Siemens Energy Compressors For Large-Scale Direct Air Capture Plant

Siemens Energy compressors will be used at Occidental’s first large-scale direct air capture (DAC) plant in Ector County, Texas. 1PointFive, a subsidiary of Occidental, is developing the project, located in the Permian Basin. The two compressor packages will enable the plant to capture up to 551,000 tons (500,000 tonnes) of carbon dioxide (CO2) per year when fully operational. Detailed engineering and site construction began in Q3 2022. The plant is anticipated to complete commissioning and begin to capture carbon in late 2024. It will be commercially operational in mid-2025.

1PointFive partnered with Carbon Engineering to commercialize and deploy DAC technology at scale. DAC is a technology that removes CO2 from the atmosphere to provide a practical decarbonization solution. Dozens of high-powered fans pull air into the facility, where it is absorbed into a chemical solution of potassium hydroxide and water, which bonds to the CO2. This bonding happens as the potassium hydroxide flows across a highly engineered polyvinyl chloride (PVC) packing system designed to increase the surface area and amount of CO2 captured.

Once the liquid solution reaches the unit’s outlet, the process of concentrating the captured CO2 begins. First, the solution is pumped into a piece of equipment called a pellet reactor. Calcium hydroxide is added, forming small pellets of calcium carbonate that hold the captured carbon. The pellet slurry is pumped into a centrifuge where the pellets are separated from the refreshed potassium hydroxide. The pellets are then dried while the potassium hydroxide liquid is filtered and recycled back to the air contactors to capture more CO2. From the centrifuge, the calcium carbonate pellets are moved to a calciner, where they are exposed to high temperatures and converted into calcium oxide and CO2. The captured CO2 is sent off to be compressed and either stored or used.

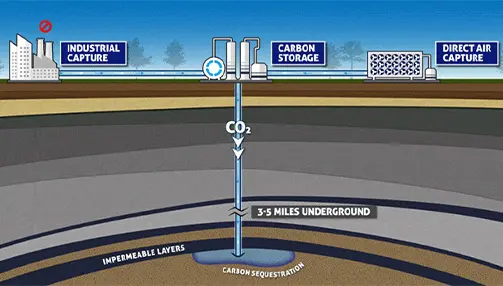

The calcium oxide pellets are recycled back into the process. They are first sent to a slaker, where, mixed with water, calcium hydroxide is formed and ready to go back into the pellet reactor where it will be used again to create new calcium carbonate pellets. With the CO2 captured, separated, purified, and compressed, it can be stored permanently deep underground or used as a feedstock for new products such as cement, plastics, or low-carbon fuels.

Siemens Energy will supply a motor-driven STC-GV(40-5) 13,000-hp (9698‑kW), fully modular, wet gas compressor package and a motor-driven STC-GV(2-6-H), 8500‑hp (6341‑kW), dry gas compressor for the DAC plant. The equipment will compress the captured CO2 for additional processing and pressurize the final product into a pipeline for injection into underground reservoirs.

The compressors will be manufactured and tested at the Siemens Energy facility in Duisburg, Germany, and packaged and assembled in Houston. “The intent is to execute as much work as possible in the factory before shipping to the field to ensure a smooth installation and commissioning phase to support Occidental’s online date,” said Patrice Laporte, vice president of Sales Compression, Americas for Siemens Energy. “The current design supports a shortened installation and commissioning duration for the compressors as compared to typical projects. Siemens Energy has been building integrally geared compressors for more than 50 years, so we have a wide range of experiences when it comes to different process conditions and the required design considerations. While a facility of this scale is the first of its kind, CO2 compression using these compressors is not. There are some unique features to this project, but the overall design considerations use proven technology that has been developed over years of experience.”

“Siemens Energy is proud to support Occidental in the first industrial-scale DAC project with our CO2 compressor packages,” said Laporte. “Taking CO2 from the atmosphere to either sequester it or reinject it into a well to achieve negative emissions in an oil and gas process has never been so exciting.”