Oxford University’s Breakthrough Solar Energy Discovery

Scientists at the Oxford University Physics Department have developed an approach which could generate increasing amounts of solar electricity without the need for silicon-based solar panels. Their innovation works by coating a new power-generating material onto the surfaces of everyday objects such as rucksacks, cars, and mobile phones.

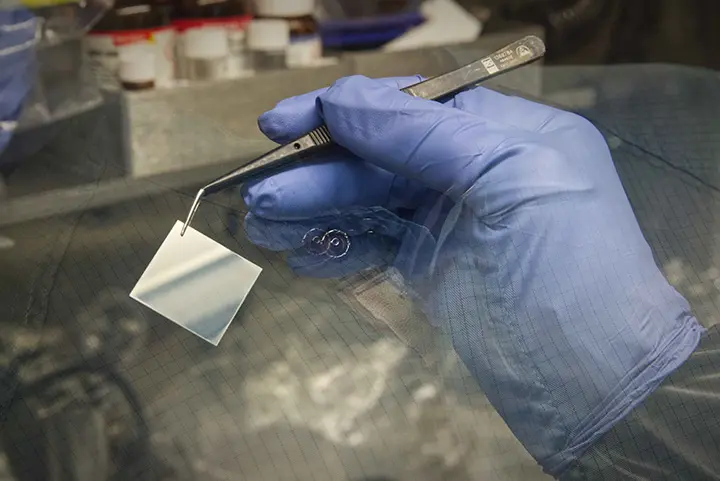

According to Oxford, the light-absorbing material is thin and flexible enough to apply to the surface of almost any building or common object. Using a technique developed in Oxford, which stacks multiple light-absorbing layers into one solar cell, the researchers have harnessed a wider range of the light spectrum, allowing more power to be generated from the same amount of sunlight. This ultra-thin material, using this so-called multi-junction approach, has now been independently certified to deliver over 27% energy efficiency, for the first time matching the performance of traditional, single-layer, energy-generating materials known as silicon photovoltaics. Japan’s National Institute of Advanced Industrial Science and Technology gave its certification prior to publication of the researchers’ scientific study later this year.

(Copyright Oxford University Physics)

“During just five years experimenting with our stacking or multi-junction approach we have raised power conversion efficiency from around 6% to over 27%, close to the limits of what single-layer photovoltaics can achieve today,” said Dr. Shuaifeng Hu, Post-Doctoral Fellow at Oxford University Physics. “We believe that, over time, this approach could enable the photovoltaic devices to achieve far greater efficiencies, exceeding 45%.”

The researchers faced multiple challenges in the five years of experimenting before achieving the recent breakthrough. “One of our biggest challenges has been fabricating a high-quality perovskite rear subabsorber film, as the crystallization of this film is difficult to control and highly sensitive to air,” said Dr. Hu. “In this work, we have successfully managed the crystallization process using our newly invented crystallization modifier. Additionally, we have minimized the exposure of the perovskite material to air through our automated national cluster facility, which allows us to deposit most layers under vacuum using various deposition techniques that are connected.”

Today’s solar panels have around 22% energy efficiency (meaning they convert around 22% of the energy in sunlight). The new ultra-thin material is not only more energy efficient, but also more versatile. At just over one micron thick, it is almost 150 times thinner than a silicon wafer. Unlike existing photovoltaics, generally applied to silicon panels, this can be applied to almost any surface. “The exceptionally high absorption coefficient and direct bandgap nature of this perovskite material enable us to absorb large amounts of sunlight efficiently with an ultra-thin layer,” said Dr. Hu.

“By using new materials which can be applied as a coating, we’ve shown we can replicate and out-perform silicon whilst also gaining flexibility. This is important because it promises more solar power without the need for so many silicon-based panels or specially built solar farms,’ said Dr. Junke Wang, Marie Skłodowska Curie Actions Postdoc Fellow at Oxford University Physics.

The researchers believe their approach will continue to reduce the cost of solar and make it the most sustainable form of renewable energy. According to the World Economic Forum, the global average cost of solar electricity has fallen by almost 90% since 2010, making it almost a third cheaper than that generated from fossil fuels. Innovations promise additional cost savings as new materials, like thin-film perovskite, reduce the need for silicon panels and purpose-built solar farms.

“We can envisage perovskite coatings being applied to broader types of surfaces to generate cheap solar power,” said Dr. Wang. “If more solar energy can be generated in this way, we can foresee less need in the longer term to use silicon panels or build more and more solar farms.”

One inherent issue with generating solar energy from a solar farm is that the energy isn’t immediately used. A lot of energy is lost during the conversation, transmission, and storage processes. Greater energy efficiency can be achieved by eliminating the transmission and storage elements of the equation using a coating.

“This technology enables us to fabricate flexible solar cell devices that can be easily applied to or integrated with almost any surface—for example, the roofs of cars or the backs of phones—allowing them to instantly generate electricity by harvesting energy from the sun,” said Dr. Hu. “We could achieve over 50% efficiency by adapting the newly invented multi-junction photovoltaic technology. For instance, by optimally connecting four different perovskite subabsorber layers, we could fabricate solar cell devices with an energy efficiency of approximately 55%.”

Another potential environmental impact of using perovskite coatings on existing objects is that is avoids resource-intensive processes associated with building utility-scale solar farms. “By leveraging the exceptionally high energy efficiency and superior compatibility of this coating technology, we can free up more land by reducing or eliminating the need for solar farms,” said Dr. Hu. “At the same time, we can save a significant number of resources typically consumed in photovoltaic manufacturing.”

The researchers are among 40 scientists working on photovoltaics led by Professor of Renewable Energy Henry Snaith at Oxford University Physics Department. “As scientists, we enjoy in exploring the unknown and transforming the seemingly impossible into reality, ultimately contributing to a more sustainable future for humanity,” said Dr. Hu.

Their work in photovoltaics and especially the use of thin-film perovskite began around a decade ago and benefits from a bespoke, robotic laboratory. Their work has strong commercial potential and has already started to feed through into applications across the utilities, construction, and car manufacturing industries.

“The latest innovations in solar materials and techniques demonstrated in our labs could become a platform for a new industry, manufacturing materials to generate solar energy more sustainably and cheaply by using existing buildings, vehicles, and objects,” said Henry Snaith, Professor of Renewable Energy, Oxford University Physics Department.

Snaith is the co-founder and chief scientific of Oxford PV, a UK company spun out of Oxford University Physics in 2010 to commercialize perovskite photovoltaics. It recently started large-scale manufacturing of perovskite photovoltaics at its factory in Brandenburg-an-der-Havel, near Berlin, Germany, making it world’s first volume manufacturing line for ‘perovskite-on-silicon’ tandem solar cells.

“We originally looked at UK sites to start manufacturing, but the government has yet to match the fiscal and commercial incentives on offer in other parts of Europe and the United States,” said Professor Snaith. “Thus far the UK has thought about solar energy purely in terms of building new solar farms, but the real growth will come from commercializing innovations – we very much hope that the newly-created British Energy will direct its attention to this.”

“Supplying these materials will be a fast-growth new industry in the global green economy and we have shown that the UK is innovating and leading the way scientifically. However, without new incentives and a better pathway to convert this innovation into manufacturing the UK will miss the opportunity to lead this new global industry,” Professor Snaith added.