Wood-Based Wind Turbine Towers And Blades Gain Traction

In 2021, wind energy accounted for 6.7% of global electricity generation, which was double the share of solar energy. Wind energy is an even bigger deal in the United States and Europe, contributing 9.2% of US electricity generation in 2021 and a staggering 15% of European Union and United Kingdom electricity generation in 2021. The larger EU/UK share is due to a record amount of added wind energy capacity in 2021.

Although wind energy installations continue to show potential, there are a few glaring challenges. The first is economics. Rising interest rates make it less cost efficient to finance projects with debt. Since wind energy projects take years to pay off and are incredibly capital intensive, they are particularly prone to rising interest rates. However, the burden of rising interest rates is partially offset by favorable government policy toward renewable infrastructure projects. The second challenge for wind energy is the environmental impact of the raw materials that go into these projects. Wind blades are often made with fiberglass and carbon fiber, which have damaging production practices. They are also hard to recycle. Blades often end up in landfills as legacy projects get decommissioned in favor of more efficient modern wind farms. Wind turbine towers are mainly made from concrete and steel. According to the US Geological Survey, 66% to 79% of wind turbine mass is due to steel, followed by fiberglass, resin, and plastic at between 11% and 16%, iron or cast iron at 5% to 17%, copper at 1%, and aluminum at 0% to 2%. The environmental impact of mining, refining, and transporting raw materials for wind projects is damaging to the carbon profile of the wind energy industry. To be fair, most low-carbon industries are running into similar issues. The electric vehicle (EV) industry is heavily criticized for the raw materials needed to produce batteries. Cobalt from the Dominican Republic of the Congo, lithium from Chile, and a complicated supply chain that involves nickel, refining, cathode production, and cell production (and the human rights violations that go into producing some of these materials) means that an EV must be driven around 50,000 miles (80,467 km) before its carbon footprint is lower than a comparable internal combustion engine vehicle.

More efficient supply chains and technology are two ways to make low-carbon industries more sustainable. An increasingly intriguing prospect for the wind energy industry is the process of making wind blades and towers with laminated veneer lumber (LVL), a wood-based material suitable for wind power construction. Pound for pound, LVL is stronger than steel, and is much more sustainable than the production process of materials like concrete, steel, carbon fiber, and fiberglass.

Stora Enso is a Finnish global supplier of mass timber products, including LVL. A core part of the company’s offering includes the replacement of less environmentally friendly materials with wood. Stora Enso is partnering with German startup Voodin Blade Technology GmbH (Voodin Blades) to develop sustainable wind turbine blades from wood. Sora Enso is also partnering with Swedish company Modvion to use wood for wind turbine towers.

Stora Enso And Voodin Blades

In November, Stora Enso and Voodin Blades signed a partnership agreement to develop wind turbine blades from wood, which will also involve creating a new sustainable supply chain. The two companies are working on producing and installing a 65.6-ft. (20-m) blade for a 0.5-MW turbine near Warburg, Germany, by the end of 2022. Plans are in the works for a 262.5-ft. (80-m) blade down the road. Stora Enso said it is using 100% sustainable wood to supply the LVL blades, which will give them a high load-bearing capacity while also leading to a low environmental footprint. The LVL material is so lightweight it can be moved around onsite without heavy-duty equipment, which further lowers costs and emissions. “With the current energy crisis and ambitious decarbonization goals, wind energy has never been more in demand,” said Lars Völkel, executive vice president of the Wood Products Division at Stora Enso. “Through this partnership with Voodin Blades, we further accelerate our ability to develop a sustainable and competitive supply chain for the growing market of wind turbine blades.”

According to Stora Enso, tens of thousands of ageing blades end up in landfills. By developing blades with sustainable wood, Stora Enso and Voodin Blades can make the blades lighter and reduce the overall dependency on fossil fuel extraction. “The wind industry is a key driver toward carbon neutrality and needs to become 100% sustainable and environmentally friendly,” said Joachim Knapp, mechanical engineer and automation expert with Voodin Blades. “With the installation of the 20-m blade, we are opening a path toward a more sustainable future. In time we will start to develop and manufacture blades for future multi-MW turbines.”

