MAN Compressors For Indonesia CCUS Project

MAN Energy Solutions (MAN) will supply three integrally geared compressors for bp’s enhanced gas recovery (EGR) and carbon capture, utilization, and storage (CCUS) project at the Tangguh liquefied natural gas (LNG) plant in Papua Barat, Indonesia. This effort is part of Tangguh’s integrated Project UCC, which will extend the gas feed to Tangguh’s 3-train LNG operations while at the same time, the EGR/CCUS will significantly reduce Tangguh LNG carbon footprint via carbon dioxide (CO2) sequestration

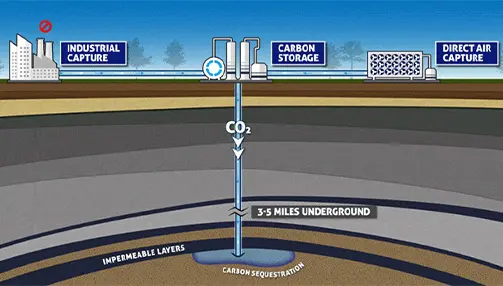

Tangguh LNG EGR/CCUS will have three injection wells, one offshore injection platform, one offshore CO2 pipeline, and onshore facilities for CO2 removal, processing, and compression.

Tangguh LNG EGR/CCUS will separate the reservoir CO2 from produced gas and reinjecting it back to the Vorwata gas field for sequestration and enhanced gas recovery. The total emissions reduction is up to 30 MT of CO2 equivalent by 2035 while up to 300 Bcf (8.4 x 109 m3) of natural gas is produced as additional LNG cargoes for the domestic and international markets.

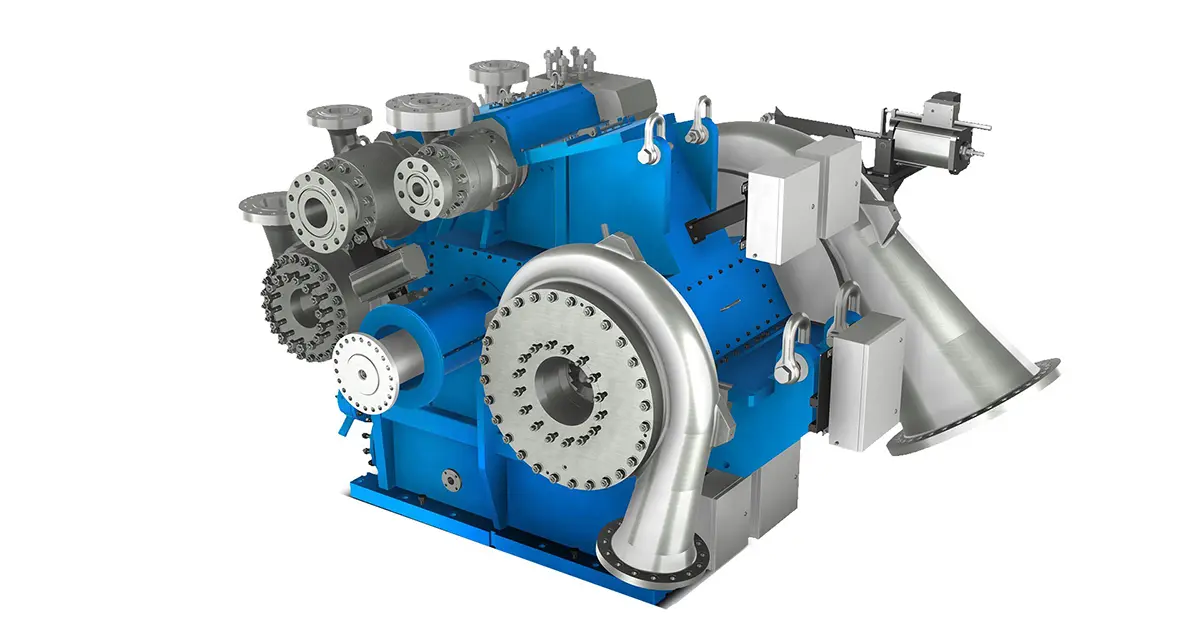

MAN’s scope of supply includes three multi-shaft integrally geared CO2 compressors, type RG90-8, each equipped with an electric motor and variable frequency drive starter, oil system, coolers, and control cabinet. The solution also includes a dynamic process simulation, allowing the compressor system to operate at its fullest potential in terms of process efficiency. MAN’s compressor trains will be located at an onshore facility.

The Tangguh project utilizes a modular compressor design specifically developed for CCUS applications, enabling a tailored approach to meet market demands.

“Pre-designed compressor modules allow us to adapt our engineering more quickly and effectively to the specific project needs,” said Lars Rosenow, project manager sales at MAN. “This modular approach not only helps reduce [capital expenditures] CAPEX and [operating expenditures] OPEX but also ensures high operational efficiency. Additionally, it simplifies project implementation by reducing production and testing times and streamlining on-site installation.”