Danos 3D Printing Technology For Coastal Restoration Projects

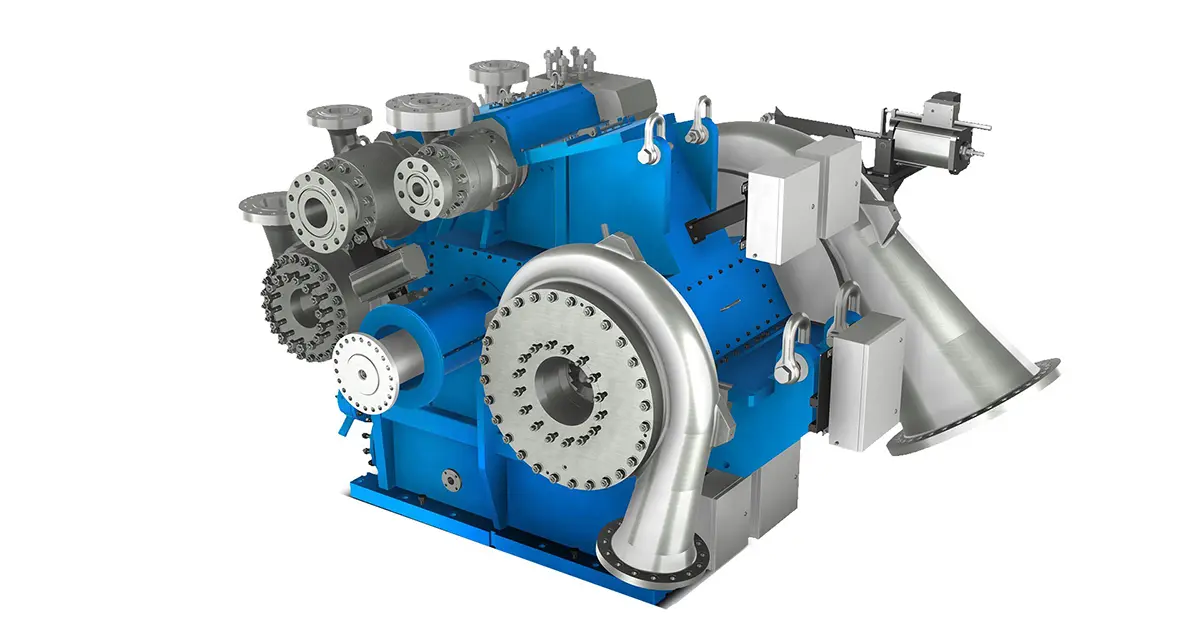

Danos has established a resilience technology center of excellence in Amelia, Louisiana. In partnership with climate technology company, Natrx Inc., Danos is producing high-performance, nature-based modules for coastal resilience and restoration projects using a patented, highly specialized 3D printing technology called DryForming. The DryFormer and its components arrived on site from Natrx in early October, and Danos began producing its first modules a week later. This new production capability will fabricate tailored concrete modules called ExoForms (nicknamed Cajun Coral) to restore natural habitats along coastal and riverine waterways.

The 5000-sq.ft. (465-m) facility can produce up to 50,000 tons (45,359 tonnes) of Natrx’s Cajun Coral, equivalent to 500,000 tons (453,592 tonnes) of heavy rock supply that is typically purchased out of state. Located along Bayou Beouf, the facility has direct access to the Intracoastal Waterway and the Gulf of Mexico, enabling Danos to ship units worldwide.

Currently, Danos is printing Cajun Coral for several resilience projects, including a project with the Coastal Conservation Association to enhance fish habitat and biodiversity in the Gulf of Mexico. In addition to industrial-scale Cajun Coral production, the facility will build, test, and deploy new, mobile DryForming units, allowing Danos to address resilience challenges globally.

“The DryFormer solves challenges addressing coastal restoration, pipeline protection, and artificial reef construction right here in south Louisiana and around the world,” said Eric Danos, chief executive officer (CEO) of Danos Ventures. “This process is cost-effective, proven, and unlike any other solution in the market.”

“Natrx is grateful to have Danos as a partner, and we’re excited about the launch of our first industrial-scale production facility in Louisiana. Having worked with Danos for years, we couldn’t imagine a better company to entrust our technology with,” said Natrx CEO Leonard Nelson.

Danos said that the storm-tested Cajun Coral delivers maximum protection while also supporting the growth of native oyster, coral, and fish populations. In addition to fabricating bioengineered modules, Danos offers a full range of coastal restoration support, including project management and field workforce.