Baker Hughes Opens Hydrogen Testing Facility

This article was written by Drew Rob.

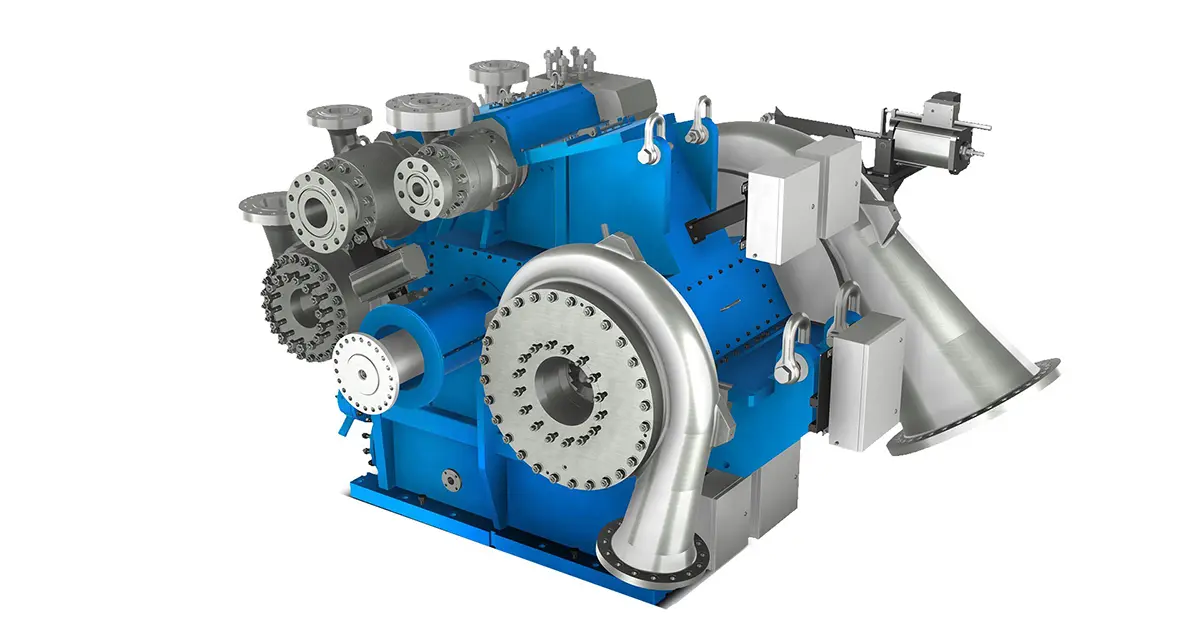

Baker Hughes has opened a new hydrogen testing facility in Florence, Italy, to support the deployment of hydrogen-ready technologies, such as its NovaLT turbines. While the NovaLT16 has been tested successfully with 100% hydrogen using a partial-premix combustor, further work is ongoing to develop the NovaLT16 running on a hydrogen DLN combustor to further reduce NOx emissions, as well as other testing of additional turbines of the NovaLT family and a range of other Baker Hughes equipment. A new test bench at the site allows full-load testing and features a storage capacity of 5401 lb. (2450 kg) at 4351-psi (300-bar) pressure.

The hydrogen storage system was built next to the turbine test benches. It consists of a reciprocating compression unit, containers for hydrogen storage, a reduction skid, a vent tower, and a loading bay for hydrogen delivery. It has a capacity of 2.5 tons (2.3 tonnes) at 300 bar and a delivery pressure of 798 psi (55 bar). A blending station is available onsite that is used to switch between hydrogen and natural gas or blend them at various percentages.

“This new facility allows us to test turbines in all project conditions while serving as a hub for collaboration with customers in the growing hydrogen economy,” said Raimondo Giavi, vice president of hydrogen at Baker Hughes. “As well as technical validation of new Baker Hughes technology, the testing site is used to perform full-scale testing for turbines that are going to be delivered to customer sites.”

Following the successful testing of the NovaLT16, Baker Hughes now offers a NovaLT16 package that can operate 100% on hydrogen. The first solutions are destined for Air Products’ Net-Zero Hydrogen Energy Complex in Edmonton, Canada. These NovaLT16 turbines underwent full-load testing using a partial premix burner developed by Baker Hughes.

Meanwhile, development work is ongoing on a dry low emissions (DLE) combustor to enable it to run on 100% hydrogen. This is being done as part of a European Union funding project named HyPowerGT that Baker Hughes is conducting alongside eight other partners. Product availability is expected by 2026.

Baker Hughes believes it is ahead of all other turbine original equipment manufacturers when it comes to hydrogen readiness. It started with the PGT10B from Nuovo Pignone (the legacy name for Baker Hughes facilities in Italy) which has been running on 100% hydrogen in a real commercial project for two years. The company has cumulated more than 70 turbines operating on hydrogen of various percentages.

“There is a lot of interest in hydrogen-ready turbines for applications such as pipelines, long-duration energy storage, load peaking, distributed power, and marine propulsion,” said Giavi.

In addition to gas turbines, the company’s experience with hydrogen dates back more than a century. Its hydrogen portfolio includes compressors, turbines, valves, centrifugal pumps, non-metallic pipes, hydrogen sensors, monitoring and diagnostics, and inspection solutions for hydrogen embrittlement in production and storage.

