From Grey To Green

Neste’s plans to demonstrate production of green hydrogen at its Rotterdam refinery have entered the execution phase, with construction set to begin on the MULTIPLHY project. In development since early 2020, the MULTIPLHY project will install, integrate, and operate the world’s first high-temperature electrolyzer (HTE) system in multi-megawatt-scale (~2.4 MW) at Neste’s renewable products refinery in Rotterdam.

Headquartered in Espoo, Finland, Neste is a global producer of renewable diesel and sustainable aviation fuel refined from waste and residues, introducing renewable solutions to the polymers and chemicals industries. With operations in 14 countries, it produces, refines, and markets oil products, provides engineering services, and licenses production technologies.

In addition to Neste, the MULTIPLHY consortium partners include Sunfire, a developer of high-temperature electrolyzers and high-temperature fuel cells based on solid oxide cell technology; CEA, a French public research organization; Paul Wurth, an engineering company and technology provider; ENGIE, a global reference in low-carbon energy and services.

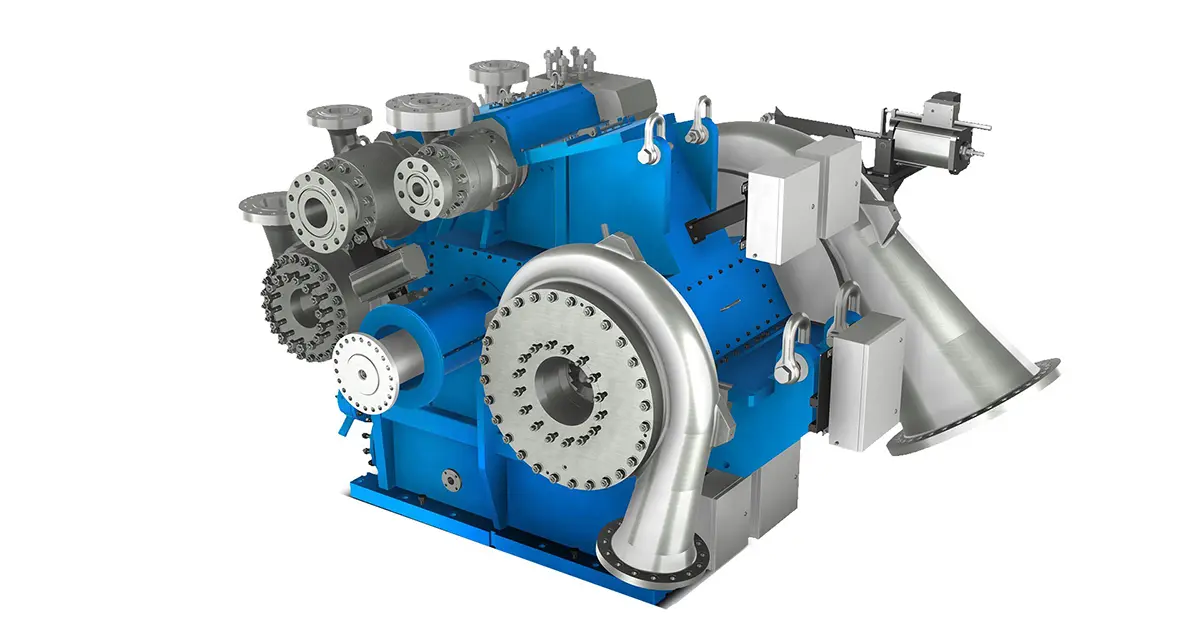

SIAD Macchine Impianti (SIAD MI) will provide the compressor that will be integrated into the hydrogen processing unit, which has been designed and manufactured by Paul Wurth. The compressor, developed by SIAD MI, is suitable for automatically managing hydrogen at low pressures (0 to 33 bar) and is designed to follow the variable operation of the electrolyzer.

When complete, the MULTIPLHY project will allow renewable hydrogen production (≥ 60 kg/h) to replace grey hydrogen for the refinery’s processes.

Demonstrating the high-temperature electrolyzer technology is an important step forward in the field of Power-to-X. In the scope of the project, Sunfire will supply the multi-megawatt electrolyzer based on solid oxide electrolysis cell (SOEC) technology, operating at high temperatures of 850°C. Due to the utilization of heat, the high temperature electrolyzer requires significantly less electricity to produce one kilogram of green hydrogen.

“We look forward to realizing the implementation and commissioning of our SOEC electrolyzer. Together with the strong MULTIPLHY consortium, we will demonstrate an innovative solution on how the refining industry can become more sustainable,” said Sunfire CEO Nils Aldag.

The project consortium led by CEA, as project coordinator, is part of the EU Horizon 2020 FCH2-JU program with an overall funding of EUR 6.9 million.

MULTIPLHY marks the first demonstration of an HTE in an industrial refining process with a nominal power input of 2.6 MW and a hydrogen production capacity of 60 kg/h reaching an electrical efficiency of up to 85% AC to LHV H2.

“As part of Neste’s growth strategy we continue to focus on innovation, in which renewable hydrogen and Power-to-X are two of our key development areas,” said Lars Peter Lindfors, senior vice president of innovation at Neste. “Demonstrating green hydrogen production at our Rotterdam refinery within the MULTIPLHY project is one of the initiatives enabling us to further drive the development of new sustainable technologies.”