A Marriage Of Technology

Carbon capture and storage (CCS) has become a popular method for reducing carbon emissions. In simple terms, the three-step process involves capturing the carbon dioxide (CO2) produced in power generation, oil and gas processing, and other industrial applications; transporting the captured CO2 via pipeline, ship, or tanker truck; and storing it deep underground. CCS requires complex machinery, and compression is a critical step in the process.

“CO2 is relatively easy to compress because it is a dense gas. This generates a lot of heat during compression, which requires it to have multiple stages of intercooling between the compression process,” said Klaus Brun, director of Research and Development at Elliott Group. “CO2 is transported in its super critical phase, meaning at a pressure and temperature where it behaves more like a liquid than a gas. At that point, really what you do is pump it. Ultimately, a compressor is needed to get the CO2 to the super critical state; above the super critical state, a pump is needed.”

According to Brun, for high-pressure ratio carbon sequestration CO2 applications, reciprocating, screw, multistage-centrifugal barrel, integrally geared centrifugal, and diaphragm compressors are used. “Since reciprocating, diaphragm, and screw compressors are severely flow limited, they cannot be practically used for large-scale carbon sequestration applications. On the other hand, centrifugal compressors tend to be non-ideal for applications when the process fluid is either a liquid or in the dense phase. These could either be barrel-style compressors or integrally geared compressors, which have advantages and disadvantages based on the application.

“One promising technology for large-scale CCS applications is a hybrid combination of a centrifugal compressor to compress the gas to slightly above its critical point, in series with a dense phase pump to reach the desired process discharge pressure,” continued Brun. “This combination of turbomachinery can be packaged with a driver, a single gearbox for the compressor, and direct drive for the pump.”

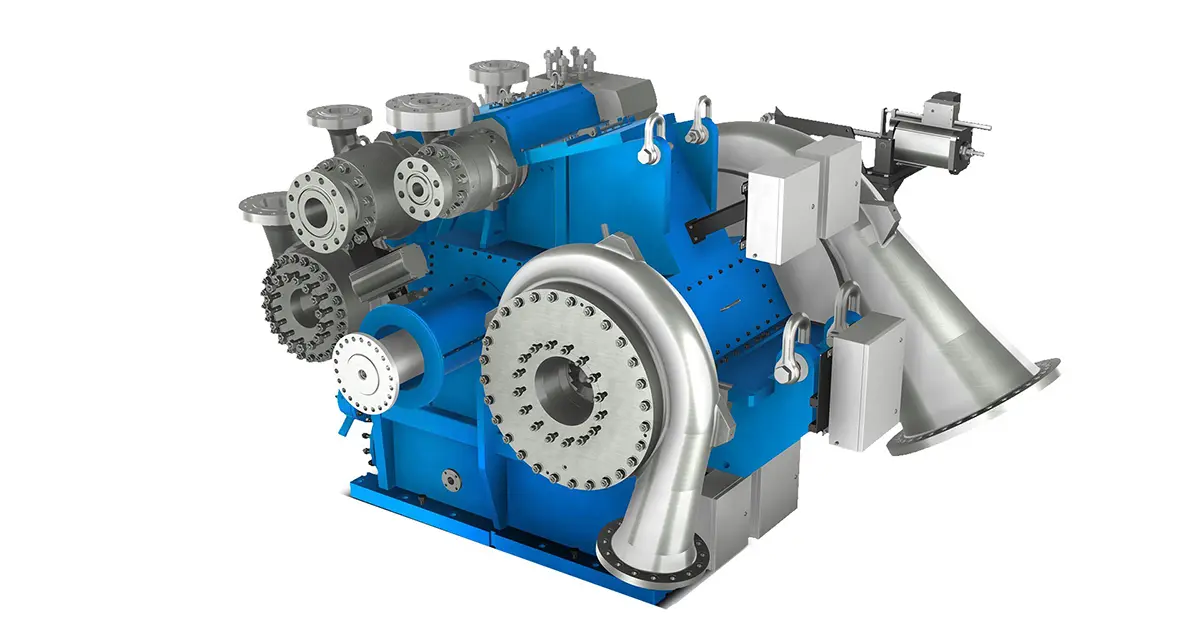

While low-pressure CO2 compressors and dense-phase pumps are proven technologies, a hybrid combination of the two is relatively unique. Combining its experience in CO2 compression with pump technology developed by parent company Ebara Corporation, Elliott Group has unveiled the CO2 Phase Hybrid Compressor Pump Solution (CO2 Phase).

