Successful Hydrogen Test For GE Vernova

GE Vernova Validates 100% Hydrogen-Fueled Dry Low NOx Combustor Technology

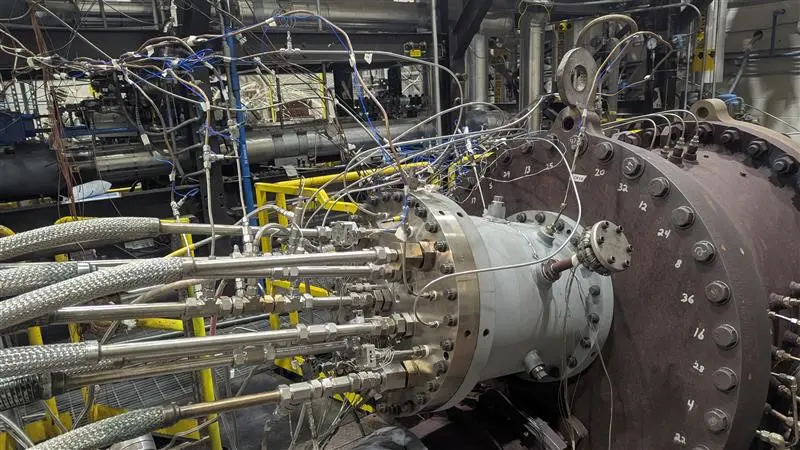

GE Vernova Inc. (GE Vernova) has completed the validation test for its advanced Dry Low NOx (DLN) hydrogen combustion technology for B- and E-class gas turbines. The test, conducted at GE Vernova’s Global Technology Center in Greenville, South Carolina, demonstrated successful operation on natural gas and hydrogen blends and on 100% hydrogen with dry emissions below 25 ppm NOx. GE Vernova currently plans to make the new DLN system available for new and existing B- and E- gas turbines as early as 2026.

“We are proud to celebrate this technological advancement aiming to enable the decarbonization of our B- and E-Class fleet across the word,” said Jeremee Wetherby, Carbon Solution leader, GE Vernova. “Developing a DLN combustion system able to burn 100% hydrogen safely and reliably is an engineering challenge. One of the ways hydrogen fuel differs from natural gas is that it burns much faster. Its flame speed is roughly eight times higher and presents risk of flashback. Through the test campaign, the GE Vernova team demonstrated very robust operation for the new DLN technology, without flash- back across a range of loads and fuel from pure natural gas to 100% hydrogen.”

Combustion dynamics or noise can be a challenge as well with hydrogen operation. According to GE Vernova, the prototype performed very well in that category with relatively low levels even when operating on pure hydrogen. Test results also indicate that the technology can deliver higher availability and longer maintenance intervals comparable to current DLN combustors operating on natural gas. This is of particular importance for industrial customers who depend on gas turbines to power their operations reliably.

A new micromixer-based fuel air pre-mixer is foundational to the prototype combustor capability. GE Vernova’s research on micromixer technology started in 2005 as part of collaboration with the US Department of Energy. Micromixer-based fuel premixers have been part of the product portfolio for over seven years notably on GE Vernova’s H Class gas turbine fleet. Recent research conducted at GE Vernova’s Advanced Research Center in New York and at the Global Technology Center in Greenville focused on improving micromixer and axial fuel staging for hydrogen capability. This research culminated with the construction of a full size 6B DLN combustor prototype and testing in full scale conditions (pressure, flow, temperature) in the combustion test facility in Greenville