Wales-based Compact Syngas Solutions (CSS) has won US$5.07 million from the Department for Energy Security and Net Zero (DESNZ) to test a method of capturing carbon from its clean fuel process. The funding will help CSS build a full-scale rig to show that water can be used to separate and store carbon dioxide (CO2) during the process. This has previously been achieved with amines, a potentially harmful compound derived from ammonia. Full-scale rollout could see 50 UK modules built to convert waste to liquid fuel that could capture around 32,000 tons (29,000 tonnes) of CO2 per year. CSS previously won a first round of funding for US$314,350.

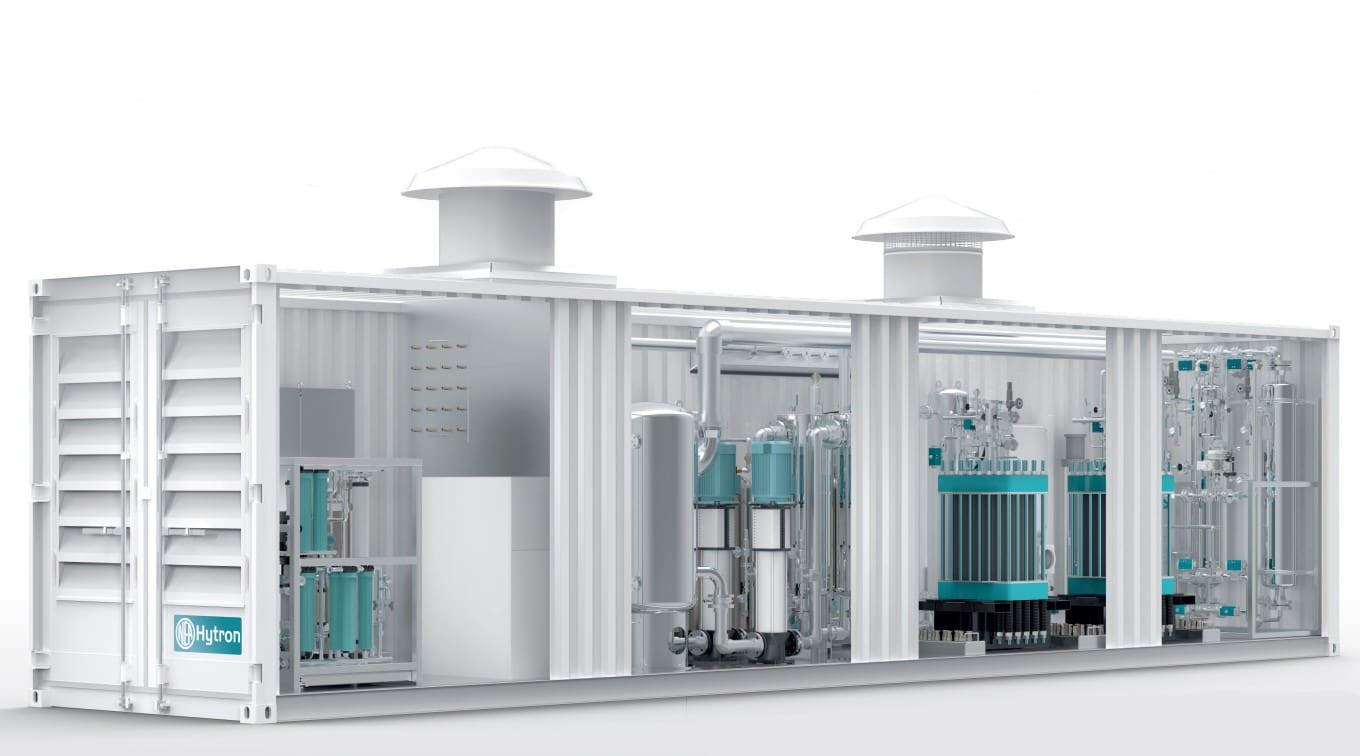

CSS has developed an advanced gasification process that generates hydrogen gas from waste products, including biomass like waste wood and other selected non-recyclable materials. This waste is often sent to landfill, where it decomposes and emits harmful gases including CO2 and methane into the atmosphere. The technology harnesses this waste by converting it into syngas, a valuable gas that can be used to produce hydrogen for use as a cleaner fuel. Removing the CO2 reduces the carbon footprint of the hydrogen produced and makes the process more efficient. The syngas, once separated from the hydrogen, is also used in a gas engine that generates energy to power the process and export surplus to the grid, maximizing outputs from the system.

During the project, the rig will run continuously for 1000 hours, reliability testing the technology and getting it ready for commercialization. Every day, a single module will produce 1653 lb. (750 kg) of hydrogen — enough to fuel a fleet of hydrogen gas vehicles (HGVs) — and capture 3527 lb. (1600 kg) of CO2.

CSS plans to build more than 50 hydrogen modules at around 15 sites, ranging from a single module to six per site, offering the flexibility to suit local demand. These 50 modules will annually produce 12,125 tons (11,000 tonnes) of hydrogen and capture 21,967 tons (29,000 tonnes) of CO2.

The technology will be key to helping the United Kingdom reach its Net Zero 2050 target. The production of low-carbon hydrogen from waste materials stops it reaching landfill and creates a fuel that has no greenhouse gas byproducts. Hydrogen has many uses in transport and industry.

“Winning a second round of funding is an incredible achievement for the team,” said Paul Willacy, managing director of Compact Syngas Solutions. “We are delighted that we can now scale up technology into a commercial-scale demo plant, and we are actively looking for further investment to support rollout in the next couple of years. Capturing and storing the carbon from our gasification process and the hydrogen we produce will support the drive to net zero and lower the environmental impact of producing this green fuel at scale. Hydrogen has a very low environmental impact, but this project will help deal efficiently with the CO2 that emerges during its production.”