Are Phillips 66’s Renewable Vows In Jeopardy?

For 2022, Phillips 66 has earmarked US$1.9 billion toward growth projects, of which 45% (US$855 million) is expected to go toward lower-carbon opportunities, including the company’s Rodeo Renewed (Rodeo) project. Rodeo captured headlines in late 2020 and early 2021 as Phillips 66 said it would be the company’s largest environmental, social, and governance (ESG) investment in its history. Then, the news went quiet, and we didn’t hear many updates on Rodeo for a while.

However, Phillips 66’s latest capital program shows it is making progress and more funding is on the way this year. The company released a 40-page report on Rodeo in October 2021 and has since followed up on that report with executive commentary. Here’s where Rodeo Renewed stands, how it complements Phillips 66’s other low-carbon projects like the Humber Refinery, and what Phillips 66 needs to do to make sure its renewable vows aren’t in jeopardy.

A Tall Order

In 2020, Phillips 66 announced plans to transform its San Francisco Refinery (Rodeo Refinery) in Rodeo, California, into the world’s largest renewable fuels plant (see “Renewable Vows,” Q1 2021 ESG Review, p. 12). But to do that, it must completely rethink how its existing refinery operates.

(Image Courtesy Of Phillips 66)

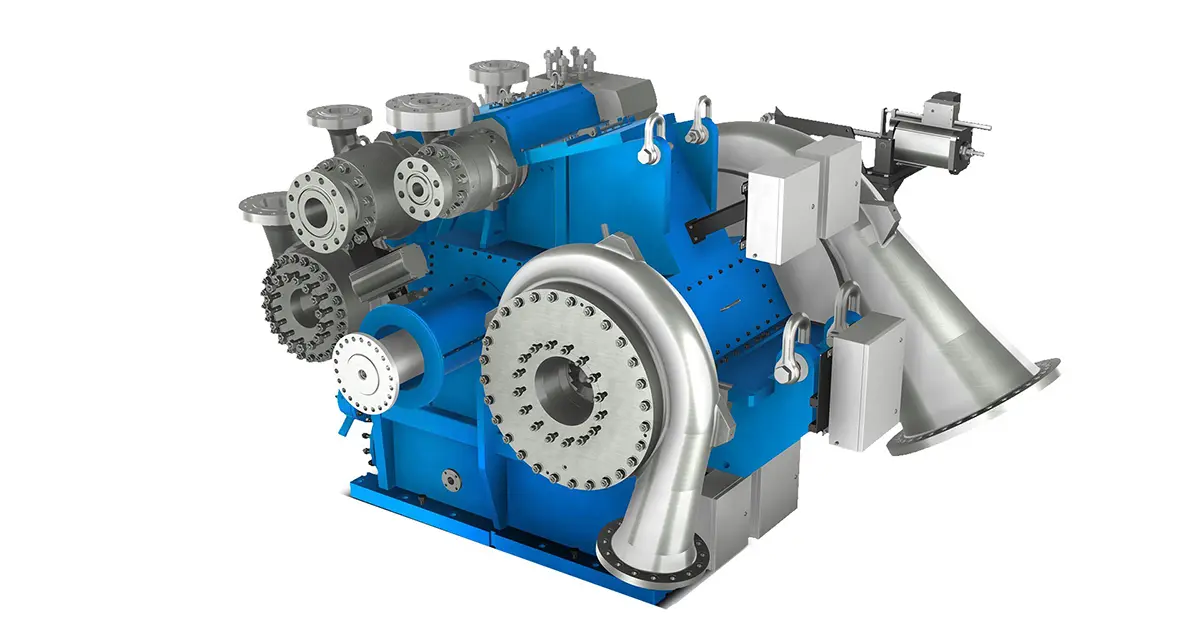

The Rodeo Refinery is an extremely complex system of interconnected machinery, equipment, and processes. It includes several existing major process units, such as the crude distillation unit, the crude coking unit, the unicracker complex, the ultra-low sulfur diesel hydrotreating unit, the hydrotreating-reformer complex, the isomerization unit, the fractionation and caustic treatment unit, the product blending facility, sulfur recovery/amine absorbers/sour water strippers, main and MP-30 flares that safely control excess gas, and the fuel gas center that removes sulfur compounds from raw fuel gas.

