Enter The Electric-Drive Mako

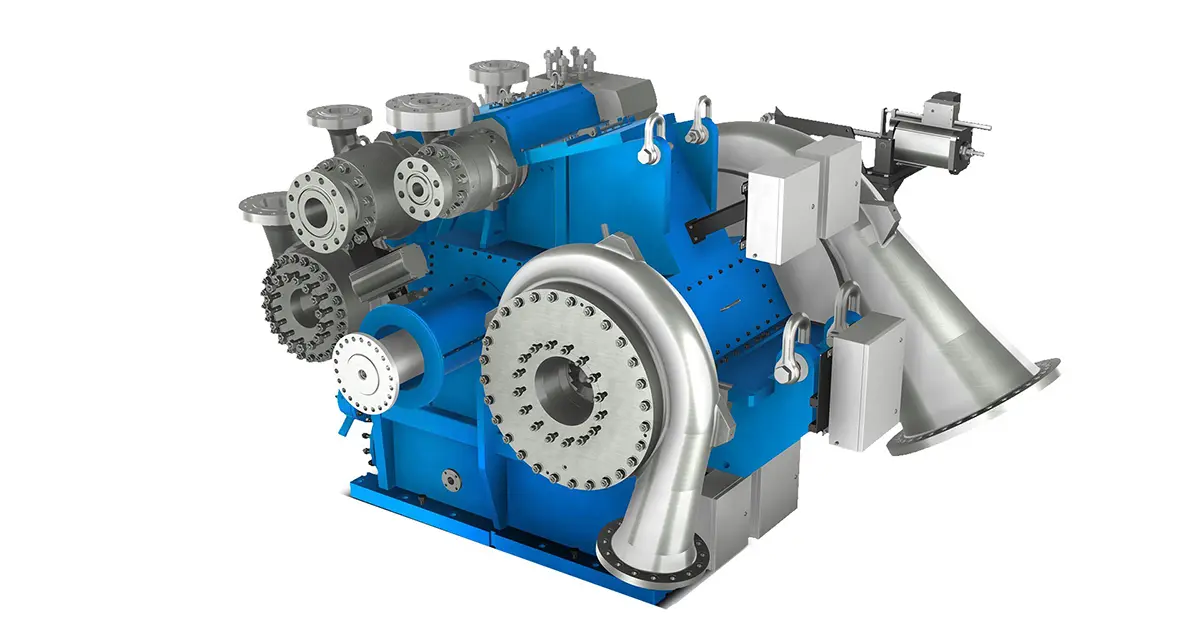

Genis Holding LLC (Genis) introduced the Mako G225 LE in 2019. Comprised of a 228-hp (170-kW) Power Solutions International engine driving an NG 3-stage, 2-throw balanced opposed compressor connected via a drive shaft, the Mako introduced the industry to a new compressor and cylinder design, a new engine, and a new cooling system.

Designed for versatility, the Mako G225 LE can operate on a variety of fuels, including natural gas, propane, and wellhead gas. In addition, Genis offers a bolt-on conversion kit that allows the unit to swap out its gas engine with an electric motor. “The Mako is the first package that’s ever been designed to be gas engine or electric drive at any phase,” said Matthew Pierce, managing partner at Genis. “This allows flexibility for an end user without an operational learning curve when the driver is swapped between a gas engine and an electric motor, or vice-versa. The compressor is the same. The cooling system is the same. The Mako was engineered to allow operators to go back and forth between drivers quickly and easily as needed. With increasing pressure to ‘go electric’ it takes time and dollars to make that transition. Being able to ‘go electric’ while the unit is already on location is a solution that we are excited to give to our industry.”

Following the success of the Mako G225 LE, the popularity of the conversion kit, and the ever-changing emissions landscape, Genis has introduced the eMako. Powered by a TECO-Westinghouse electric motor, the eMako, like its engine-driven counterpart, targets gas lift, injection, and gas gathering applications up to 1440 psig (992 bar) and can move up to 1.5 MMscf/d (42,000 m3/d).

