ABEL Energy has selected Johnson Matthey and SunGas Renewables as suppliers for two of the key technologies to be deployed for the Bell Bay Powerfuels project (Bell Bay) in Northern Tasmania. An Australian green hydrogen and methanol project developer, ABEL Energy has been working closely with SunGas Renewables and Johnson Matthey on the design and optimization studies to fully integrate their technologies into the proposed facility.

Upon completion in 2027, Bell Bay is scheduled to produce 330,693 tons (300,000 tonnes) of green methanol per year. This amount is three times Australia’s current methanol consumption and the shipping-fuel equivalent to removing 595,248 tons (540,000 tonnes) of fossil fuel carbon dioxide from the atmosphere.

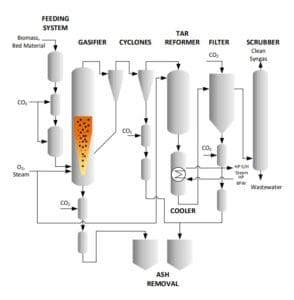

The project will combine green hydrogen from a 240-MW water electrolysis plant with synthesis gas from a biomass gasifier to produce green methanol. The production process will use 100% renewable power from hydro and new wind production assets, fresh water from major river systems, and biomass residues recovered from existing Tasmanian plantation forestry operations.

SunGas Renewables will provide its SunGas System 1000, a renewable syngas generation unit. SunGas developed its System 1000 product line for renewable synthesis gas production needed for manufacturing hydrogen and renewable biofuels such as gasoline, diesel, sustainable aviation fuel, and marine shipping fuels.

Johnson Matthey has optimized the design of the methanol synthesis loop and combined it with a methanol synthesis catalyst. The addition of green hydrogen increases methanol production and leads to increased carbon utilization efficiency, the company said.

The project is located in Tasmania’s Bell Bay within an existing industrial precinct, on the site of a decommissioned oil-fired power station. This strategic location supports deep water port infrastructure, a high-capacity grid connection, and large quantities of biomass residues from established sustainable plantation fiber processing and export industry.

The surge in demand for green methanol follows a host of new orders by container shipping companies for new ships to be fueled by this sustainable clean-burning fuel. In July, A.P. Moller – Maersk (Maersk) placed an order for six mid-sized container vessels – all having dual-fuel engines able to operate on green methanol. Yangzijiang Shipbuilding Group will build the six 9000 TEU (twenty-foot equivalent unit) vessels, which will be delivered in 2026 and 2027.