An LNG First

Siemens Energy will supply a gas/electric hybrid drive system for a liquefied natural gas (LNG) plant being built in Charlton, Massachusetts, by Northeast Energy Center (NEC) and Chart Energy & Chemicals. According to Siemens Energy, the NEC project will be the first LNG facility in the world to feature a system of this type.

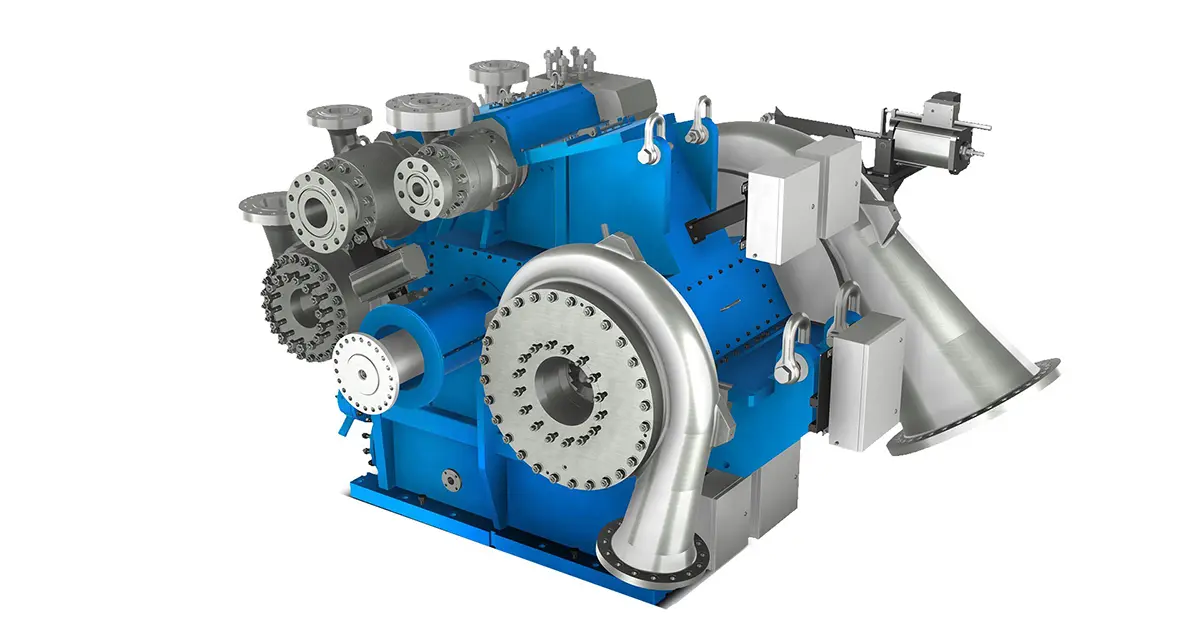

Siemens Energy will serve as the single-source supplier of the integrated drive, providing all rotating equipment and associated control systems. The hybrid drive system will combine a Siemens Energy low-emissions industrial gas turbine, integrally geared compressor, and electric motor-generator to ensure operation of the plant’s main refrigeration/liquefaction train throughout the year.

Available power from gas turbines decreases as the ambient temperature increases. As a result, units installed at industrial facilities are often oversized to ensure sufficient power during the hot and humid weather. However, the same gas turbine may generate much more power during cold time than is required, leading to reduced efficiency and increased emissions. The hybrid drive refrigeration compressor system being supplied for NEC offers a solution to this problem by combining an electric motor-generator with a gas turbine that features a dry-low emissions design with lowest achievable NOx emissions levels.

The NEC facility is expected to produce a baseload of 170,000 gallons of LNG per day for Boston Gas under a firm contract and up to 250,000 gallons per day to other utilities. The gas turbine’s output will decrease when LNG production increases to 250,000 gallons per day on hot summer days when the motor-generator will function as a motor to supply additional power to the compression system.

The plant has an onsite LNG storage capacity of 2 million gallons. The LNG produced will be available for delivery by truck and used as a feedstock for utility distribution companies and power generation facilities.

The LNG facility will be is comprised of a feed gas pretreatment system, a gas liquefaction system, a full-containment LNG storage tank, an LNG truck-loading station with four bays, a process control system; stormwater management infrastructure, and other ancillary systems. Additional structures will also be constructed on the site, including a control room building, power distribution and control building, and a nitrogen compressor building.