Nu:ionic Hydrogen-Producing Microwave Reactor Reaches Commercial Threshold

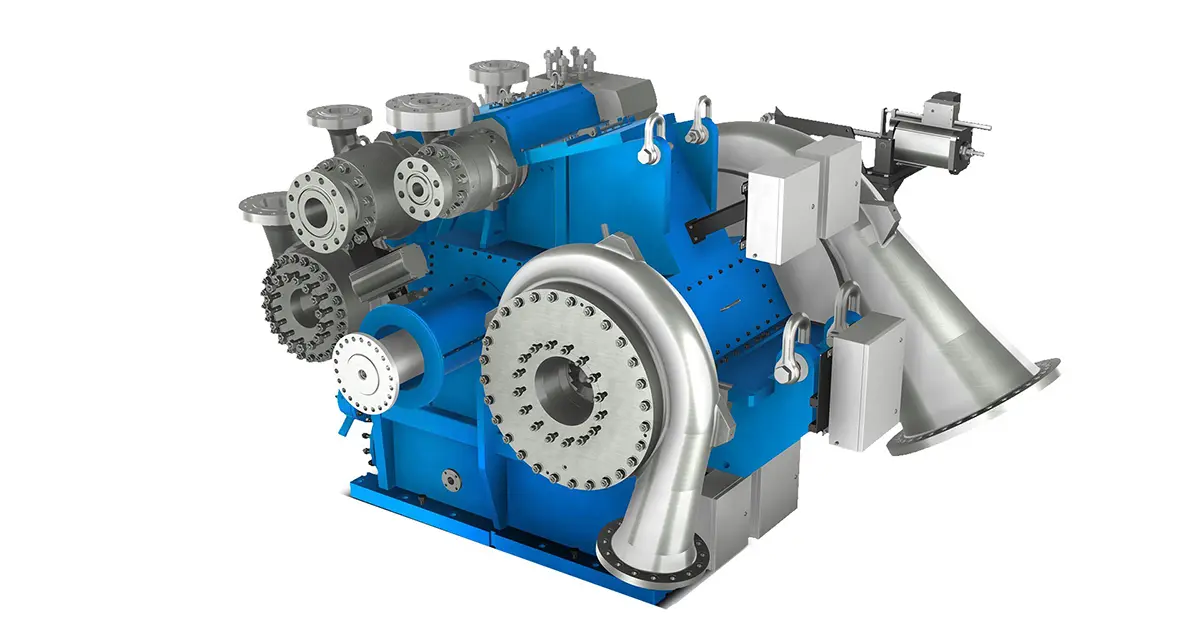

Nu:ionic Technologies Inc. (Nu:ionic) has completed a continuous 48-hour demonstration run of its proprietary microwave catalytic reformer (MCR). According to Nu:ionic, this commercial scale, 100-kW electrified reactor can be used in many applications for low-carbon hydrogen production from various feedstocks, including biogas, natural gas, or renewable ammonia. The reactor is undergoing testing and accumulating run time in the company’s Fredericton, New Brunswick, Research and Innovation Center.

The next step is the installation of a fully integrated demonstration unit at a customer site in Western Canada. The installation includes a hydrogen purification and carbon capture system. The carbon capture system produces readily transportable liquid carbon dioxide for reuse or sequestration.

“This is exciting progress in offering zero-emissions, electrified process technologies for energy-intensive applications such as steam methane reforming [SMR], eliminating the need for the combustion of fossil fuels to generate thermal energy,” said Jim Tranquilla, president and chief technology officer at Nu:ionic. “The MCR is an example of an innovative use of industrial microwave technology for natural gas reforming and other applications. MCR is one of the electrification technologies under development in our lab to offer decarbonization solutions that can be implemented now, not in a few years.”

Nu:ionic’s MCR technology is well-suited for small-scale, low-carbon hydrogen production, ranging from 1 to 10 tonnes per day (TPD), and accommodates low-cost hydrogen carriers such as renewable ammonia, methanol, biogas, or natural gas as feedstock and can be used for hydrogen blending, clean fuel generation, pre-combustion carbon capture, chemical feedstock, or energy storage. The MCR process uses approximately 30% less natural gas as compared to conventional reformer methods, reducing the associated upstream emissions of natural gas exploration, production, and transmission, while also eliminating the need for cost-prohibitive post-combustion carbon capture. The MCR package is also significantly more compact as compared to the conventional SMR equipment footprint.

“Our mission is to clean the air, and today the future is looking even brighter,” said Nu:ionic Chief Executive Officer Jan Boshoff. “Renewable electricity is a low-carbon energy feedstock that is available now, making it possible for our customers to meet their decarbonization goals by producing low-carbon hydrogen at low cost. Our hydrogen production solutions are cleaner, significantly less expensive than alternatives, and leverage existing infrastructure investments.”