ESG Considerations For Frac Fleets

GD Energy Products (GDEP), a solutions provider for the frac, drilling, and well servicing pumps market, and Catalyst Energy Services, an emerging stimulation service company specializing in hydraulic fracturing treatment, announced their partnership to bring high-horsepower, lower-emissions technology to hydraulic fracturing. Together, the companies are committed toward innovating and testing technology that improves operations and ESG performance.

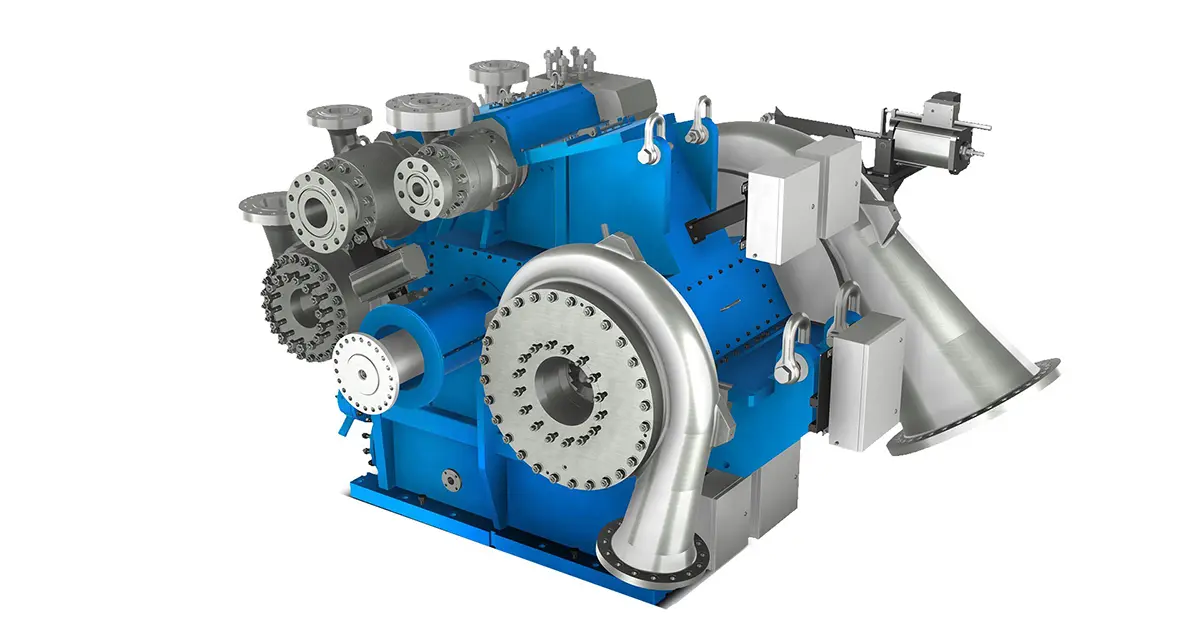

Catalyst Energy Services selected GDEP’s Thunder 5000, a quintuplex pump with an 11-in. (279-mm) stroke rated for 5000 hp (4327 kW), to safely maximize flow at a slower operating speed in its patents-pending, eco-conscious frac solution, VortexPrimeÔ. The pump contributes to the proprietary technology within VortexPrime that reduces the number of trucks in its fleet from 20 to eight, enabling faster setup and take-down, making it a viable option for remote and hard-to-reach sites. To date, VortexPrime has completed more than 12,000 stages and provided both pump and operational data to help the companies continually improve performance.

“Frac service providers and operators are under immense pressure to reduce carbon emissions,” said Larry Kerr, CEO of GDEP. “Catalyst Energy Services is clearly focused on introducing technology that will reduce emissions and waste, while increasing operator and investor return on investment. Primed for more energy-efficient performance, GDEP’s Thunder 5000 can be driven by electric, dual-fuel, or gas turbine engines. We are committed to a successful partnership with the Catalyst Energy Services team and are proud to provide the ideal pump to support environmentally sustainable operations.”

Catalyst Energy Services’ VortexPrime solution features direct-drive turbine technology powered by natural gas, thereby reducing up to 40% of carbon dioxide-equivalent greenhouse gas emissions, decreasing footprint up to 55%, and eliminating up to 99% of waste compared to conventional diesel frac fleets.