Toyota’s Hydrogen Hilux Project Enters Demonstration Phase

Toyota’s hydrogen fuel cell Hilux pick-up has moved into its next and final phase. Since the unveiling of the first prototype vehicle in September 2023, Toyota and its consortium partners, supported by UK Government funding, have reached an intensive evaluation and demonstration stage. Toyota believes that the latest landmark in this joint development project further demonstrates the broad scope of Toyota’s multi-path strategy toward carbon neutrality, applying different powertrain solutions — hybrid electric, plug-in hybrid electric, battery electric, fuel cell electric and e-fuels — to suit different user needs and local infrastructure.

A total of 10 fuel cell Hilux prototypes have now been built at the Toyota Motor Manufacturing UK (TMUK) facility in Derby, England. Five vehicles are undergoing field testing to assess safety, performance, functionality, and durability, generating test drive data in real-world situations. Five further units are engaged in customer and media demonstrations, including two at the forthcoming Olympic and Paralympic Games Paris 2024.

Along with Toyota’s 30 years of research and development into hydrogen fuel cells, know-how from the Hilux project will contribute to the next generation of fuel cell technology, which could offer longer lifecycles, increased driving range for vehicles, and significantly reduced costs.

Toyota expects Europe to be one of the largest hydrogen fuel cell markets by 2030, with steady growth in mobility and power generation applications. In December 2023, Toyota Motor Europe (TME) announced the Hydrogen Factory Europe, representing Toyota’s coordinated approach to the commercialization of this technology, from development and production to sales and aftersales.

The fuel cell Hilux prototype project is an important steppingstone for Toyota to further develop hydrogen technology and stimulate a wider roll-out of hydrogen eco-systems and infrastructure across Europe.

Vehicle Profile

Since its initial launch in 1968, the Hilux has been at the North Pole, Icelandic volcanoes, and the Antarctic continent. Externally, the fuel cell Hilux retains the same dimensions and appearance as the latest Hilux. In extra-cab format, it is 17.47 ft. (5325 mm) long, 6.09 ft. (1855 mm wide), and 5.93 ft. (1810 mm) tall.

Power is delivered using core elements from the Toyota Mirai, which was introduced as the world’s first mass-produced hydrogen fuel cell sedan in 2015.

The fuel cell Hilux has an expected driving range of up to 373 miles (600 km) — further than might be achieved with a battery electric system. Meanwhile, thanks to hydrogen’s light weight, a higher payload and towing capability can be achieved compared to other zero-emissions alternatives.

Hydrogen is stored in three high-pressure fuel tanks, each containing 5.7 lb. (2.6 kg) for a total system capacity of 17.2 lb. (7.8 kg). The tanks are mounted within the ladder frame chassis.

The polymer electrolyte fuel cell stack contains 330 cells and is mounted above the front axle. The fuel cell Hilux is rear-wheel drive via an e-motor on the rear axle which delivers 134 kW (180 hp) of maximum power and 300 Nm maximum torque. When driving, the fuel cell produces no tailpipe emissions, only pure water.

A Lithium-ion hybrid battery stores the electricity produced on-board by the fuel cell and is positioned in the rear load deck, above the hydrogen tanks. This avoids any loss of cabin space.

Project Overview

Starting with a feasibility study in early 2022 to demonstrate the advantages of hydrogen via a representative prototype vehicle, the hydrogen fuel cell Hilux prototype project has moved forward toward its concluding phase.

The feasibility study, undertaken by TMUK and TME, enabled subsequent funding from the UK Government through the Advanced Propulsion Centre, a non-profit organization supporting the development of cleaner technologies and new mobility concepts.

A design and development program ran from July 2022 to January 2023, alongside consortium partners Ricardo, ETL, D2H Advanced Technologies, Thatcham Research, and with additional support from Toyota.

Parts manufacturing, including chassis frame welding, took place between February and May 2023, prior to prototype construction, which followed Toyota Production System principles in a dedicated area within the TMUK facility. Ricardo supported preparations for the prototype build, carrying out design and development tasks and confirming the complete manufacturing process in parallel with teams at TMUK.

Prototype construction took place between June and July 2023 and the first vehicle was completed in just three weeks. A further nine prototypes were assembled prior to a thorough evaluation phase from July to December last year, including test rig and track testing.

Those 10 prototypes are now undergoing field testing alongside customer engagement activities, which will conclude the final phase of this research and demonstration project for the fuel cell Hilux.

Hydrogen Solutions

Since the start of its hydrogen fuel cell development in 1992, Toyota has expanded its knowledge of the technology and encouraged its adoption across a wide variety of different mobility uses, with more than 20 hydrogen partnerships currently active in Europe.

