Advancing Hydrogen-Fueled Gas Turbines

GE Vernova Aims To Have The First 100% Hydrogen-Fueled Aeroderivative Gas Turbine In Commercial Operation

By Drew Robb

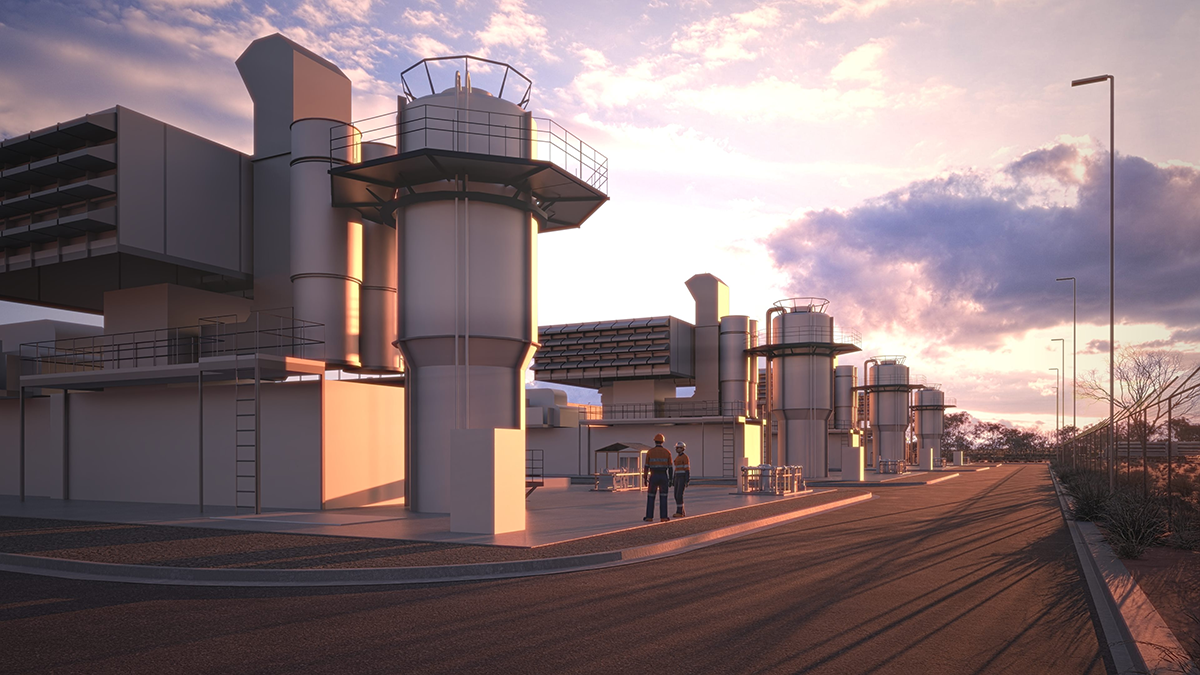

GE Vernova’s LM6000 gas turbines, which lie at the heart of its LM6000VELOX package, are destined for the Whyalla hydrogen power plant in the Upper Spencer Gulf, South Australia. When these machines are deployed, the company expects that they will quickly become the first ever aeroderivative gas turbines to operate on 100% hydrogen at commercial scale. No CO2 will be produced at the gas turbine exhausts during operation when fueled only with renewable hydrogen. The order for these units came from ATCO Australia. It is for four LM6000VELOXs that are scheduled for commissioning in early 2026.

The VELOX Package

The design of the LM6000VELOX aeroderivative package is based on the success of GE Vernova’s LM2500XPRESS. With most assembly taking place in the factory, the LM2500XPRESS is all about speed and simplicity. It comes pre-packaged in 10 modules for easy installation. It features 27 electrical interconnects vs. 130+ for a traditional plant, as well as minimal mechanical interconnects. Module systems flushing is completed at the factory, so customers don’t need to flush on-site. For customers who need power fast, the LM2500XPRESS can be installed in about 14 days.

The engineers behind the LM6000VELOX package followed similar principles.

“The LM6000VELOX PC was inspired by the successful LM2500XPRESS,” said Olamide Ogunduyile, GE Vernova’s Gas Power, aero technical sales executive. “The LM6000VELOX is 95% factory assembled into simplified modules for fast and easy site installation and commissioning. It is a 51 to 57 MW gas turbine package solution that offers greater than 99% start and operational reliability and over 98% availability. Its five-minute fast start allows operators to differentiate their dispatch capability while a simple two-spool design results in lower overall maintenance costs.”

