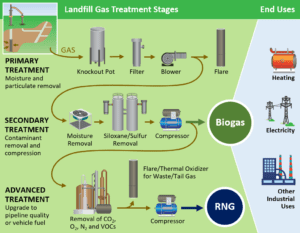

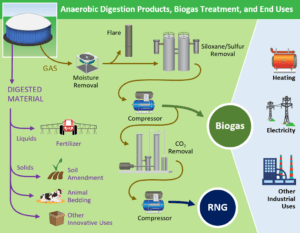

Biogas, now commonly referred to as renewable natural gas (RNG), is taking the US energy sector by storm due to its economic and environmental benefits. Municipal solid waste (MSW), wastewater, yard and crop wastes, food waste, and manure are all feedstocks that can be used to make RNG. MSW and wastewater typically feed into landfills, while yard and crop waste, food waste, and manure are processed through anaerobic digesters. However, these organic sources of biogas only contain 45% to 65% methane. By removing moisture, particulates, contaminants, and other gases such as carbon dioxide (CO2), oxygen, nitrogen, and volatile organic compounds (VOCs), the methane content is increased to a pipeline-quality concentration typically greater than 90% methane.

The process of treating landfill gas versus anaerobic digestion is a bit different (see Figure 1 and Figure 2). However, both processes involve multiple compression stages that are essential for creating pipeline-quality gas. Over the last decade, RNG has transitioned from speculation to one of the fastest growing industries in the energy sector. In January, Market Growth Reports published a 96-page paper that estimated the value of the US RNG market to be US$5.31 billion in 2021. The report forecasted that the US RNG industry will grow at a compound annual growth rate of 42.1% to reach a staggering US$62.11 billion by 2028 — increasing by more than 10-fold in less than a decade. This growth represents a unique opportunity for the gas compression industry to diversify revenue streams, grow profits, and achieve environmental targets.

The Path Toward 150 Anaerobic Digesters

Vanguard Renewables (Vanguard) is one of the major players in the RNG space that is contributing to the industry’s breakneck growth rate. “Simply put, Vanguard Renewables takes inedible food and beverage waste from the manufacturing sector and repurposes it with cow manure to create RNG,” said Neil Smith, CEO of Vanguard Renewables. “We are working to decarbonize supply chains by building, owning, and operating anaerobic digester facilities.”

In July 2022, a fund managed by BlackRock Real Assets acquired Vanguard from Vision Ridge Partners. BlackRock Real Assets will partner with Vanguard’s management team to build on the company’s track record and drive its next phase of growth. “The recent deal with BlackRock Real Assets has accelerated the rapid expansion of our projects nationwide,” said Smith. “We aim to have 150 digesters nationally by 2026 to generate enough energy to power hundreds of thousands of homes. Vanguard wanted a partner who believed in our ‘why’ and our purpose-driven mission. BlackRock Real Assets was committed to our vision of creating a network of digesters to help lead our country toward decarbonization. We needed a partner with capital willing to deploy US$2 billion in the next five years, and as a global leader in ESG initiatives and investments, BlackRock was the perfect fit.”

In addition to using the capital from BlackRock Real Assets to grow its digester portfolio, Vanguard is also quadrupling its workforce and expanding its company structure. “To reach our ambitious goals, we needed to grow the team in all divisions,” said Smith. “In 2022, we added more than 150 new members to the team, bringing the company total to more than 200 employees. And in 2023, we plan to continue hiring team members to accommodate the breadth of additional projects and work to find innovative solutions to improve its organics-to-renewable energy solutions.”

Humble Beginnings

With more than 200 employees and billions of dollars at its disposal, it’s hard to imagine that it was only 2014 when Vanguard Renewables was founded to revolutionize how the food and beverage industry views inedible waste from manufacturing by providing an alternative to landfills or harmful incinerators. “Greenhouse gas [GHG] emissions from inedible food waste and on-farm emissions are two significant climate crisis challenges,” said Smith. “However, these challenges are also the easiest to address. The company began by purchasing two operational facilities and quickly expanded to developing, owning, and operating anaerobic digesters on dairy farms across New England. When I joined the company in October 2021, I began accelerating the nationwide growth of our anaerobic digestion facilities. Today, we have eight projects under construction, six projects in development, and we operate 10 anaerobic digesters; six are in New England, three in Colorado, and one in Georgia.”