“Where the Mako G225 LE is a gas driver that can be swapped with an electric motor, the eMako is an electric unit that will accept a gas engine,” said Pierce. “There’s no design change between the gas engine and electric drive unit. No additional welding, and no extra fabrication; this swap can be made in the field with two people and a crane truck in a matter of hours.”

Cooling

The eMako uses the same patented gas cooling system introduced with the Mako G225 LE. The modular system uses two 24-volt, on-demand, variable speed fans on each stage of compression. The fans can be programmed to the temperature needs of the application. They can speed up, slow down, and turn on and off as needed. “The onboard central processing unit optimizes interstage and final discharge temperature to reduce and possibly eliminate liquid dropouts between stages of compression,” said Pierce. “We have more affected surface area, more passes with less pressure drop, and increased flow. Overall, we have a more efficient, controllable cooling system at a lower horsepower draw than has ever been offered.”

The cooling design is connected via flexible pipe spools to the other process gas components. Having a modular arrangement allows the product to optimize its flow path in length, materials, and changes in direction. According to Pierce, the layout eliminates large amounts of process gas piping, corresponding to more horsepower consumed in the pressure drops, as well as using less material, which attributes to reduced weight and overall cost.

Mobility

All Mako series compressor packages are designed for mobility. “All you need is a truck and someone with a Class C license,” said Pierce. “The entire package is less than 7.5 ft. (2.2 m) tall and only weighs about 16,000 lb. (7257 kg), so it can fit into a 20-ft. (6-m) shipping container. In addition, each package has wheels and rail runners down the middle. The skid design is derived from the base of a common roll-off container. No special permitting is required to transport either model.”

Changing The Industry

Since its inception, Genis has made it its mission to disrupt the status quo. The introduction of the Mako G225 LE not only introduced the industry to a new compressor and cylinder design, but it also represented a step change in gas compression packaging. Its standardized design, as opposed to being an individually customized package, proved to be an enormous hit with end user.

Next, Genis unveiled a new approach to product sales and support, introducing its dealership network. “The concept it simple. Genis manufactures compressor packages and gas coolers. Dealers upgrade each unit as needed for various application,” said Pierce. “By offering a standard, proven solution, we can reduce costs considerably, especially when compared to a similar sized, completely customized unit that is pursued through a traditional packager.”

In 2020, Genis began commercial production of its Aeris Cooling System (Aeris). Initially introduced as the cooler on the Mako G225 LE compressor package, Aeris is a standalone unit that presents a different approach and method to cooling natural gas and liquids. Developed in partnership with Fresco Thermal, Aeris uses a cooling design that allows up to four individual cells on a single skid to operate independently in either automatic or manual mode. These cells can cool gas in any combination of parallel, series, or separate process flows.

With its latest offering, Genis continues to challenge industry norms by introducing a standardized offering for the electric-drive compression market. “The push to electric-driven compression is happening due to emissions compliance regulations and more end users adopting ESG policies. We see a lot of opportunity in the market,” said Pierce. “Ultimately, we are not here to develop the same compressor package already on the market. The goal of Genis is to pursue product innovation through research and development and give the industry alternatives that meet or beat the competition on all fronts, including performance, cost, and usability.

“We used the 200-hp [149-kW] class Mako as opportunity to establish ourselves — to get people familiar with the concept and the design and show that there is a new way to do this,” added Pierce. “We will soon be introducing two new units — one is a 3.5 MMscf/d [212,000 m3/d] compressor package, and the other is a 7.5 MMscf/d [99,000 m3/d] unit. People traditionally focus on the horsepower, but what matters most is the how much gas it is moving. Customers have been asking us for larger units since we first showed them the Mako. Those units are no longer on the horizon. They are coming down the hill right now.”