“We use an Elliott compressor to compress the CO2 from 30 to 50 psi (2.06 to 3.44 bar) to about 1350 or 1450 psi (93.07 to 99.97 bar) in the compression process, and above that we use an Ebara pump,” said Brun. “We combine these two products to get the compression rate needed. This compressor/pump design is equipped to handle any project and/or equipment related to CO2 compression needs from atmospheric pressure to typical piping pressure of around 2200 psi (151.68 bar) and higher for sequestration requirements. Using both compressor and pump technology, this CO2 compression system can optimize equipment and minimize operating costs. It is ideal for CO2 pipelines and CO2 sequestration.”

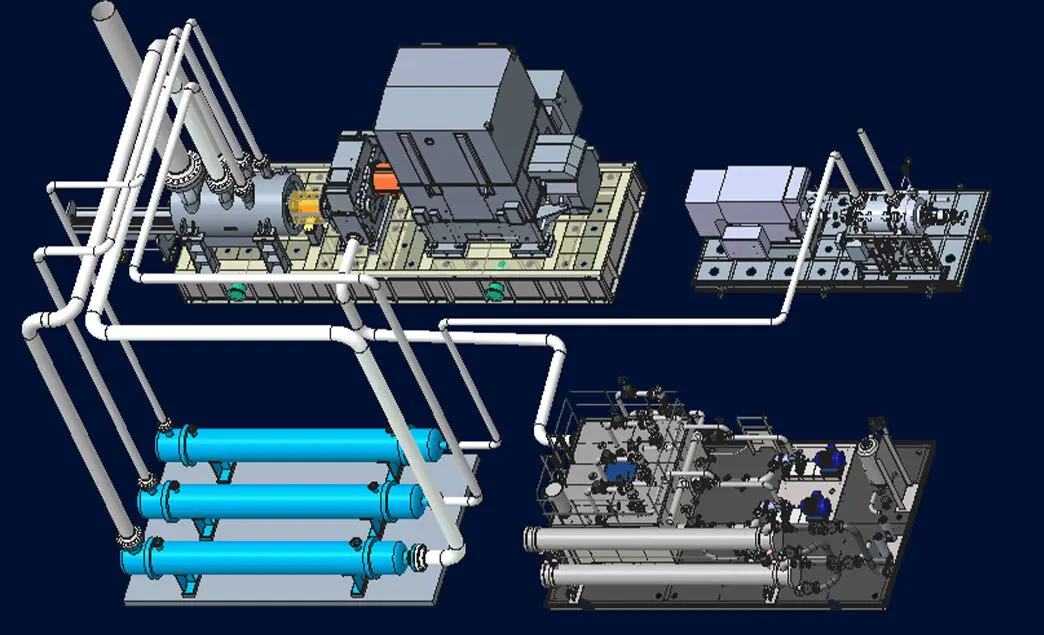

While each package configuration may vary slightly based on the customer’s specific conditions or needs. A typical CO2 Phase compressor package includes the compressor, pump, motor(s), gear, lube system, and buffer or seal system. Configurations are available with a double ISO-cooled compressor with a pump and two motors. This combination of turbomachinery can be packaged with a driver with a single gearbox for the compressor and a direct drive for the pump.

“We go from very high-volume flow rates on the suction side to very low-volume flow rates on the discharge side,” said Brun. “With the compressor, we managed to get a compression ratio from near atmospheric to 1350 or 1450 psi above the critical point of the gas in a single casing. The single casing has two stages of intercooling. There is a discharge cooler before the compressed CO2 goes into the pump, so in total, there are three stages of cooling, making the entire process very efficient.”

To simplify shipping, installation, and commissioning, the CO2 Phase uses a modular package design. “This is especially true for installations where there are generally no footprint limitations, and access for maintenance and repair is critical,” said Brun. “Several packaging options exist, and are specific to the application, location, maintenance strategy, and available utilities. In some cases, a more compact, single-lift module may be desired, whereas in cases where there are no footprint limitations, a larger, more distributed packaging design may be preferred.”

Brun sees growing opportunity for CO2 compression. “With the drive toward a low-carbon energy economy comes the need for added new compression of CO2. Further CO2 will be produced from power plant flue gas separation, cement plants, and other industrial processes, and it must be sequestered. This CO2 must be compressed from near atmospheric conditions to pipeline operating pressure, then transported in the pipeline, and finally compressed to geological formation storage pressures for long-term sequestration,” said Brun.

“Elliott’s CO2 Phase Hybrid Compressor Pump solution is proven, ready-now technology that addresses the CO2 compression market,” concluded Brun. “The technology allows for compression of CO2 from near atmospheric pressure to supercritical pressures followed by efficient pumping of the CO2 to the final required pressure.”