SunGas Renewables Inc. has announced the formation of Beaver Lake Renewable Energy LLC (BLRE), which will construct a new green methanol production facility in Central Louisiana. A wholly owned subsidiary of SunGas Renewables, the new BLRE facility is expected to generate nearly 441,000 tons (400,000 tonnes) of green methanol per year.

Green methanol produced by BLRE is expected to be used to fuel A.P. Moller – Maersk’s (Maersk’s) fleet of methanol-powered container vessels and will use wood fiber from local forests. The methanol will have a negative carbon intensity through sequestration of nearly a million tons per year of carbon dioxide produced by the project, which will be executed by Denbury Carbon Solutions.

SunGas Renewables anticipates BLRE will invest approximately US$2 billion to construct the project at the former International Paper facility in Rapides Parish. The BLRE facility is expected to begin construction in late 2024 with commercial operations commencing in 2027.

“Using biomass from sustainably managed forestry along with carbon capture allows our project to generate green marine shipping fuel while simultaneously removing carbon from the atmosphere. This new low-carbon marine fuel facility also helps strengthen communities and create sustainable economies right here in Rapides Parish, Louisiana,” said Robert Rigdon, chief executive officer of SunGas Renewables.

In late 2022, SunGas Renewables announced a strategic green methanol partnership with Maersk, a Denmark-based container shipping company, to produce green methanol from multiple facilities around the country. Maersk is using green methanol to fuel its new and growing fleet of methanol-powered container vessels. The BLRE project is SunGas Renewable’s first facility to produce green methanol for Maersk.

SunGas facilities use the company’s System 1000 platform to convert residues from the forestry and wood products industries into green methanol. The SunGas system can process many sources of woody biomass including stumps, bark, slash, and pellets, as well as agricultural, construction, and demolition wastes.

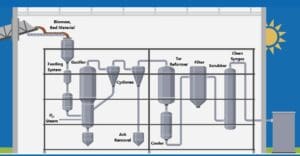

The process begins by transferring wood chips by conveyor from a wood yard where they have been processed and dried to specification and are received by a series of lock hoppers. The standard SunGas system is designed to process 1000 tons (907 tonnes) per day of wood chips. The wood chips move through the lock hoppers and are fed into the gasifier where they react with a mixture of oxygen and steam at approximately 1600°F (871°C).

Inside the gasifier, a specific amount of oxygen and steam is injected to ensure the wood chips are completely converted into gases. The syngas moves from the gasifier into the tar reformer, where the tar and oils from the gasification of the wood are removed to produce a clean syngas, which is mostly made up of carbon monoxide, carbon dioxide, and hydrogen.

The syngas moves into a syngas cooler and then scrubber. The syngas then progresses through a series of process equipment that transform the syngas into biofuels or biochemicals, depending on the product being produced for a specific project.

“Maersk is excited to be partnering with SunGas Renewables, which is pioneering a truly large-scale pathway to green methanol with its BLRE facility,” said Emma Mazhari, head of energy markets at Maersk. “This is helping Maersk deliver valuable services to our customers and is aligned with our aim to reach net-zero greenhouse gas emissions by 2040. Together, as pioneers in the field, SunGas and Maersk are driving a much-needed transition in a heavy pollution industry. We hope that work can be accelerated further in the years to come.”