In addition to these major process units, the Rodeo Refinery also includes the steam power plant, a butane storage and railcar loading facility, import/export facilities, a wastewater treatment plant, a pressure-relief system/vapor-recovery system, a hydrogen plant, and the carbon plant. The hydrogen plant includes a steam methane reformer furnace, associated stack, and other equipment, including a compressor, cooler, and associated piping. Hydrogen is generated by reacting a petroleum liquid or gas, such as butane or natural gas, with steam in the presence of a catalyst.

The company plans to modify existing process equipment to intake a variety of fuels such as cooking oil, fats, greases, and other feedstocks instead of crude oil. In this way, the refinery would be able to make renewable diesel. Renewable diesel is derived from a renewable source, as opposed to petroleum. Soybeans capture carbon dioxide (CO2) as they grow, which refiners like Philips 66 can use as a feedstock. Renewable diesel is classified as a drop-in replacement to normal diesel, meaning equipment manufactured to run on diesel can use renewable diesel without any additional modifications. If all goes according to plan, the company estimates that the facility will have renewable fuel production of 50,000 barrels per day (bpd).

Construction at the Rodeo site and the carbon plant site is expected to employ up to 500 workers and involve heavy equipment, such as loaders, earthmovers, cranes, and concrete trucks, and lighter-duty equipment, such as welders and compressors.

Project Updates

There are several other smaller projects and timelines working under the umbrella of Rodeo. While the facility continues to refine crude oil, the company converted one of its hydrocrackers to intake soybean-based oils used to produce about 8000 bpd of renewable diesel. This hydrotreater conversion was completed in 2021. “During the year, we began renewable diesel production at the Rodeo Refinery and continued to progress Rodeo, which is expected to be completed in early 2024, subject to permitting and approvals,” said Phillips 66 President and Chief Operating Officer Mark Lashier on the company’s Q4 2021 earnings call. “Upon completion, Rodeo will initially have more than 50,000 bpd of renewable fuel production capacity. The conversion will reduce emissions from the facility and produce lower-carbon transportation fuels. In marketing, we acquired a commercial fleet fueling business in California, providing further placement opportunities for Rodeo renewable diesel production to end-use customers.”

Phillips 66 is using the 8000-bpd conversion as a beta test, giving the company an indication for what it can expect from the full-scale project. At 8000 bpd, this first conversion will have a renewable fuels capacity at around 15% of the 2024 goal — sizeable enough to start setting up supply chains and marketing for renewable diesel but also small enough that production doesn’t exceed demand to overstrain the company’s infrastructure.

Phillips 66 has done an excellent job hitting its early goals. In 2020, it set the goal to partner with companies to secure feedstocks and transport renewable diesel offtake to the California market. It did that. The next step is to have permitting completed in 2022. Once that step is done, Phillips 66 expects to begin conversion of the Rodeo Refinery to work up to the 50,000-bpd renewable diesel capacity.

In 2022, Phillips 66 expects to begin construction of its pretreatment units and repurpose its two high-pressure hydrocrackers to yield the final 42,000 bpd of renewable diesel. From there, the company will expand the initial 8000-bpd supply chain and marketing network to encompass its added capacity. “At the end of the day, we will convert the facility and build the pretreatment facilities for a total capital cost of about US$1 per gallon per year of capacity,” said Timothy Roberts, executive vice president of Phillips 66 midstream. “That’s 50% cheaper than anything else we’ve seen announced and three times cheaper than some of the competing projects we’ve seen. We feel really good that by 2024, we will be a major player in renewable fuels in California and other places in the United States.”

As part of its transition away from fossil fuels toward renewable fuels in California, Phillips 66 has plans to shut down its Santa Maria refining facility in Arroyo Grande, California, starting in 2023. It also plans to shut down its carbon plant in Rodeo, California, in 2023. The Santa Maria refinery is part of the San Francisco Refinery system, supplying the refinery with intermediate products through a 200-mile (322-km) pipeline, which is also expected to be decommissioned in the coming years.

