Chart Technology For New Louisiana LNG Facility

Chart Industries (Chart) will provide its mid-scale modular liquefaction solution for Argent LNG’s 20-MTPA liquefied natural gas (LNG) facility in Port Fourchon, Louisiana. Chart’s modular mid-scale LNG achieves total plant liquefaction capacity through multiple identical trains, rather than a single large train.

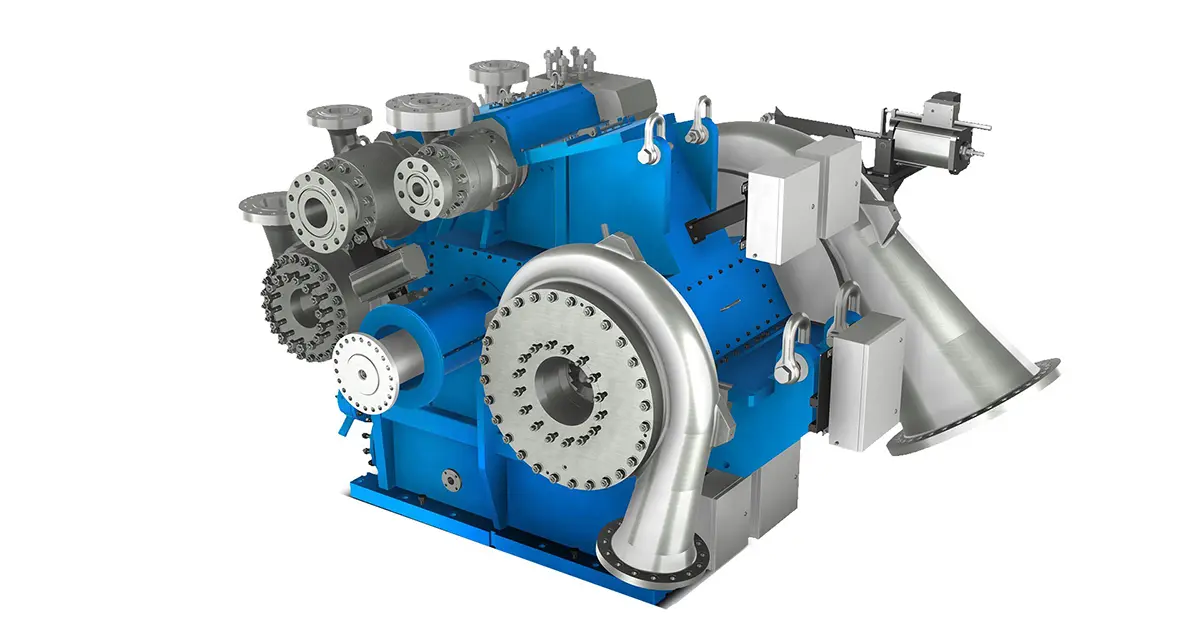

Chart’s integrated pre-cooled single mixed refrigerant (IPSMR) process technology, proprietary braised aluminum heat exchangers, and cold boxes are integral elements of its mid-scale LNG offering. IPSMR process technology can be configured to match available gas turbine power with single cold box capacity to 3 MTPA.

Each liquefaction train is paired with a heavy hydrocarbon removal system (HHC) to remove freezing components from the feed gas before liquefaction. The HHC comprises a scrub column, braised aluminum feed gas exchanger, and reflux drum in a fully assembled cold box module. According to Chart, reflux for the scrub column is not reliant on the condensate system or LNG. Specifically designed to remove freezing components from feed gas, the HHC maximizes LNG and reduces the condensate handling system, the company said. The HHC can be fitted with an expander compressor and/or booster compressor to improve liquefaction efficiency and LNG production.

“We are excited to partner with Argent LNG to provide our IPSMR technology, brazed aluminum heat exchangers, cold boxes, and air coolers,” said Jill Evanko, president and chief executive officer of Chart. “Argent is strategically optimizing a 20-MTPA LNG facility by moving entirely to modular resulting in a smaller footprint, higher efficiency, and less cost, therefore offering its customers the most efficient and effective solution.”

Spanning 144 acres (58 ha), the project site is situated within 22 miles (35 km) of Enbridge infrastructure and 13 miles (21 km) from Kinder Morgan lines, facilitating economical transportation of natural gas to the liquefaction plant.

In June 2024, Argent LNG selected Worley as its development partner. Worley’s initial scope of work will focus on developing the site layouts and selecting the technology. It will also initiate the US Federal Energy Regulatory Commission process. The plant is expected to begin operations in 2029/2030.