GE Renewable Energy Signs MoU With Arafura Resources For Rare Earth Metals

Arafura Resources Limited and GE Renewable Energy have signed a non-binding memorandum of understanding (MoU) to jointly co-operate in the establishment of a sustainable supply chain for neodymium and praseodymium (NdPr) which are rare earth metals that are central to the energy transition. The parties will negotiate a long-term sales agreement for GE to purchase NdPr from Arafura’s Nolans Project in central Australia.

The definitive and binding offtake agreement would be subject to key customary conditions being satisfied, including Arafura securing project funding to develop the Nolans Project and completion of construction, development, and commissioning of the Nolans Project.

The MoU also outlines a potential strategic equity investment by GE in Arafura that will be considered and negotiated in due course.

The agreement was unveiled during the Sydney Energy Forum, a summit hosted by the Australian Government and the International Energy Agency focused on securing clean energy supply for the Indo-Pacific.

The Nolans Project in Australia’s Northern Territory is a globally significant resource for NdPr with the capacity to support a value chain supplying nearly 5% of the global demand over a projected mine life of 38 years with expansion potential. With its ore-to-oxide business model that includes waste management certainty, it provides customers with a product supply chain that is both transparent and traceable. Nolans has the potential to create significant employment opportunities and intergenerational change to the region, with projections of new jobs in Australia, including a construction workforce of 620 and 280 ongoing operational roles.

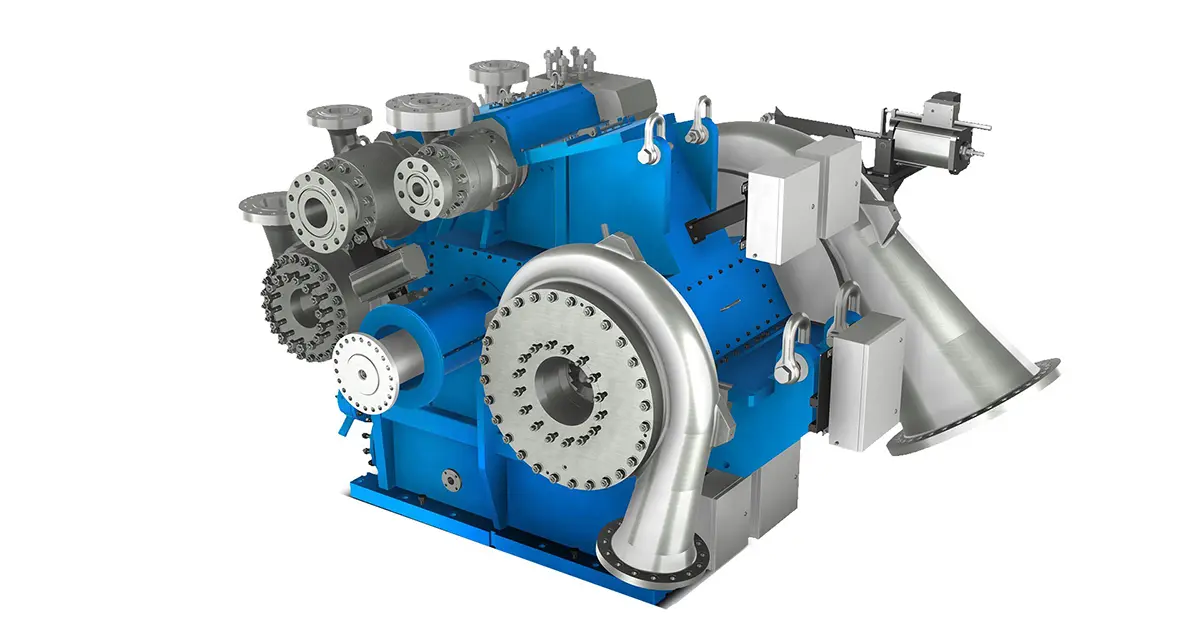

Rare earths are essential materials for NdFeB magnets used in electric vehicles (EVs) and clean energy technologies, with magnets an essential component for the offshore wind industry, consuming more than 600 kg of NdFeB magnets for every MW of wind turbine generation capacity. A secure rare earths supply for GE de-risks the magnet value chain, provides supply security, and supports the growth of the local offshore wind sector.

The MoU recognizes the strategic nature of NdPr, a critical mineral required in the manufacture of high performance NdFeB permanent magnets and charts a path for GE and Arafura to jointly co-operate in the establishment of a diversified and sustainable supply chain. The engagement between GE and Arafura will help strengthen the supply of sustainable materials critical to the energy transition objectives of GE customers in the European Union, United States, and Australia.

Having GE as another foundational offtake partner will provide Arafura with product sales diversification both geographically and into new sectors like the offshore wine turbine market. Analysts are forecasting the volume of annual offshore wind installations to more than triple, from 6.1 GW in 2020 to 23.1 GW in 2025, bringing its share of global new installations from 6.5% to 20% by 20251. This exponential growth in demand is driven by the need for energy security and the role of renewable energy to meet the Paris carbon-neutrality target by 2050.

“The signing of this MoU to collaborate with a Tier 1 original equipment manufacturer is a terrific outcome,” said Arafura’s Managing Director and CEO Gavin Lockyer. “Long-term, Nolans NdPr may be used in magnets critical for power generation from GE’s Haliade-X 12-MW offshore wind turbine. It is very gratifying that a new supply chain model, along with transparency of the value chain, will ensure we know exactly where our NdPr will be used, whether it is in a particular EV model or a series of wind turbines. The contribution of Nolans NdPr to enable clean energy technologies to decarbonize the world is becoming more and more apparent.”

GE Renewable Energy announced in October 2021 that the company had signed a non-binding MoU with General Motors to evaluate opportunities to improve supplies of heavy and light rare earth materials and magnets, copper, and electrical steel used for manufacturing of EVs and renewable energy equipment. The two companies signed a co-sourcing agreement earlier this year as the next step in that process. Metal alloys and finished magnets produced from rare earth materials are critical components used in manufacturing electric motors for automotive and renewable power generation.