Phillips 66 will begin decommissioning crude oil pipelines throughout California in the coming years. If Rodeo is successful, the company could very well expand its alternative fuel capacity within the state before expanding to other progressive states.

Rodeo Renewed Profitability

Aside from successfully completing Rodeo on time and under budget, one of the greatest challenges for the project will be to sustainably source feedstocks and produce and sell renewable diesel for a profit. However, Phillips 66 believes it has unique advantages over its competitors to acquire feedstocks. “We don’t see any issue with the feedstock availability, although it may be challenging for those that maybe are less commercial, have less logistics experience,” said Brian Mandell, executive vice president of marketing and commercial operations at Phillips 66. “We think between increased acreage and yield, switching from biodiesel, and better aggregation of used cooking oil, we’ll have plenty of feedstock to produce renewable diesel. Prices may vary over time and that’s to be expected.”

Phillips 66 also believes that Rodeo is ideally positioned to have access to a swath of suppliers and end markets for the products it produces. “At Rodeo, we’re on the water so we have access to both domestic and foreign feedstock,” said Mandell. “And we also sit on the US’s greatest demand center, California, so we feel good there. Our commercial organization has been working on feedstock for quite a while. We have offices around the world. We have storage in Asia, Europe, and the United States. We have good relationships with vegetable oil producers. We announced our investment in Shell Rock Soy Processing. For the startup of Rodeo, we purchased soybean oil, canola oil, and distilled corn oil since April 2021. We have strong relationships with tallow producers and aggregators of used cooking oil. In fact, with used cooking oil, we’ve been in that market for more than four years supplying our Humber Refinery used cooking oil from around the world, currently 12 different countries. I think Rodeo will have a maximum optionality in its system, and then we’ll use a linear program to decide what the best and most cost-effective feedstock is based on not just carbon intensity but price and credit generation to the sales market and logistics.”

During its Q4 2021 conference call, Phillips 66 updated investors that the cost of Rodeo is expected to be a total of US$850 million, an increase from its earlier estimate of US$750 million. In response to that news, the company has clarified its approach to feedstocks, achieving positive renewable diesel margins, and how the Rodeo Refinery will leverage its California operations to connect with end users. “When you’re thinking about the renewable diesel margins, you have to think about feedstock, the renewable diesel price, and the credits,” said Phillips 66 Chair and Chief Executive Officer Greg Garland. “The key to renewable production is finding as many feedstocks and as many suppliers as you can and having the logistics to get it to the plant. We’ve set up a global organization to do that. In renewable diesel, the key for us is getting the renewable diesel to the end user. We keep more of the margin that way. In part, our purchase of our commercial fleet fueling business was enabled for us to get some of that product to end users. We’ve taken all the stores in California that we have, and we’ve converted those to renewable diesel as well. We’re going to have as much renewable diesel as we can to the end user.”

The company also discussed the carbon intensity (CI) approval process and potential pathways. “We started up the unit after the last turnaround on basically clean soybean oil,” said Bob Herman, executive vice president of refining at Phillips 66. “And since then, we’ve been able to establish pathways. In California, you run new feedstocks, you get a provisional CI number for them. Then you have to go through a lengthy bureaucratic process to qualify your other feedstocks. Since we’ve done that, we’ve been able to qualify not only the soybean oil but the distiller’s corn oil we’re working on. We’ve got a pathway on canola oil. I think that process will keep repeating itself as we find more and more feedstocks ahead of Rodeo coming up in 2024 that really allow us to take advantage of the lower CI material right away.”

Share Repurchases Versus Growth Projects

Phillips 66 reported US$111.5 billion in 2021 revenue, US$1.32 billion in net income, and US$4.16 billion in free cash flow (FCF). The results were a big improvement from just US$64.13 billion in 2020 revenue, a loss of US$3.98 billion, and negative FCF of US$809 million — all of which were nine-year lows. Even with 2021’s improvement compared to 2020, Phillips 66 is far from the profitability it had prior to the pandemic.