In addition to its anaerobic digester facilities, Vanguard owns and operates an Organics Receiving Area (ORA) in the Northeast. The site decontaminates expired goods, off-spec batches, or unsafe-to-eat food and beverage products. The extracted food is transported and recycled at a New England-based anaerobic digester, where it is combined with manure and converted into renewable energy. “As the company continues to grow, we are committed to adding ORAs nationwide alongside our anaerobic digester sites,” said Smith. “We have two facilities in Nevada that will be coming online this year and are expanding the scope of our work to look at new technologies and other synergistic business opportunities.”

Since its inception, Vanguard has recycled more than 650,000 tons (589,670 tonnes) of food waste and 250,000 tons (226,796 tonnes) of manure, mitigated emissions equivalent to more than 540,000 tons (489,880 tonnes) of CO2 (comparable to taking more than 119,000 cars off the road for one year), generated more than 86,000 MWh of renewable electricity (equal to powering more than 7500 homes for one year), and has generated more than 145,000 MMBtu of RNG (equivalent to fueling 418 buses for one year). Vanguard said it has also produced enough liquid fertilizer to sustainably fertilize more than 33,000 farm acres (13,355 ha) at its co-digestion sites alone, with additional methane emissions mitigation impacts from its manure-only facilities.

The Processes And Benefits Of Anaerobic Digestion

“Anaerobic digesters are large tanks or lagoons with attached gas-capturing mechanisms that harness biogas, composed of methane and CO2, expelled from decomposing cow manure with or without food and beverage waste,” said Smith. “Our two farm-based anaerobic digestion platforms create RNG that is then upgraded and cleaned of impurities to create pipeline-ready RNG. Hosting a facility minimizes on-farm methane emissions by recycling farm manure. A standard manure-only waste-to-energy project consists of a cluster of two to four farms and 10,000 to 30,000 dairy cows. A typical farm in our co-digestion program has 350 to 1500 milking head and approximately 1800 acres [728 ha] of cropland. Vanguard’s two platforms also create additional benefits for our farm partners, including bedding for the farmer’s herd that is rich in their cows’ biometrics and a nutrient-dense and low-carbon fertilizer. Each is a byproduct of the anaerobic digestion process. Due to supply chain issues and the rising costs of traditional fertilizers, these benefits save our farm partners thousands of dollars each year depending on the farm size.”

Vanguard is the owner and operator of the largest anaerobic digester in the Northeast, the Goodrich Family Dairy Farm in Salisbury, Vermont. The facility converts food waste and manure into RNG. The process starts at the facility’s 264,000-gallon (999,349 liter) hydrolyzer tank. “The food waste comes in the form of liquid and slurry, and gets deposited and pumped in through hoses, and we also accept more solid material that comes in through the solids hatch,” said Billy Connelly, new markets and national accounts manager for Vanguard Renewables. “There are two deck-mounted agitators, and those push the food waste material around. The residency time for the food waste is about five days before it then gets pumped from the hydrolyzer into the anaerobic digester, where it gets mixed with the manure to generate methane that becomes RNG.”

The anaerobic digester consists of two, 1 million-gallon (3.79 million-liter) digester tanks. “The manure and food waste get combined in the digester with the gut flora from the cows,” said Connelly. “It consumes that material and generates methane, which is a very potent gas that gets captured in the head space in these membranes, and that is the RNG that’ll be refined and then sent into the pipeline and down the line to the customers.”

The farm has an onsite combined heat and power system. “This 800-kW system generates enough power for the entire facility,” said Connelly. “The heating system generates enough heat to keep the hydrolyzer tank and all the material in it, as well as the digesters, at between 100°F and 102°F [37.8°C and 38.9°C], which is the optimal temperature for the methanogens. Methanogens are microbiology that generates the methane.”

The manure separator portion of the operation filters the liquid and the manure. “The liquid goes in one direction to our anaerobic digester, and the solids get separated out and used for animal bedding,” said Connelly. “And this is a more natural form of animal bedding. It’s not synthetic and it’s not sand, so the cows love it. And when the cows love it, the farmers love it. You have happy cows; you have happy farmers.”

