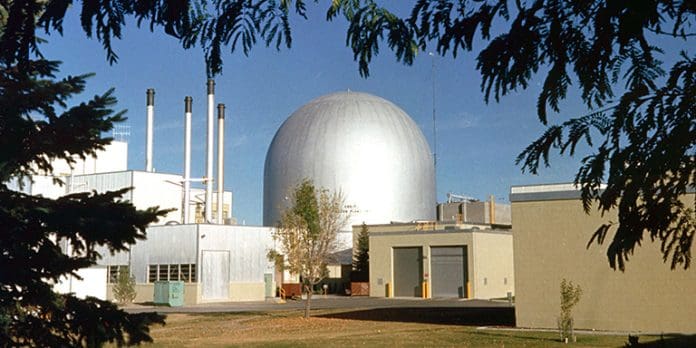

The US Department of Energy (DOE) approved the conceptual design for Oklo Inc.’s (Oklo’s) Aurora Fuel Fabrication Facility. The new facility will be located at Idaho National Laboratory (INL) and will help turn used material recovered from DOE’s former Experimental Breeder Reactor-II (EBR-II Reactor) into usable fuel for its advanced nuclear power plant. Oklo anticipates the first commercial Aurora powerhouse will be deployed in 2027.

(Image courtesy of Idaho National Laboratory)

Fuel For Aurora

The Conceptual Safety Design Report was first submitted earlier this year to DOE’s Idaho Operations Office, which is responsible for the nuclear safety and regulatory authority for the project. The approval of the design concept is an important step in demonstrating advanced fuel recycling technologies.

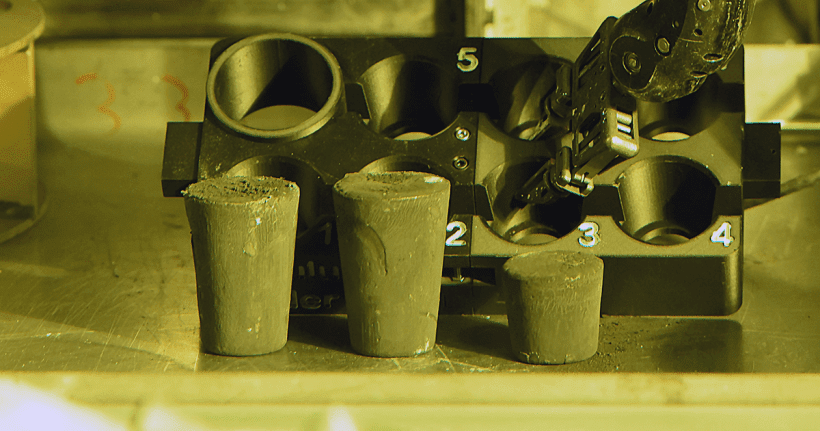

The Aurora powerhouse is a liquid-metal-cooled fast reactor that is designed to operate on both fresh high-assay low-enriched uranium (HALEU) and used nuclear fuel. The new facility will fabricate fuel using HALEU sourced from EBR-II.

Oklo has been granted access to 5.51 tons (5 tonnes) of HALEU as part of a cooperative agreement with INL that was competitively awarded in 2019. The newly fabricated fuel will be used to power the initial Aurora powerhouse reactor core at INL.

“We are proud of our collaboration with INL and DOE as we move closer to turning on our first commercial plant that uses this recovered nuclear fuel in just a few years,” said Jacob DeWitte, co-founder and chief executive officer of Oklo.

Oklo will continue to work with INL to complete the facility design and obtain DOE approval before the start of construction.

Last month, Oklo finalized agreements with DOE to begin site characterization of their preferred location for the Aurora powerhouse reactor to support their combined license application to the US Nuclear Regulatory Commission.

DOE will retain ownership of the HALEU both during and after its use.

Oklo has also received previous DOE support through several Gateway for Accelerated Innovation in Nuclear (GAIN) vouchers to advance its Aurora powerhouse design, along with additional funding to demonstrate recycling technologies through ARPA-E.

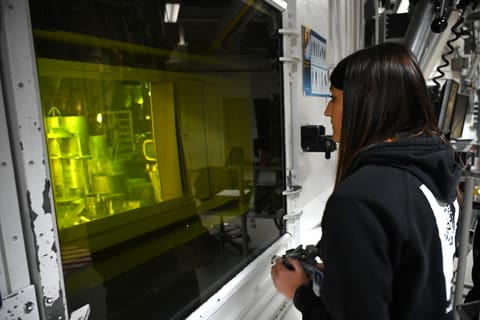

(Image courtesy of Idaho National Laboratory)

Status Of The EBR-II Reactor

According to the DOE, the EBR-II reactor is in a safe storage configuration with all primary and secondary systems drained of sodium, a passivation layer consisting of sodium bicarbonate exists on exposed sodium surfaces, and all primary and secondary systems inerted with a cover gas blanket. Full decommissioning and demolition of the facility will be resumed when necessary funding is obtained. The EBR-II was shutdown in late 1994 after 30 years of successful operation. The detailed Safe Storage Work Plan describing the final condition of the EBR-II was implemented in October 2000. By that time many important steps had already been performed. Specifically, de-fueling of the reactor, the design and construction of the sodium process facility and initial sodium processing had taken place. By the end of January 2001, the bulk primary system and secondary system sodium had been processed and packaged in the Sodium Process Facility (SPF) for disposal. Residual sodium was treated by passivation using a moist carbon dioxide treatment method. The objective was to leave all systems in a known, well documented configuration for future decommissioning, to minimize surveillance and maintenance activities and expenditures, to close sodium bearing systems for a minimal 20-year period and provide recommendations for future reactor designs based upon the operating experiences from the plant.