SLB announced an agreement to combine its carbon capture business with Aker Carbon Capture to support accelerated industrial decarbonization at scale. Bringing together complementary technology portfolios, process design expertise, and an established project delivery platform, the combination will leverage Aker Carbon Capture’s commercial carbon capture product offering and SLB’s new technology developments and industrialization capability. The companies believe it will create a vehicle for accelerating the introduction of disruptive early-stage technology into the global market on a commercial platform. Following the transaction, SLB will own 80% of the combined business and Aker Carbon Capture will own 20%.

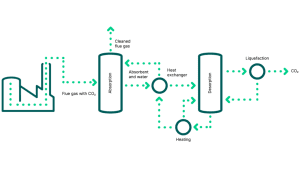

The International Energy Agency (IEA) sees carbon capture, utilization, and sequestration (CCUS) playing a critical role in the net-zero transition — estimating that more than 1 gigaton of carbon dioxide (CO2) per year will need to be captured by 2030, scaling up to more than 6 gigatons by 2050. The ramp up will demand untold amounts of CO2 gas compression so the gas can be transported through pipelines and then used in industrial processes, enhanced oil recovery, or stored in geologic formations. According to a report by the Department of Energy, “Geologic carbon sequestration, also called carbon storage, involves storing CO2 deep underground in porous rock formations. In this approach, the CO2 is compressed to the supercritical phase, where it behaves like a liquid. Next, it is injected into porous rock formations deep under the ground, where it becomes physically trapped in the pore spaces, dissolves in the fluid within the formations, and eventually reacts to form stable minerals.”

“For CCUS to have the expected impact on supporting global net-zero ambitions, it will need to scale up 100 to 200 times in less than three decades,” said Olivier Le Peuch, chief executive officer of SLB. “Crucial to this scale-up is the ability to lower capture costs, which often represent as much as 50% to 70% of the total spend of a CCUS project. We are excited to create this business with Aker Carbon Capture to accelerate the deployment of carbon capture technologies that will shift the economics of carbon capture across high-emitting industrial sectors.”

Aker Carbon Capture’s technology has more than 60,000 operating hours, has been tested on 11 different flue gases, has eight years of solvent development, and has been selected on several large-scale projects. Aker Carbon Capture believes it has superior health, safety, and environmental characteristics thanks to a system that achieves minimum emissions, is non-toxic and biodegradable, and has minimum liquid waste and corrosion.

SLB will pay US$380 million to purchase 80% of Aker Carbon Capture Holding AS, which holds the business of Aker Carbon Capture, and will contribute the SLB carbon capture business to the combined entity. SLB may also make additional payments of up to US$130 million over the next three years based on the performance of the business.

The transaction is subject to regulatory approvals and is expected to close by the end of Q2 2024.

SLB Carbon Capture Project Updates

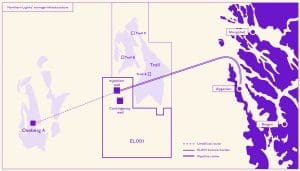

SLB’s New Energy segment is centered around carbon capture. In its Q4 2023 earnings release, the company said that the Northern Lights Joint Venture and SLB have signed a memorandum of understanding with Microsoft to optimize integrated cloud-based workflows for the operation of Northern Lights, one of the first CO2 transport and storage providers for cross-border carbon capture and storage (CCS). According to SLB, the collaboration will contribute to the development of scalable and cost-efficient digital solutions. In the initial phases of the collaboration, SLB will extend its digital CCS workflows and numerical simulation systems on Delfi, which was deployed to streamline the subsurface workflows of Northern Lights in 2022. In December 2022, the project received seven onshore tanks for temporary CO2 storage. Phase 1 installations are scheduled to come on stream later this year, with the ability to handle 1.5 MTPA of CO2 per year. The North Lights Joint Venture’s ambition is to extend the project to 5 MTPA by 2026.

In the United Arab Emirates, Sharjah National Oil Corporation awarded SLB a CCS consultancy project with the objective to inject CO2 and other gases into mature onshore Sharjah gas fields. SLB will leverage its storage site evaluation solution, which incorporates measurement, monitoring, and verification planning, and will apply SLB technical knowledge and experience in reservoir management and subsurface technologies to evaluate capacity, injectivity, and containment. The project will assess the carbon storage potential for reliability, economics, and sustainability, and provide consultation on the injection and monitoring strategy.

In Japan, INPEX and JOGMEC completed a CCUS pilot test in the Minami-aga depleted oil and gas field with SLB technology providing support for two injection wells and a short-term injection test. In the drilling phase, SLB said that Sonic Scanner acoustic scanning platform and MDT modular formation dynamics testing data were instrumental in containment evaluation. SLB deployed its WellWatcher permanent reservoir monitoring systems for the project. For the injection test, SLB designed and executed CO2 pumping and delivered integrated services for coiled tubing, surface testing, and cased-hole wireline logging. The Pulsar multifunction spectroscopy service was employed for near-wellbore CO2 monitoring. Before and after CO2 injection, an Optiq fiber-optic solutions workflow was used for temperature and acoustic monitoring.

SLB’s project updates and continued investment illustrates the growth potential of CCUS for oilfield services and equipment providers.