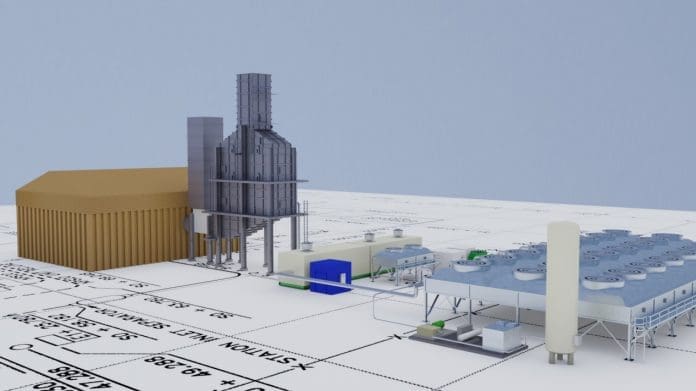

Siemens Energy (Siemens) has signed an agreement with Canada-based TC Energy Corporation (TC Energy) to commission a waste heat-to-power pilot installation in Alberta. The facility will capture waste heat from a gas-fired turbine operating at a pipeline compression station and convert it into emissions-free power. The electricity produced will be put back into the grid – resulting in estimated greenhouse gas reductions of 44,000 tons (39,916 tonnes) per year.

As part of the agreement with TC Energy, Siemens will build, own, and operate the facility, with the option for ownership to be transferred back to TC Energy at a later date.

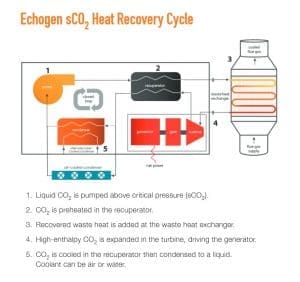

At the heart of the facility will be a heat recovery process designed by Siemens. The patented technology, licensed under Echogen Intellectual Property, is based on an advanced Rankine Cycle and uses supercritical carbon dioxide (sCO2) as the working fluid to convert waste heat into power. Because of its properties, sCO2 can interact more directly with the heat source than water/steam, eliminating the need for a secondary thermal loop, typically required in traditional waste heat recovery systems.

According to Siemens, by deploying sCO2-based waste heat recovery solutions, midstream operators can realize greater value than traditional alternatives based on Organic Rankine or steam cycles. Benefits include a 25% to 40% smaller footprint than steam-based systems, a 10% increase in compressor station efficiency, and the capability to produce emissions-free electricity.

The pilot project is supported by US$8 million in funding from Emissions Reduction Alberta’s (ERA) Industrial Efficiency Challenge. For more than 10 years, ERA has been investing the revenues from the carbon price paid by large final emitters to accelerate the development and adoption of innovative clean technology solutions. Since ERA was established in 2009, they have committed US$616 million toward 186 projects worth US$4.55 billion that are helping to reduce greenhouse gases, create competitive industries, and are leading to new business opportunities in Alberta. These projects are estimated to deliver cumulative reductions of 38.5 million tons (35 million tonnes) of CO₂e by 2030.

The new facility is expected to be commissioned in late 2022.

“The agreement with Siemens on this initiative exemplifies TC Energy’s long history of embracing innovation and leading-edge technology in its operations,” says Corey Hessen, senior vice-president, and president, power and storage at TC Energy. “We are committed to integrating sustainable energy solutions that reduce greenhouse gas emissions across our footprint and look forward to having this operational at one of our compressor stations.”

TC Energy is currently evaluating other compressor station sites to deploy the technology, with the potential to generate 300 MW of emissions-free power.

About sCO2

The sCO2 is stable, non-toxic, non-flammable, and exhibits favorable thermal-physical properties, including high latent heat and energy density, along with fluid stability. The compact, modular system can achieve high efficiencies over a wide temperature range. According to Siemens, it can be retrofitted with a wide variety of heat sources without disrupting existing plant operations. Additionally, the system does not require water, making it particularly advantageous for facilities in arid zones or regions subject to sub-freezing temperatures.

The waste heat-to-power pilot installation in Alberta will capture waste heat from a gas-fired turbine operating at a pipeline compression station and convert it into emissions-free power.