The farm also has the only phosphorous removal system in the state of Vermont. “The digestive material gets pumped through a trommel screen, which sources and separates out contaminants,” said Connelly. “Then the material gets pumped over to this side, to a dissolved air flotation system. There’s a polymer that gets fed in and mixes with the dissolved air, and that pushes the phosphorous material to the surface. The foamy material then gets skimmed off by these skimmers and conveyed out to the other side of that wall into a closed container. The effluent flows from the phosphorous removal system into two 2.5 million-gallon [9.46 million-liter] effluent storage tanks, where it’s stored for use by the farmer. They take it and apply a low-carbon, high-strength fertilizer material to their crop fields in accordance with their nutrient management plan, and they’re regenerative agricultural practices.”

The final step in the gas upgrader. “The biogas from the digester gets fed into the gas upgrader, where we remove contaminants and upgrade the gas to pipeline quality, about 99% or better, pure methane,” said Connelly. “That gas then gets pumped through Vermont gas pipelines to customers down the line, including Middlebury College, and some RNG is also available to other Vermont Gas customers.”

Industry Opportunities

As rapid as the growth has been for Vanguard and the rest of the US RNG industry, it has been a drop in the bucket compared to what Europe and other regions have built. “When Vanguard launched nearly 10 years ago, anaerobic digesters in the United States were few and far between,” said Smith. “However, this technology has been deployed in the European Union for almost three decades, and the United States needed to catch up in its adoption of this technology. One of the significant challenges is the nascency of the industry in the United States, where there needs to be more national awareness about anaerobic digester technology and the benefits of RNG. There is not an extensive network of anaerobic digesters in the United States. Currently, the US has approximately 316 on-farm anaerobic digesters producing biogas throughout the 50 states compared to the European Union, which has more than 10,000 anaerobic digester sites. However, the desire to develop anaerobic digesters is increasing with national, state, and municipal renewable energy implementation and GHG reduction goals. Vanguard is providing a solution to one of the most significant challenges facing our planet — climate change.”

Challenges from Vanguard’s early projects have provided the crucial experience needed to refine the company’s process so it can acquire and build better projects. “I like to think of our facilities there as our learning laboratory, which has helped inform our new projects as we have begun moving into new markets — remaining true to our core mission of servicing America’s dairy farmers and providing food waste recycling solutions to manufacturers, grocery stores, and other food and beverage businesses that benefit people and the planet,” said Smith. “Our first projects in Massachusetts converted biogas into renewable electricity. While renewable electricity from biogas is effective, we always look for innovative and more efficient solutions and have transitioned all our ongoing projects to RNG. Over the last five to 10 years, the push for renewable energy and sustainable solutions to combat climate change has increased, especially following the signing of the Paris Agreement in 2015. Local, state, and federal legislation promoting renewable energy has further helped to make clean energy cost competitive compared to fossil fuel alternatives.”

In addition to the Paris Agreement, the recently passed Infrastructure Investment and Jobs Act and the Inflation Reduction Act (IRA) are proving an additional tailwind for the RNG industry. “The IRA includes incentives for climate-related emissions reductions projects and assists the advancement of new projects by expanding and introducing tax credits for biogas technology,” said Smith. “These new tax credits promote additional growth in anaerobic digesters projects across the United States. Another IRA provision that will benefit Vanguard Renewables and its customers is the money allocated to the Rural Energy for America Program that encourages the construction of renewable energy in rural or agricultural locations. Our manure-only digester projects are all located in rural and agriculturally dense areas of the United States. By promoting the expansion of anaerobic digesters and energy from biogas, food manufacturers and other companies with emissions goals will have expanded infrastructure to support them on their sustainability journeys. Additionally, Vanguard provides opportunities for companies to purchase the RNG created at our sites to help in their decarbonization efforts. The benefits of both these legislative pieces are vital touchpoints in creating a green economy, and they will allow us to continue to be part of the solution to the ongoing climate crisis.”

