Ebara Elliott Compressors For Sustainable Aviation Fuel Project

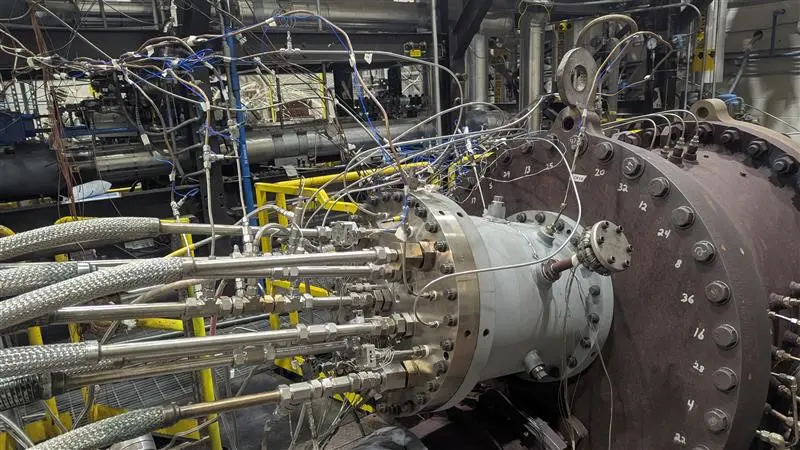

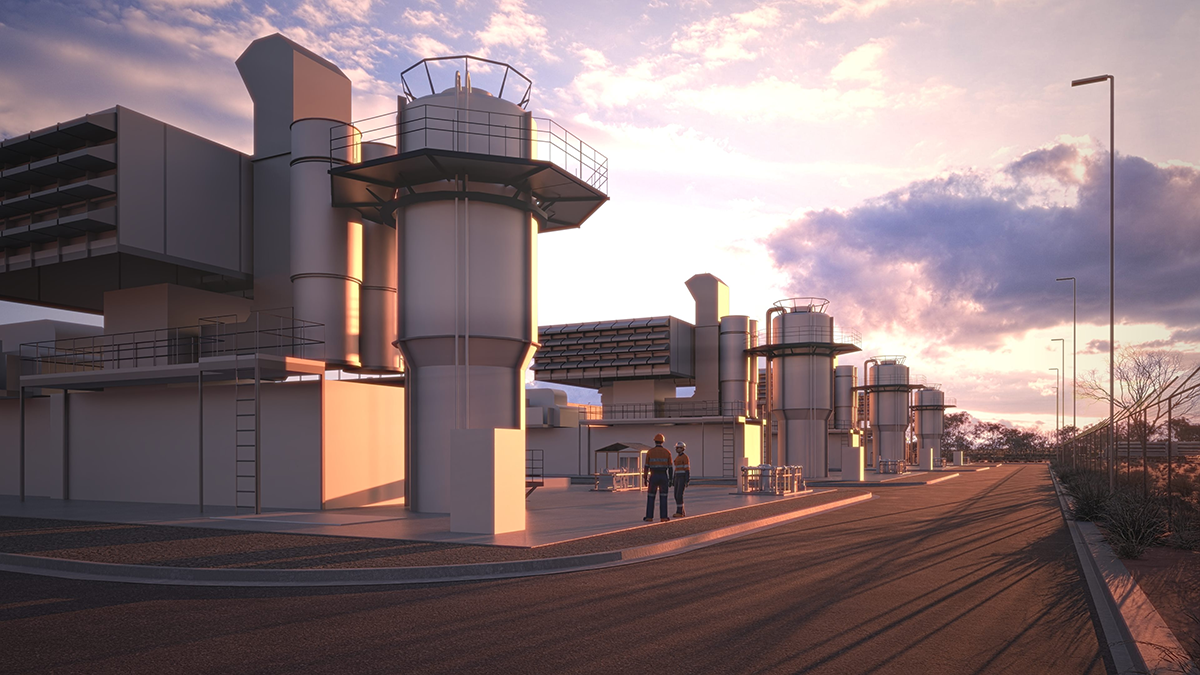

Ebara Elliott Energy, formerly Elliott Group, will provide a motor-driven recycle compressor with a variable frequency drive for the Sustainable Fuel Development Project (SFDP) in Bangkok. The order was placed by TTCL Public Co. Ltd. The SFDP will be operated by BSGF Co. Ltd., a joint venture between Bangchak Corp. Public Co. Ltd., BBGI Public Co. Ltd., and Thanachok Oil Light Co. Ltd.

Using 100% used cooking oil, the sustainable aviation fuel (SAF) production plant will have an initial daily capacity of 1 million liters. According to BSGF Co. Ltd., the aviation industry can immediately use SAF without affecting engine performance, and the production of SAF will help reduce the industry’s greenhouse gas emissions by approximately 80,000 tons of carbon dioxide equivalent annually (compared to present emission levels). This reduction equals 20 round-trip flights per year between Chicago and Tokyo for 300 passengers.

SAF production utilizing used cooking oil is a common process with existing refinery applications such as hydro-treatment, according to Ebara Elliott Energy’s Director of Sustainability Business Development HongPing Zhang.

“Ebara Elliott Energy has extensive experience and expertise with hydrogen-rich gas centrifugal compressors,” said Zhang. “We understand that SAF will play an important role in the decarbonization of the aviation industry, and we are excited to be a part of this innovative project that will contribute to reducing greenhouse gas emissions in Thailand.”