These include a five-year trial with hydrogen-powered VDL Energy Systems trucks to decarbonize Toyota’s logistics operations and stimulate the further development of sustainable hydrogen infrastructure across Europe.

Since July 2021, Toyota cobrands fuel cell buses with its CaetanoBus partner while French clean mobility company GCK uses Toyota’s fuel cell modules to convert 10 diesel coaches to zero tailpipe emissions vehicles and provide transportation to more than 5000 visitors during the Olympic and Paralympic Games Paris 2024.

A partnership with Corvus in Norway has realized one of the safest and most advanced marine fuel cell systems available. Furthermore, Toyota worked closely with Energy Observer to create the first hydrogen-powered, zero-emissions boat to be self-sufficient in energy.

Toyota fuel cells are also used for non-mobility applications, such as the modular fuel cells that form the basis of Toyota partner EODev’s GEH2 generators. In May 2021, those generators illuminated the Eifel Tower in Paris with green, sustainable light.

Toyota’s Hydrogen Fuel Cell Development

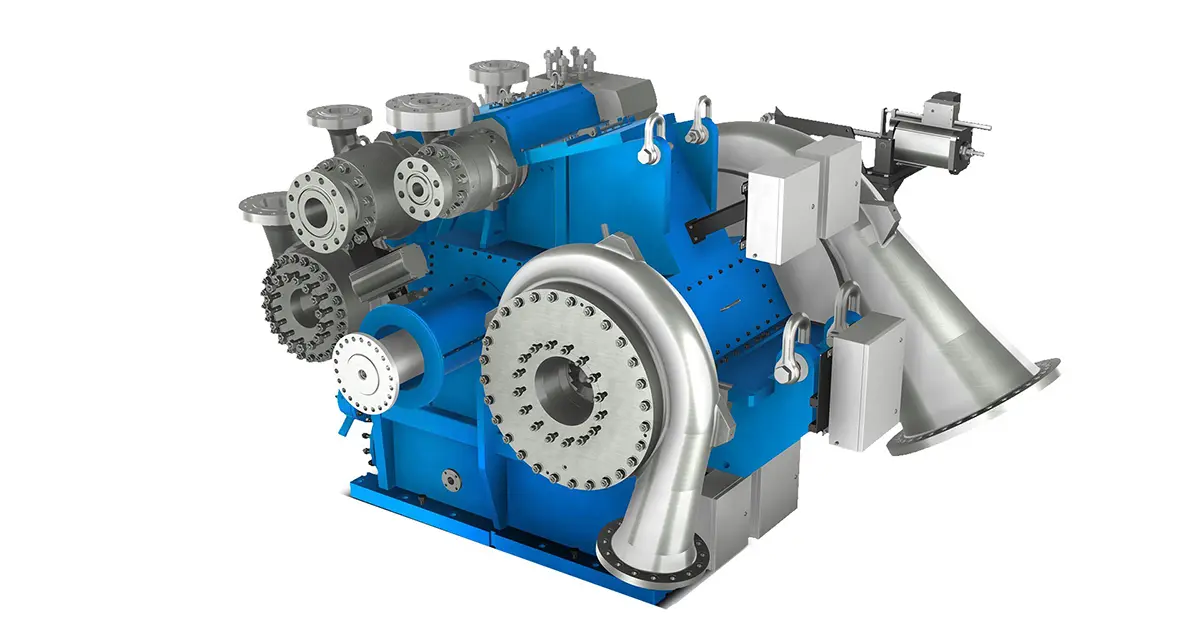

Building on its extensive experience, Toyota is developing its next generation of hydrogen fuel cells, expected to deliver industry leading performance through longer lifecycles and reduced costs. To expand the potential of hydrogen beyond cars, Toyota has repackaged its fuel cells into a compact modular form. The main components, the fuel cell stack and components that handle air supply, hydrogen supply, cooling, and power control, are integrated in a compact shape that Toyota says can be easily adapted into a variety of products and applications. The modules are available in a box or a flat, rectangular format to allow greater flexibility and easier adaptation into new applications.

These fuel cell modules are assembled locally in Europe, at TME’s research and development in Belgium, which houses an assembly line combining advanced technologies with high-quality assembly. The Hydrogen Factory Europe operation will produce an increasing number of fuel cell systems and is closely connected with Toyota’s other hydrogen operations to achieve global reach and service.

A key element of Toyota’s plan for an expansion in hydrogen usage is the new, third-generation fuel cell technology currently under development, with sales scheduled for 2026 to 2027. These units will deliver a higher power density and an expected 20% increase in driving range. Toyota said that these technical advances and increased production volumes can help to reduce costs by more than a third. Further research is also looking at the potential of scalable fuel cell stacks with different power outputs and design of fuel tanks with complex shapes, compatible with different size vehicles.