ENERTRAG, one of the largest renewable energy companies in Germany, has signed a contract with Elogen, a GTT Group company, for the development and production of a 10-MW proton exchange membrane (PEM). Elogen will install its technology at the Osterweddingen industrial park near Magdeburg, Germany. Scheduled for completion in 2024, the project is one of many green hydrogen projects currently being developed by ENERTRAG in north and middle Germany.

“ENERTRAG is very proud to accomplish this project, at this great location in the middle of Germany, with many possibilities of deployment, both in industry and in the mobility sector,” said Manuela Blaicher, head of PtX Project Development at ENERTRAG. “With this reference plant, we will produce hydrogen from renewable energies on an industrial scale.”

The Elogen electrolyzer will produce up to 4.4 tons (4 tonnes) of green hydrogen per day. According to ENERTRAG, the electrical energy needed for electrolysis will come exclusively from renewable sources. The electrolyzer will enable the power system to compensate for wind and solar fluctuations. Green hydrogen produced using the electrolyzer will be used to decarbonize heavy industry, as a fuel for long-haul transportation, to generate electricity during periods without wind or solar power, and to feed into hydrogen pipelines.

For the compression, storage, and filling necessary, ENERTRAG enlisted Streicher Anlagenbau (Streicher) and Neuman & Esser. Streicher is responsible for the technical and commercial project management, the planning of the overall plant, and the coordination of the project partners involved. Streicher is also responsible for the piping, storage, and system completion tasks associated with the project.

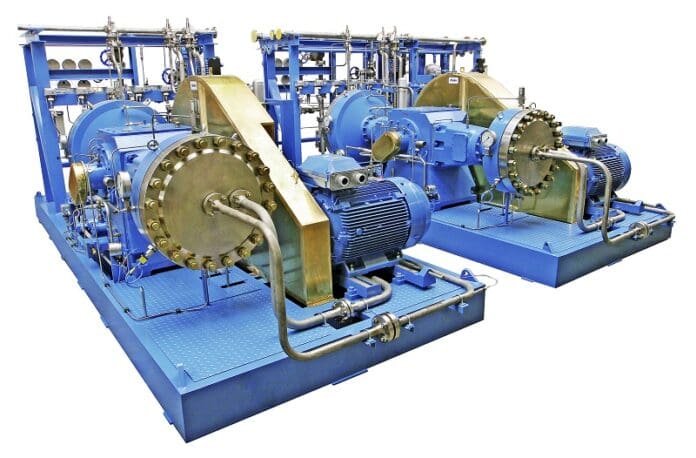

Neuman & Esser will supply the necessary compressor units and support Streicher in integrating them into the overall plant. A total of eight diaphragm compressors (4+4, in two project phases) will compress the hydrogen for various applications. Four compressors will compress 90 kg of hydrogen per hour to 1754 psi (121 bar) for injection into the natural gas grid and another four will compress 45 kg per hour to 7266 psi (501 bar) for trailer filling. In addition to direct use of the hydrogen produced in the electrolysis process by local consumers, the gas will be further compressed for transport and storage.

“Both the single-stage feed and the two-stage filling compressors are diaphragm compressors of the Neuman & Esser brand Andreas Hofer Hochdrucktechnik and use the same proven compressor crankcase size,” said Guido Harsch, sales manager at Neuman & Esser. “The diaphragm heads are of course adapted to the respective application. In the first project phase, two compressors will be installed for each pipeline feeding and trailer filling.”

According to Neuman & Esser, the company’s experience with bottle filler units is incorporated in the design, as is its experience building compressors downstream of electrolyzers.

The compessors will be manufactured in Mülheim and Wurzen, Germany. Planned delivery is March 2024, with customer handover expected in June 2024.

Headquartered in Germany with locations around the world, ENERTRAG provides all services related to renewable energy. As an energy producer, the company has an annual production of 1.38 million MWh. The company operates and maintains wind turbines, grids, and complete integrated power plants.