MAN Compressors For Louisiana Hydrogen Complex

Air Products and Chemical Inc. (Air Products), a global provider of industrial gases, has awarded MAN Energy Solutions (MAN) an order for six compressor trains for use in an air-separation unit in its Clean Energy Complex in Ascension Parish, Louisiana. Upon completion in 2026, the facility will produce more than 750 MMscf/d (21.2 × 106 m3/d) of blue hydrogen. A portion of the blue hydrogen will be compressed and supplied to customers via Air Products’ extensive US Gulf Coast hydrogen pipeline network that stretches more than 700 miles (1126 km) from Galveston Bay, Texas, to New Orleans. Today, the pipeline network can supply customers with more than 1.6 Bscf/d (45.3 × 106 m3/d) from 25 production facilities, including blue hydrogen supplied from the Port Arthur, Texas, facility which has captured about 1 million tons (907,185 tonnes) of carbon dioxide annually since 2013. The balance of the blue hydrogen from the new Ascension Parish facility will be used to make blue ammonia that will be transported around the world and converted back to blue hydrogen for transportation and other markets.

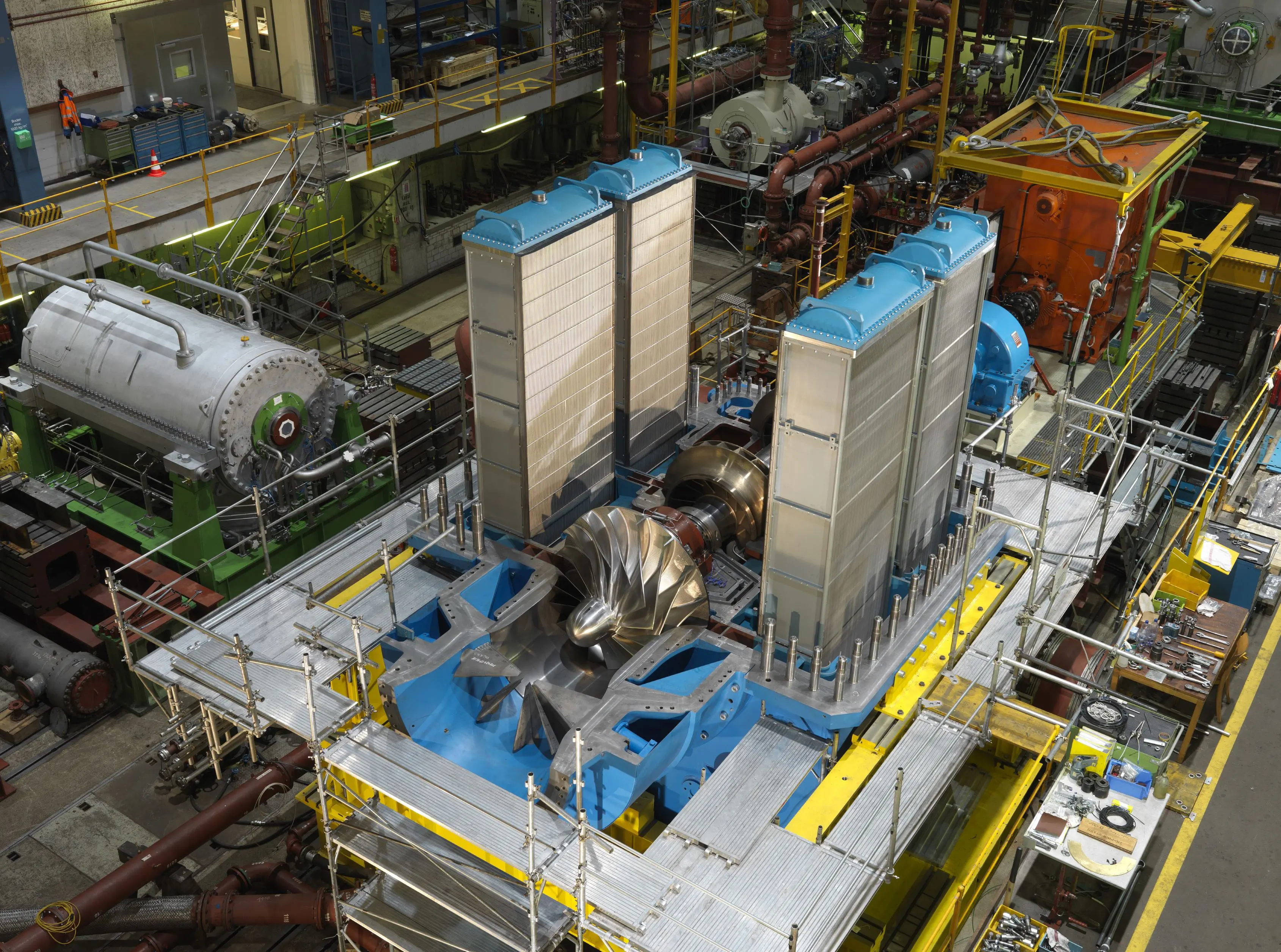

MAN’s compressor trains will be deployed at the core of Air Products’ air-separation unit where air will be separated into its primary constituents of oxygen and nitrogen. Both gases are needed to produce hydrogen and ammonia.

