Flare Emissions Monitoring Breakthrough

Baker Hughes has announced a breakthrough in flare emissions monitoring following a collaboration with bp. Using Baker Hughes’ emissions abatement technology, flare.IQ, bp is quantifying methane emissions from its flares, a new application for the upstream oil and gas sector.

With no universally accepted solution to quantifying methane emissions from flares, bp and Baker Hughes conducted one of the largest ever full-scale studies of flare combustion, including testing a range of flares under challenging conditions and verifying the accuracy of flare.IQ technology. Now, acting on real-time data from flare.IQ at 65 flares across seven regions, bp can carry out early interventions and reduce emissions from flaring.

“bp’s transformation is underway, turning strategy into action through delivery of our targets and aims,” said Fawaz Bitar, bp senior vice president of health safety environment and carbon. “We don’t have all the answers, and we certainly can’t do this on our own. Through our partnership with Baker Hughes, we have progressed technology and implemented methane quantification for oil and gas flares, helping us to achieve the first milestone of our Aim 4. We continue to look at opportunities like this, where we can collaborate across the industry to find solutions to our biggest challenges.”

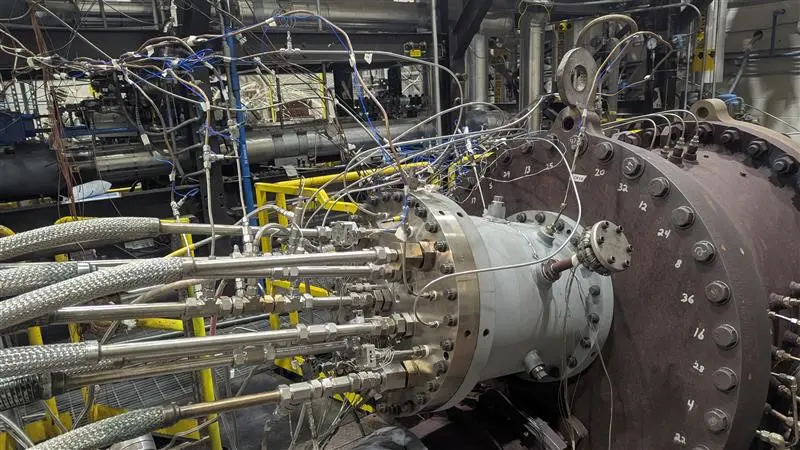

Part of Baker Hughes’ Panametrics product line portfolio, flare.IQ builds on four decades of ultrasonic flare metering technology experience. It is designed to monitor and optimize combustion efficiency and performance of the entire flare system 24/7. According to Baker Hughes, the system can help both downstream refinery and upstream production facilities meet regulatory requirements and significantly reduce the threat of methane emissions, as well as drive down operation costs by reducing steam and supplemental gas consumption.

flare.IQ’s advanced analytics platform enables operators to pull critical information from their flare systems, including temperature, pressure, vent gas velocities, and gas composition, helping maximize combustion efficiency and minimize emissions. flare.IQ enables emissions reporting based on real-time measurements, in compliance with OGMP 2.0 Level 4.

Alongside flare.IQ, Baker Hughes has a broad portfolio of emissions abatement technologies capable of improving productivity, efficiency, and value at scale across customer operations. Using modular gas processing, Baker Hughes’ turbomachinery emissions control technologies can capture exhaust gas that would normally be flared and use it as a highly efficient power source. Its compression technology upgrades can also help reduce fugitive venting on installed equipment. Baker Hughes’ flow and process solutions, like Becker valves and Masoneilan valves, allow the company to replace or retrofit emissions control systems in natural gas operations with no-bleed valves to cost-effectively reduce methane emissions.

Baker Hughes is focused on reducing emissions and increasing efficiency. According to the company’s website, 40% of oil and gas emissions could be reduced using existing technologies at no net cost. Emissions abatement technologies and investment in solutions that are both economically and environmentally beneficial can help industries get on track to reach Paris Agreement targets.