NovaLT Family

The NovaLT family of turbines range from 5 to 20 MW. They can be used in power generation or in mechanical drive mode for applications in pipelines, gas storage and other oil and gas operations. They can achieve efficiency rates of 37% (simple cycle) and up to 85% in cogeneration applications due to the turbines having a high exhaust temperature of 923°F (495°C).

The NovaLT16 is the most popular of the family with the largest number of units in the field.

“This turbine model has the best performance in its power range, combining the advantages of heavy-duty gas turbines [long time between maintenance intervals] and aeroderivative [high efficiency and ability to swap the engine in 24 hours],” said Giavi.

It offers 16.9 MWe of capacity in simple cycle, a rotating speed of 7800 rpm, an average of 35,000 hours mean time between maintenance intervals for the hot gas path, and 70,000 hours between major inspections. There is no need for intermediate borescope inspections or seasonal dry-low NOx (DLN) tuning. The NovaLT16 typically uses a single annular, DLN emissions combustion system, capable of less than 15-ppm NOx at 15% oxygen emissions for natural gas fuel (from 50% to 100% load) in power generation applications (a 9-ppm option is available).

The engine is equipped with variable nozzle guide vanes to eliminate bleeding and boost efficiency at part load. Consequently, it boasts 35% average lower greenhouse gas (GHG) emissions for the NovaLT16 compared to heavy-duty gas turbine offerings of a similar size such as the PGT10 turbine (the first turbine to run on 100% hydrogen in a commercial project back in 2009). Only 45 days are said to be needed from order placement to installation. A 3-day engine swap capability is available if needed.

Two packages are available. The power generation package has a 15.62 m x 3.15 x 9.52 footprint and weighs 134.2 tons. The mechanical drive package footprint is slightly longer at 18.2 m x 3.15 x 4.1 and weighing 52.9 tons. The power output in mechanical drive is slightly more at 17.5 MW and efficiency is 37.4%.

Two other NovaLT models are currently offered. The NovaLT5-1 offers 5.1 MW and 29.5% efficiency. The NovaLT12 provides 12.5 MW and 35.3% efficiency. The NovaLT5 is mainly used for industrial power generation and combined heat and power. The NovaLT12 finds applications in power generation, as well as in mechanical drive for pipelines such as replacing an aging frame turbine, or for gas storage applications. For example, the NovaLT12 has been deployed in pipeline applications in both Italy and Greece.

Orders Deluge

Meanwhile, Baker Hughes is enjoying a surge in turbomachinery orders. Its Industrial & Energy Technology (IET) division recorded more than US$14 billion in sales in 2023 for gas turbines, compressors, and other energy production and monitoring technologies. This is 12% higher than 2022 and includes: an order for the 9.6-MTPA Ruwais liquefied natural gas (LNG) project in the United Arab Emirates including two electric liquefaction systems, the first all-electric LNG project in the Middle East; a contract for SBM Offshore for turbogenerators, turbocompressors, electric motor-driven compressors, and commissioning and spare parts for floating production, storage, and offloading (FPSO) vessels; several other contractual service agreements for the maintenance of LNG projects in the Middle East, North America, and Europe; an electric motor-driven sour gas booster compression package to support offshore natural gas fields in the Middle East; the company’s Cordant digital solutions reached a multi-year deal with Shell to centralize the Baker Hughes System 1 asset condition and performance monitoring systems across 33 sites; and a System 1 deal with India’s Oil and Natural Gas Corporation Limited for 12 offshore platforms.

Yet another huge order is expected from Saudi Aramco and rumored to be the biggest turbomachinery order in company history. A formal announcement is coming soon but the order will be for at least 17 gas compression trains.

In addition, Baker Hughes will probably profit from the massive expansion plans unveiled by QatarEnergy LNG (formerly Qatargas). This comprises 16 new offshore sites for gas production and six LNG trains with capacity of 8 MTPA each to take the nation’s total to 142 MTPA by 2030. Carbon capture and storage technology is also included.

Orders are coming in on the hydrogen front, too. Baker Hughes reported delivery of the first two trains of advanced hydrogen compression solutions for the NEOM project in Saudi Arabia. This is said to be the largest green hydrogen project in the world. It is a joint venture of ACWA Power, Air Products, and NEOM. The company is also its manufacturing capabilities in Modon, Saudi Arabia, to add localized testing and packaging capabilities.

A collaboration agreement with HyET has been inked for development of an advanced hydrogen electrochemical compression solution. And Green Energy Park signed an agreement for collaboration on the production, storage, transportation, and utilization of green hydrogen and ammonia-based fuels.

“These low-carbon and carbon-free energy advancements illustrate how the urgency of the energy transition has transformed customer relationships into comprehensive partnerships for innovation across several projects,” said Lorenzo Simonelli, chair and chief executive officer of Baker Hughes. “There is no path to net zero without innovation and collaboration, and our work with customers and partners, including Air Products, is proving the validity the hydrogen economy and of our strategy to invest and develop innovative solutions to cover the entire hydrogen value chain.”