RNG’s Growing Role In The Methane Mitigation Toolbox

Roughly one-third of all energy consumed in the United States comes from natural gas. Despite its growth over the last decade, RNG still makes up less than 1% of US natural gas consumption. As investment and federal support for lower-carbon alternatives continues to grow and companies look for short-term viable solutions, RNG could begin to take market share from other forms of renewable energy. “With the onset of solar and wind power over the last three decades, RNG is another tool — and a better one — in our methane mitigation toolbox,” said Smith. “As a renewable energy source, RNG has risen to the forefront of the sustainability conversation in recent years for its ability to mitigate methane emissions. This harmful GHG is 25 times more potent than CO2 over 100 years. I believe RNG to be carbon-negative [depending on details of use and GHG accounting methods] because it is derived from the decomposition of organic products that would otherwise decay, releasing methane in one of our nation’s landfills — which many are set to close by 2030. Further, the mitigation of methane through the anaerobic digestion process makes RNG a better GHG-reduction profile than solar or wind per megawatt. The potential benefits RNG provides Vanguard’s farmers, food and beverage partners, and the planet has informed our decision to continue the accelerated growth of our manure-only and co-digestion projects across the country.”

By using anaerobic digesters and microorganisms that naturally occur in manure to digest the food waste and convert sugars, fats, and other compounds into biogas, Vanguard’s process has been shown to capture a uniquely high portion of GHG emissions. “Sequestering organic waste captures as much as 95% of the potential GHG emissions if the food and beverage waste was sent to a landfill or the farm manure was field applied,” said Smith. “The extracted biogas is cleaned and upgraded to produce RNG for heating and cooling or CNG for vehicles. The remaining liquid digestate is a low-carbon fertilizer that supports regenerative agriculture practices and reduces farm dependence on chemical fertilizers. Even though we have accomplished so much, we need to continue our expansion if we are to help reach our nation’s goal of cutting GHG emissions by 2035.”

Advocating RNG Adoption

Like most burgeoning industries, the success of RNG projects shouldn’t merely be measured by capital employed. A better way of tracking growth is to look at the economic and environmental impact through job creation, gross domestic product, and emissions reductions. One of the most effective ways for a young industry and new technology to achieve mass adoption is to get as many players involved as possible. Given the localized nature of the US agriculture industry, Vanguard saw an opportunity to work with small and regional players by creating the Farm Powered Strategic Alliance (FPSA) and the Farm Powered Sustainability Heroes (FPSH) programs. “Our partnership with family farms is at the core of Vanguard Renewables’ mission,” said Smith. “We work alongside America’s dairy farms to solve manure and nutrient-management challenges and provide them with a diversified income stream by hosting an anaerobic digester on their property. Farms receive an additional income stream for hosting the digester, reduced expenses on fertilizer, methane emissions mitigation, enhanced nutrient management, and improved herd health. We are also the co-founders of two pre-competitive groups of food and beverage companies committed to diverting their processed waste to a farm-powered digester. The FPSA consists of more than 15 members that are major food and beverage manufacturers — launched in 2020 by Vanguard Renewables, Starbucks, Unilever, and Dairy Farmers of America. These businesses are multi-regional and larger in scale. Our second and sister program is FPSH, which is for our smaller, regional, or single-facility companies. We currently have four members in New England, and as we move across the country, we will add more companies to our program.”

FPSA and FPSH are both centered around a commitment to recycling unavoidable food and beverage waste. “We are committed to servicing all our food and beverage waste providers with the best service and providing them with a sustainability story for their organic waste regardless of their size,” said Smith. “With the success of FPSA, the company realized that our smaller and regional food and beverage waste providers were looking for a program that would bring like-minded companies together, where they could share best practices and develop strategies that they in turn could use to reach their own ESG goals. Launched in September 2022, FPSH has become an excellent tool for these smaller companies to have a chance to develop their programs and help decarbonize their businesses.”

