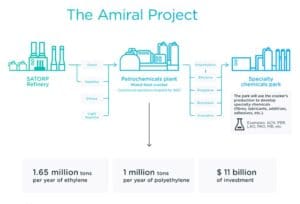

TotalEnergies and the Saudi Arabian Oil Company (Aramco) are working together to develop the Amiral project, a new refining and petrochemicals platform in Saudi Arabia. Both partners took their final investment decision in December 2022 to build a petrochemical complex integrated with the Satorp refinery. Operational since 2014, Satorp is comprised of two distillate hydrocrackers to convert heavy petroleum fractions into lighter, ultra-low-sulfur products; a fluid catalytic cracking unit that produces a wide variety of products, including very light hydrocarbons such as propylene and liquefied petroleum gas; and a coking unit used to convert heavy fractions into light petroleum products and coke.

The Amiral project is being developed and will be operated by the Satorp joint venture owned by Aramco (62.5%) and TotalEnergies (37.5%). The project represents an investment of US$11 billion and is scheduled to begin commercial operation in 2027.

Upon completion, the Amiral complex will convert feedstock produced directly by the Satorp refinery, such as its off-gases and naphtha, as well as ethane and light naphtha supplied by Aramco. The Amiral complex will eventually provide feedstock to other specialty chemical and petrochemical plants that will be located in the Jubail Industrial Area.

The Amiral petrochemical complex will be comprised of a mixed feed cracker capable of processing different grades of low-cost feedstocks and producing 1.65 million tons (1.5 million tonnes) of ethylene per year; two polyethylene units leveraging advanced dual-loop technology, each with a capacity of 500,000 tons (453,592 tonnes) per year; a butadiene extraction unit; and other associated derivatives units.

The mixed feed cracker will be the first in the region to be integrated with a refinery. The facility will use naphtha and refinery off-gases from Satorp refinery, and ethane and natural gasoline as feedstock.

Special attention is being paid to its carbon intensity. As part of the Amiral project, some of the hydrogen coproduced by the steam cracker will replace the methane used as a fuel in the Satorp refinery’s furnaces.

In June, Aramco and TotalEnergies awarded engineering, procurement, and construction (EPC) contracts for the project, marking the start of construction work.

Hyundai Engineering & Construction Co. Ltd. (HDEC) was awarded a contract for two EPC packages. Valued at US$5 billion, one package involves installing a mixed-feed cracker to produce an additional 1818 tons (1650 tonnes) per annum of ethylene and related industrial gases. The second package relates to installation of facilities that supply utilities such as electricity and water to plants, and functions as interconnecting systems that support main packages within the facilities. HDEC will execute detailed design, procurement, construction, commissioning, and start-up activities.

Maire Tecnimont S.p.A. was awarded two turn-key EPC contracts for the project. The overall value of the contracts is approximately US$2 billion. The first contract includes a butadiene extraction unit, an olefin extraction unit, a methyl tert-butyl ether unit, a butadiene selective hydrogenation unit, a 2nd-stage pygas hydrogenation unit, and a benzene and toluene extraction unit. The second contract includes two polyethylene units and the relevant product logistic facilities.

Sinopec Engineering Saudi Co. Ltd., a Sinopec company, was awarded an EPC contract valued at US$720 million, which is currently the largest refining and chemical engineering general contracting project independently undertaken by China’s Sinopec in the Saudi Arabian region. The main scope of work includes the design, procurement, and construction of the project tank farm and integration with the Satorp refinery.

Other EPC contract awards include Mohammed Ali Al-Suwailem Trading and Contracting Co. for industrial support facilities, Gulf Consolidated Contractors Co. for transfer pipelines, Mofarreh Marzouq Al Harbi and Partners Co. Ltd for site preparation, and Mobarak M. AlSalomi and Partners for temporary construction facilities.