Stora Enso is providing 100% sustainable wood for the new blades. The first 20-m blade will be developed using Stora Enso’s LVL, a mass timber product that has a high load-bearing capacity that easily supports largescale rotary blades.

Stora Enso And Modvion

In addition to its collaboration with Voodin Blades, Stora Enso announced a partnership with wood technology company Modvion to establish wood as the “material of choice” for wind turbine towers. The collaboration’s purpose is to demonstrate the vast possibilities in using wood in demanding constructions.

Like Voodin Blades, Modvion uses LVL for its projects. Unlike Voodin Blades, which is experimenting with LVL-made wind blades, Modvion is focused on using LVL for the construction of the wind turbine towers. The company’s towers are built in lightweight modules. According to Modvion, this process means the towers can be transported in segments on public roads without permits or road reconstructions. The towers can also be built higher than existing towers, which grants access to stronger winds and more cost-efficient energy production. “As one of the largest sawn wood producers and private forest owners in the world we play an important role in the transformation to a greener society,” said Völkel. “By contributing our expertise to Modvion we can further help make a difference in mitigating climate change and supporting the EU’s drive to increase renewable energy production.”

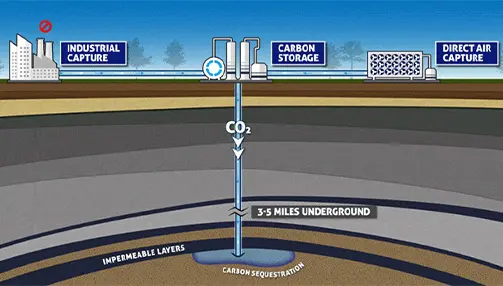

According to Stora Enso, using wood can reduce the carbon dioxide (CO2) emissions for the tower by 90% while also storing CO2 that has been taken up by trees during their growth. As wood-based wind farms are retired in the future, their materials can be recycled and used in new projects, which provides lasting environmental benefits. “The commitment of Stora Enso to replace fossil-based materials with renewables is a perfect match for Modvion,” said Otto Lundman, CEO of Modvion. “To solve the climate crisis, we need more renewable energy as well as increased use of sustainable, wooden constructions. Together with Stora Enso we can enable both.”

Modvion’s US$380 Million Deal With RES

In October, Renewable Energy Systems Group (RES), the world’s largest independent renewable energy company, signed a letter of intent to include Modvion’s wooden wind turbine towers in future wind energy projects. The agreement is meant to make RES wind farms more sustainable and includes a US$380 million order for Modvion towers. RES will now promote the modular wood-based turbine towers to its suppliers in the hopes that turbine manufacturers will purchase wooden towers and use them in RES developed wind farms. The companies estimate that using renewable materials like wood instead of steel and concrete reduces emissions for the entire turbine by 30% because the tower acts as a carbon sink. “Innovative solutions that make our renewable energy projects even more sustainable is something we want to promote,” said Matilda Afzelius, CEO at RES in the Nordics. “RES has committed to the Science Based Target Initiative which focuses on halving emissions before 2030 and achieving net-zero emissions before 2050 and innovations such as Modvion’s are beneficial for reaching such targets.”

According to the agreement, Modvion will continue to supply RES-developed wind farms with around 20 towers per year from 2026 to 2036. “RES shares our vision of a future with carbon-neutral wind power,” said Lundman. “RES wind farms will become the most sustainable in the world when we provide emissions-free towers. We need more companies like RES to lead the way in building renewable energy with renewable materials.”

Modvion believes its patented innovation is also beneficial when it comes to building tall towers, something the industry is striving for. Building with wood means lighter towers and less need for expensive reinforcements. “In order to generate the most cost-efficient wind energy we need to build taller turbines,” said Afzelius. “That’s where Modvion’s solution becomes very interesting. Being able to reach the stronger winds at heights of 951 ft. [290 m], while reducing emissions, is an offering we want to include in our projects as soon as possible. As well as something that aligns with RES’ vision to create a future where everyone has access to affordable, zero-carbon energy.”