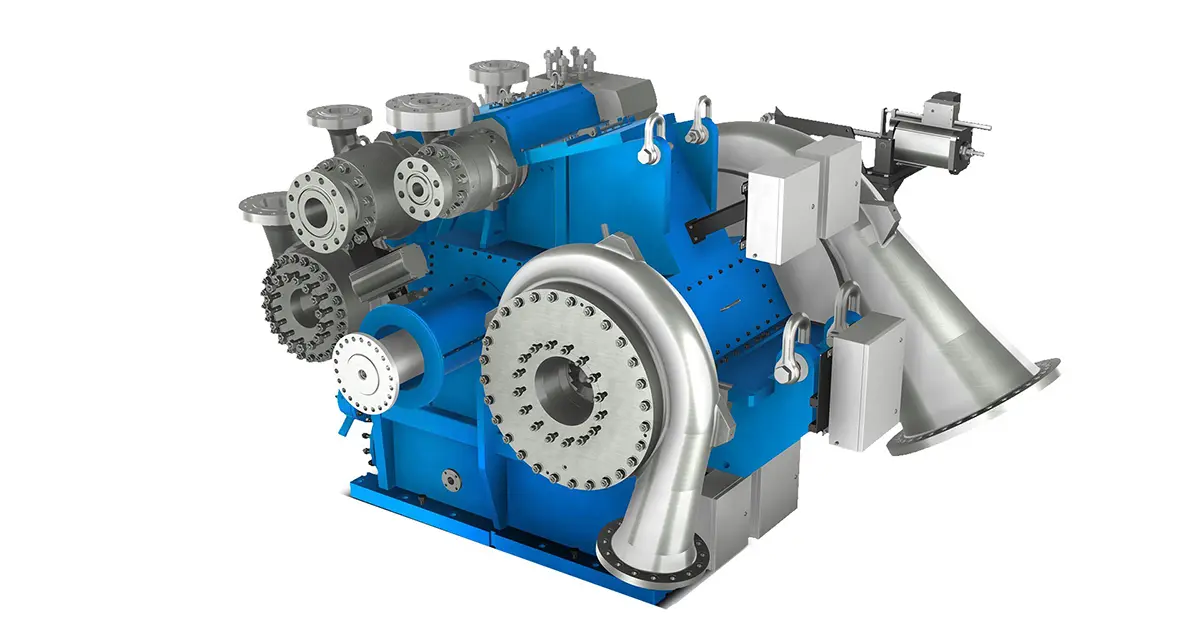

MAN’s scope of work for the energy complex comprises two main air-compressor trains, each equipped with a single-shaft RIKT 160-3 type compressor. It also includes two booster air-compressor trains, each with an integrally geared RG 63-6 type compressor; as well as two gaseous nitrogen compressor trains, each with an MAN integrally geared RG 45-5 type compressor. All the trains will be electrically driven.

The main air-compressor trains, the largest in MAN’s RIKT portfolio, have three centrifugal stages and deliver more than 600,000 Nm3/h of air. The booster compressors are integrally geared types and have six (air) and five (nitrogen) stages, all with external intercoolers.

“The technical features of MAN air-compressor trains make them ideal for air-separation applications; they help operators achieve maximum performance while reducing energy consumption and minimizing environmental impact,” said Zoran Paunovic, head of sales and project management for Air Separation at MAN. “We can provide two different types of compressors to meet the customer’s needs. The RIKT compressors feature an impeller design that increases energy efficiency while reducing wear and tear on the unit. This design improves the compressor’s overall performance and extends its service life, leading to greater reliability and lower maintenance costs, combined with a very compact design and small footprint. In contrast, the RG compressors are ideal for reaching different high-pressure demands by using different shaft speeds to run each impeller within the optimum efficiency point. In this way, energy consumption can be reduced while reaching maximum capacity.”

Air Products will build, own, and operate the US$4.5 billion megaproject. Approximately 95% of the carbon dioxide generated at the facility will be captured, compressed, and transported by pipeline to multiple inland sequestration sites located along a pipeline corridor extending 35 miles (56 km) to the east of the new production facility. More than 5 million tons (4.5 million tonnes) per year of carbon dioxide will be permanently sequestered in geologic pore space secured from the state of Louisiana approximately one mile beneath the surface.