The LM6000VELOX package contains the LM6000 PC, which offers from 46.6 to 51.1 MW, depending on whether it uses the SPRINT version to produce an additional power boost. Its heat rate is 8533 Btu/kWh (lower heating value), and it operates at 40% efficiency in a simple cycle configuration (up to 52.2% as a combined cycle). It can provide 30 MW of power per minute as it ramps up and can startup from cold condition in five minutes. It can also be turned down to as low as 25% of full load if desired. The LM6000VELOX is available in both simple and combined cycle configurations, as either a Dry Low Emissions (DLE) or Singular Annular Combustor (SAC; water injected) combustor, and for both 50 and 60 Hertz markets.

The VELOX package was developed at GE Vernova’s Manufacturing Center in Veresegyház, Hungary. Features include enhanced modularity including a package-mounted air filter; a base-mounted generator and gearbox to reduce foundation labor; a prepackaged roof skid that is shipped as one piece; reduced lube oil flushing including pre-flushing; and an improved drive train alignment procedure that cuts alignment time in half. Its ability to burn up to 100% hydrogen has further enhanced its attractiveness in the marketplace.

“GE Vernova has been investing over the years in research and development to advance the capabilities of its combustion systems to burn higher blends of hydrogen,” said Eric Gray, chief executive officer of GE Vernova’s Gas Power business.

Beyond the LM6000, GE Vernova has over 120 gas turbines that have the capacity to operate or currently are operating on fuels that contain hydrogen. To date, these machines have produced more than 530 Terawatt-hours of electricity.

Initial Orders

The first order for the LM6000VELOX package was from the Tennessee Valley Authority (TVA), which chose the Dry Low Emissions (DLE) option for its dual fuel capability, high cyclic life, and fast start time. TVA has now deployed 10 of these units at its Johnsonville Aeroderivative Plant in Middle, Tennessee.

“What’s unique about this product is its dispatchability. It is capable of numerous starts and stops throughout the day,” said Tom Agro, new unit sales director, GE Gas Power. He noted that LM6000VELOX units can each put 50 MW on the grid within five minutes, which adds up to 500 MW when needed.

The latest order for LM6000 VELOX packages is for the Whyalla site in Australia, which will soon include one of the world’s largest hydrogen production and storage plants. As well as becoming a new source of flexible power, the Whyalla hydrogen power plant aims provide grid stability for homes and businesses around the state by utilizing excess renewable energy generated from large-scale wind and solar farms to provide a consistent output of supply. The stored hydrogen will power the four LM6000VELOX units.

The Whyalla hydrogen power plant is expected to deliver a combined capacity of up to 200 MW. At times when wind and solar are either not available or unable to meet full demand, the facility will pick up the slack by burning hydrogen to run the turbines. This hydrogen is produced via large electrolyzers that are powered by excess renewable energy. Thus, this hydrogen earns the “green hydrogen” label as it is entirely produced without the use of fossil fuels.

South Australia’s Hydrogen Jobs Plan

South Australia’s goal to generate more electricity from renewable sources has produced an unexpected result: More wind and solar energy are being generated than there is demand from industrial and residential users. While this may be a positive from an environmental standpoint, it has created occasional intermittency issues.

Accordingly, the South Australian government has established Hydrogen Power SA to offer grid firming services via several new hydrogen electrolyzers, including at the Whyalla hydrogen power facility. This plant will house one of the world’s largest hydrogen production and storage plants. Up to 100 tonnes of hydrogen can be stored at a time to fuel the power station, and to provide industry with hydrogen to decarbonize their operations by making green steel, green cement, or green ammonia. This amount of hydrogen has been calculated as the amount needed for industrial offtakes as well as power generation firming needs. Construction of the Whyalla facility is scheduled to begin early in 2025, with the plant expected to begin operating in 2026.

The state is working with transmission company ElectraNet to upgrade the connectivity of Whyalla with the South Australian energy grid. Stronger transmission lines are required to move excess renewable energy from the grid to the hydrogen electrolyzers and to transmit up to 200 MW of hydrogen-produced renewable electricity from the LM6000VELOX units back onto the grid when wind and solar generation are lacking.

Natural gas will be used during the commissioning phase of the turbines and as well as during turbine start-up and shutdown. The intention is to transition to 100% renewable hydrogen operations and to have natural gas available as needed.