest stock, followed by Korea and then the United States.”

Technology victories continue. The recent Tri-Gen announcement, for example, by Fuel Cell Energy (FCE), a major player in fuel cell technologies, and Toyota, written about in this publication earlier this year, is just about heraldic in the history of fuel cell development.

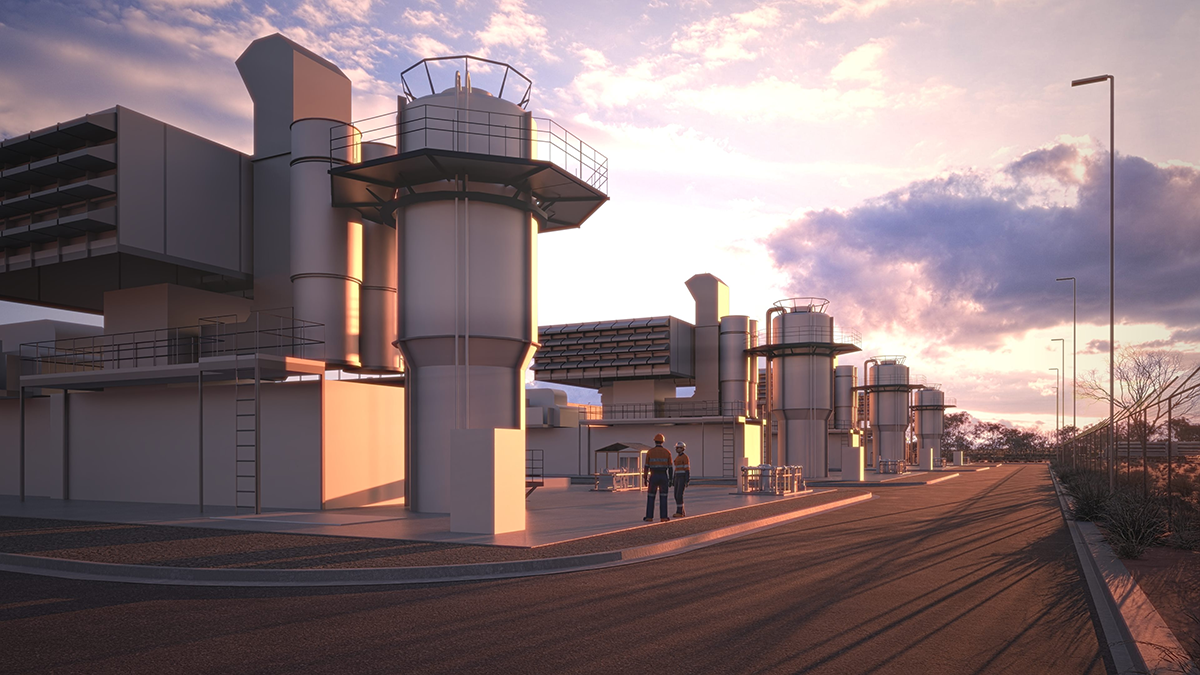

The Tri-Gen system developed by FCE is a world first, producing three products — renewable energy, renewable hydrogen, and usable water, while using biomass to generate the power needed to strip out the hydrogen source fuel from the water input. So, no GHGs are emitted — the ideal “green hydrogen.”

Toyota has deployed the Tri-Gen system at its large vehicle distribution plant in Long Beach, California, making that plant essentially zero emissions, and able to generate surplus power into the local grid for other uses, including power at Long Beach port. And the water generated on the side? Toyota uses it to wash the cars coming through for final check and processing. Gradually, the water could have other uses, especially as drought and hot weather become more common.

Given that roughly 25% of the world’s GHG emissions derive from the transportation sector, truly green hydrogen used to generate vehicular power would be a remarkable step change.

What holds us back? True, there are significant technological and engineering hurdles on fuel cells still, despite innovations such as Tri-Gen that provide invaluable learning so progress can continue. But it’s high-speed acceleration of research and field testing that we need.

As with all promising technologies intended to address climate change, acceleration is held back by the absence of a coherent international system to incorporate the costs of climate change into our conventional financial reckoning, notably through at the very least an international system of carbon pricing. If every tonne of greenhouse gas emitted carried a price tag concomitant to the costs being generated by that tonne, the price of emitting would climb, and new technologies to reduce emissions would therefore become more notably cost effective and more in general demand. Then, mainstream investment would flow more readily to promising new technologies that reduce climate-change related costs.

And how those costs can dazzle. According to data in 2023 from the World Economic Forum, climate change costs the world roughly US$16 million per hour already, including damages to infrastructure, agriculture, and human health. An April 2024 study from the Potsdam Institute on Climate Impact Research, published in Nature, puts projected annual economic losses due to climate change at US$38 trillion per year by 2050.

Compared to such potential losses, the cost of testing, producing, marketing, servicing, and deploying hydrogen fuel cells is like a pebble in the palm of your hand.

As unfathomable as the costs of climate change may be, they remain largely invisible to our current conventional accounting and tracking systems, so those costs do not yet hit the real economy and remain, other than in research, out of our accustomed financial reckoning. Carbon pollution looks far cheaper than it is.

If that false impression were stripped away, mainstream investment in such promising technologies as hydrogen fuel cells, invented nearly two centuries ago and left to languish, would be dramatically unleashed.

In the meantime, we must rely on the continuing imagination of the engineers and visionary investors who support them to help keep our eyes on that hydrogen horizon.

Here’s to their love of the work — our world depends on it.