The typical customer profile of an FPSH member is a food or beverage manufacturer committed to sustainability that has environmental goals as a core principle of their business. For example, the founding members of the FPSH represent a variety of food and beverage producers. New England Natural Bakers produces natural, organic granola products. Fancypants Baking Co. creates peanut and tree-nut-free products and proudly features the “farm powered” logo on its packaging to show its support for the clean energy movement. Sloop Brewing Co. is a craft beer company that has limited-release cans and collaborates with upstate New York agriculture and industry for sustainable initiatives. “From microbreweries to multi-product producers, FPSH members are single-state or smaller regional leaders looking for partnership and collaboratively beneficial opportunities to meet their robust sustainability goals and reduce food and beverage waste,” said Smith. “To join the program, a prospective company must pledge to capture and recycle as much food waste as possible from their company’s operations and have the desire to participate in meetings and other shared opportunities with colleagues in the food and beverage industry. With the investment by BlackRock and our expansion of farm-powered projects in markets across the United States, it will enable us to grow both the FPSA and FPSH so all businesses in the food and beverage industry, regardless of size, can be a part of the farm-powered movement to mitigate climate change.”

Vanguard is seeing FPSH membership grow far past its initial founding members. The reason for the program’s growth seems to be a blend of federal and state support for environmental programs, industry interest in ESG targets and emissions reductions, and a realization that younger generations will gravitate toward environmentally friendly products and services. In other words, investing in ESG is a way to make more money and do good for the planet at the same time. “Companies of all sizes are putting sustainability and ESG goals at the core of everything they do, and programs such as the FPSH are helping these companies reach some of those targets,” said Smith. “Vanguard’s place in the marketplace is a leading factor in why our pre-competitive programs are gaining traction. Corporate sustainability and emissions reduction goals are increasingly important for public perception, reducing climate change impacts, and complying with local, state, and national legislation.”

Vanguard has heavily invested in the FPSH program because it believes it is the responsibility of companies of all sizes to invest in ESG. “When the Paris Agreement was signed, it outlined a necessary 80% to 90% reduction in global GHG emissions to avoid exceeding the crucial threshold of a 2°C warming,” said Smith. “Although large corporations bear the brunt of global emissions generation, the responsibility for making emissions reductions is not only applicable to those large companies, but also for businesses of all sizes. A survey from McKinsey & Co. found that 66% of all respondents and 75% of millennial respondents consider sustainability when they make a purchase. The FPSH program provides businesses with solutions to their food waste and provides a sustainable story they can proudly promote, letting their customers know they are investing in the environment. Additionally, to meet climate goals, states are implementing new legislation targeting alternative organics waste disposal solutions to mandate recycling of organic waste previously disposed of via landfill and incineration, where it generated as much as 10% of the total GHG emissions in the United States. For instance, the Massachusetts Department of Environmental Protection has expanded its organic waste disposal ban by lowering the threshold on commercial organics or food waste from 1 ton [0.9 tonnes] or more to encompass entities that generate a half-ton or more of these materials. Effective November 1, 2022, this updated waste disposal ban impacts smaller businesses that now must adhere to the rules or risk being fined. Organic waste is inevitable for any food or beverage manufacturer or retailer, big or small, necessitating collaborative solutions such as the FPSH to help businesses have a sustainable solution to recycle their waste.”

The Next 10 Years

Despite being a young company, Vanguard has already been recognized by several different organizations. The company’s FPSA program was recognized as a finalist in Fast Company’s 2021 World Changing Ideas Awards in the Established Excellence category. Vanguard and the Goodrich Farm received the 2021 Outstanding Dairy Farm Sustainability Award from the Innovation Center for US Dairy. The company also received the 2020 Energy Vision Leadership Award for its work in organics-to-renewable energy. In 2018, it was named the Organics Recycler of the Year by the National Waste and Recycling Association. “We are consistently recognized for our efforts in the organics waste and renewable energy sectors because of our commitment to creating authentic, innovative, and sustainable solutions,” said Smith. “As the national leader in waste-to-energy projects, we have a platform to exhibit tangible and sociocultural changes in how the country views waste. And we work toward that mission every day.”

“The next 10 years will be crucial to mitigate devastating climate change impacts,” said Smith. “As such, we expect tremendous growth in the FPSA and FPSH programs as our services become available in new areas and more companies work to achieve ESG goals and commitments. As the company expands, our partnerships with new food and beverage waste providers will be invaluable to the success of Vanguard’s co-digestion projects. We are also looking at new ways to innovate in the renewable energy space and looking at complimentary partners to help expand into new areas of our business. Yet, our focus will be forward-thinking and with a vision to create bigger and better impacts for our customers.”