Japan/Australia Hydrogen Supply Chain Project Hits Major Milestone

The Hydrogen Energy Supply Chain (HESC) Pilot Project has commenced Australian operations. When fully operational, the HESC Pilot Project will be a complete hydrogen supply chain, delivering liquefied hydrogen from Australia to Japan. Kawasaki Heavy Industries (KHI) is running the pilot project, with government support from both Japan and Australia, in the Australian state of Victoria, home to a quarter of the world’s known brown coal reserves.

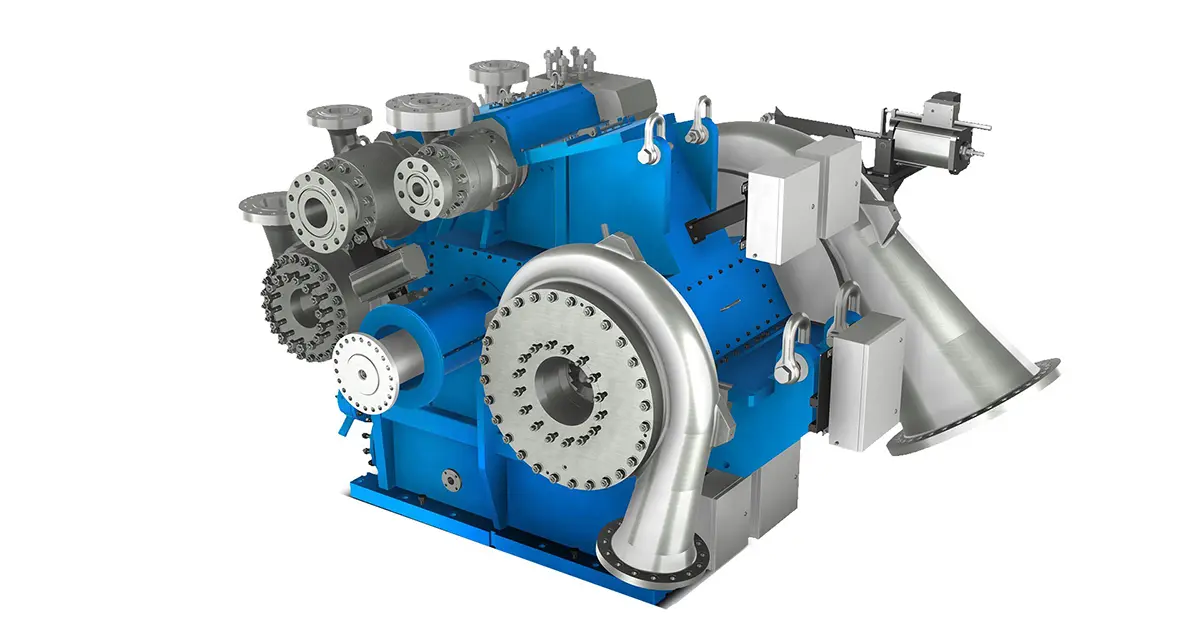

Hydrogen gas is being produced from brown coal by gasification at a newly constructed plant located Australia’s Latrobe Valley. Coal gasification works by reacting coal with oxygen under high pressures and temperatures to form synthesis gas (syngas), a mixture consisting primarily of carbon monoxide and hydrogen. The pilot gasification plant uses a total of up to 176 tons (160 tonnes) of brown coal and includes a drying and milling system developed specifically for Victorian brown coal.

One of the goals of the project is to demonstrate the production of hydrogen from syngas. During gas refining, the syngas is purified and the carbon monoxide in the gas mixture is reacted with steam to produce additional hydrogen and carbon dioxide. The carbon monoxide is converted to carbon dioxide with steam, then the hydrogen is separated. The hydrogen produced is refined to achieve a high purity specification for transportation.

Hydrogen gas from the Latrobe Valley is then transported to the newly constructed liquefaction, storage, and loading facility at Port of Hastings by truck in high pressure tube trailers. There, the hydrogen gas is converted to liquefied hydrogen. The liquefaction process cools the hydrogen gas to −423°F (−253°C) and reduces it to 1/800th of its gaseous volume.

Liquefied hydrogen will be held in a storage container before being loaded onto a marine carrier for transport to Japan. KHI is developing a specialized system to load the liquefied hydrogen onto a carrier.

HESC will be the first initiative to transport mass quantities of liquefied hydrogen across open waters. Australia and Japan have worked together to develop interim carriage requirements. In November 2016, the International Maritime Organization approved these requirements, allowing the bulk transport of liquefied hydrogen from Australia to specially designed facility in Kobe, Japan.

KHI’s purpose-built liquefied hydrogen carrier, the Suiso Frontier, will make the end-to-end journey. To prevent boil off during transport, KHI developed specialized insulation technology. The 44,143 cu.ft. (1250 m3) storage tank features a double-shell structure with vacuum insulation between the overlapping inner and outer shell layers. The inner-tank supports are made of glass-fiber-reinforced plastic. Liquefied hydrogen is kept at −423°F.

The Suiso Frontier carried out trial operations in October last year and is effectively complete. COVID-19 safety measures have delayed final approvals. The Japanese government suspended the entry of foreign nationals as part of its COVID-19 protocol, barring KHI from receiving engineers from overseas manufacturers for the final approval of machinery installation on the vessel.

“The next major HESC pilot development will be the first shipment of hydrogen between Australia and Japan,” said Hirofumi Kawazoa from Hydrogen Engineering Australia, Kawasaki’s subsidiary company based in Melbourne. “The eyes of the world will be on Victoria, when shipments of liquefied hydrogen commence this year. The HESC Pilot is proving it is possible to take Latrobe Valley coal and produce and transport hydrogen. It is yielding data and insights that feed into the pathway to commercialization.”