GE announced that it has submitted a plan to construct two new manufacturing facilities in New York if it wins a sufficient volume of orders from customers in the State’s ongoing solicitation for up to 4.6 GW of offshore wind. To support localized content and New York’s vision to become the nation’s offshore wind manufacturing hub, GE proposed building the factories with Carver Companies at their Port of Coeymans site. GE said that these factories are designed to advance New York as the foundation of a clean energy economy while supporting the local community through durable jobs and positive economic impact

Blades Facility

Should GE receive sufficient order volume, LM Wind Power, a GE subsidiary, is ready to build a facility to manufacture offshore wind turbine blades. GE estimates that the facility would create approximately 650 direct jobs, with approximately 35% of those jobs coming from disadvantaged communities. Approximately 900 additional indirect jobs and more than 500 construction jobs would be created along with millions of dollars of related economic benefits.

Nacelle Facility

GE Vernova, GE’s portfolio of energy businesses, proposed building a facility to build nacelles, which house the generating components of a wind turbine. This facility would create approximately 220 direct jobs, with approximately 35% of those jobs coming from disadvantaged communities. Additionally, almost 500 indirect jobs and approximately 500 construction jobs would be created along with millions of dollars of related economic benefit.

Helping Disadvantaged Communities

GE’s proposal includes specific commitments to hire and train new employees from economically disadvantaged communities. For example, the company will launch an outreach program called Pathways to Wind to provide historically underserved communities exposure, education, and training in the emerging offshore wind industry. In support of that program, GE has engaged 24 educational institutions, including Office of Workforce Development and Community Education at SUNY Schenectady County Community College and SEAT (Social Enterprise and Training) Center, and signed 15 memorandums of understanding (MoUs) with New York entities that will enable the company to enhance diversity and inclusion in its efforts to staff the facilities.

GE believes its approach to environmental compliance and mitigation will help to ensure that the development and operation of the offshore wind turbine blade and nacelle facilities at the Port of Coeymans will satisfy all federal, state, and local laws. The approach is meant to contribute to the advancement of sustainable development practices in the state and beyond.

Leveraging Technology

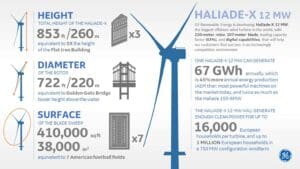

The two facilities would produce components for the next generation of GE’s Haliade-X offshore wind turbine. An earlier version of the Haliade-X was the first 12-MW turbine in the industry and the only one to have full type certification to operate at 14.7 MW. That model of the Haliade-X has been operating for three years and has been selected by several customers, including for the 3.6-GW Dogger Bank Wind Farm. That project will be the largest in the world when completed. Others that have selected the earlier model include the 800-MW Vineyard Wind project that will be the first large-scale offshore wind project in the United States, and the 1100-MW Ocean Wind 1 project. The next generation model of the Haliade-X builds off the platform of its predecessor but contains some design changes and upgrades.