Turboden S.p.A. (Turboden), a Mitsubishi Heavy Industries Group company, has been selected by Strathcona Resources Ltd. (Strathcona) to design and produce North America’s largest single-shaft turbine organic Rankine cycle (ORC) system with a gross nameplate capacity of up to 19 MW.

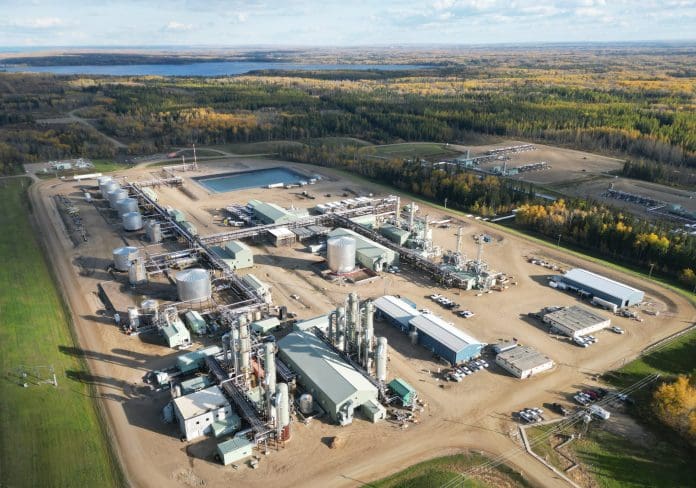

The ORC system, which is planned to be implemented at Strathcona’s Orion thermal oil facility located near Cold Lake, Alberta, Canada, will use waste heat recovery to generate carbon-free electricity, offsetting approximately 80% of the facility’s existing grid-power consumption.

Implementing ORC technology at steam assisted gravity drainage (SAGD) operations, like Orion, will allow Strathcona to capture previously lost low-grade thermal heat at approximately 302°F (150°C) and convert it to emissions-free electricity that can be used to help self-power operations and reduce need to draw from the local power grid. Low-grade thermal heat from the Orion facility was previously released through aerial coolers.

SAGD involves introducing steam into the subsurface oil sands deposit to heat the bitumen in the sand, allowing it to flow by gravity to horizontal wells placed at the base of the reservoir.

Strathcona’s ORC implementation is slated for completion in the first half of 2025. The project will be constructed within the facility’s existing operational footprint and is estimated to result in approximately 815,710 tons (740,000 tonnes) of greenhouse gas emissions reductions over the project lifetime.

“We see tremendous value in implementing Turboden’s ORC system at our Orion facility,” said Rob Morgan, president and chief executive officer of Strathcona. Strathcona is a Canadian oil and gas producer with operations focused on thermal oil, enhanced oil recovery, and liquids-rich natural gas. “The technology will convert a waste energy stream from our SAGD operation into usable electricity, lowering power supply costs and reducing the carbon footprint of our operation — demonstrating once again how technology can be applied to improve both the economic and environmental performance of our industry.”