Despite still being in recovery mode, Phillips 66 expects to have an excellent year in 2022, which begs the question of whether it will use excess capital to increase the dividend, buy back its own stock, or invest in the business. Judging by management’s commentary, Phillips 66 appears committed to investing in its ESG goals even if it comes at the expense of fewer share buybacks.

“We’ve been out of share repurchases, and it’s time to step back into those,” said Garland. “And I think for all the right reasons, we want to keep capital constrained across the portfolio over the next couple of years. We just don’t think those investable opportunities that will hit our return hurdles are going to be there in the next two years in the midstream business. And we’ll see where renewables take us. But right now, the biggest project in front of us is Rodeo. That is almost a mega project by any standards. I think there’s still big things going on around the portfolio in terms of growth, and then you add on CPChem and the two mega projects they’re looking at. The whole idea is to free up more cash for debt repayment and getting back into share repurchases.”

Put another way, Phillips 66 wants to get to a point where it can improve its balance sheet and foster shareholder value. But that will be challenging until it completes some of its major projects, such as Rodeo and upgrades to the Humber Refinery.

Reducing Emissions At The Humber Refinery

Rodeo Renewed is Phillips 66’s largest low-carbon project in terms of investment dollars. But it is far from its only project. On March 22, 2022, Phillips 66 announced the goal to reduce onsite CO2 emissions at its Humber Refinery in support of the United Kingdom’s carbon neutrality goals. More specifically, Phillips 66 is pursuing the use of lower-carbon hydrogen to replace natural gas as the fuel source needed to refuel industrial heaters. These heaters are integral to the refining process because they provide the heat needed to produce transportation fuels from hydrocarbon chains.

Phillips 66 Limited, a wholly owned subsidiary of Phillips 66, committed US$654,500 toward refueling the project, which was matched by the UK Research and Innovation fund, the largest source of public funding for research and innovation in the United Kingdom. Worley and John Zink International received contracts for the feasibility study. Phillips 66 said that the Humber region is estimated to emit around 13.67 million tons (12.4 million tonnes) of CO2 every year, making it the UK’s most carbon-intensive industrial cluster. “The Phillips 66 Limited Humber Refinery is a major asset to the region, providing more than 1000 jobs and significantly contributing to the regional economy,” said Phillips 66 in a statement. “Refueling the Humber Refinery project will demonstrate at large scale how renewable hydrogen can be used to decarbonize the refinery. It further complements the Humber Zero Project, which stands to capture CO2 from the main centralized stacks, helping to reduce overall Humber Refinery emissions by more than 90%.”

The refinery has a clean product yield capability of 81%, a Nelson Complexity Factor of 11.8, gasoline production of 95,000 bpd, distillates production of 115,000 bpd, crude throughput of 221,000 bpd, and total throughput of 245,000 bpd.

Aside from the refueling project, Phillips 66 has tested other ways to reduce air emissions, such as emissions from flares when flaring is unavoidable at the Humber Refinery. The Humber Refinery reduces air emissions from the coking production processes by carrying venting from the coke drum to the gas compressor to recover as refiner fuel gas (RFG) rather than flaring.

Another way the refinery can reduce emissions is by installing larger compressors with higher operating load capacities. The refinery has two separate dedicated flare systems, No. 1 Flare and No. 3 Flare. Unrecovered gases are routed to No. 3 Flare, which is the low-pressure flare and has a flare gas recovery system. According to Phillips 66, the dual compressor system associated with the No. 3 Flare is used during steady-state operation to recover gases continuously sent to flare during routine operation. The high-pressure system of the No. 1 Flare lacks a fuel gas recovery system. Normally, the Humber Refinery operates in fuel gas balance where production is the same as consumption, so flaring on No. 1 Flare is limited to pilot gas. Put another way, there’s no real flaring aside from essential purge gases. However, if the fuel gas system goes into a surplus due to a refinery heater trip or another reason, then the flare gas flow increases substantially. Phillips 66 said that when this happens, No.1 Flare becomes unsuitable for flare gas recovery. The company notes that the compressors would need to be oversized to recover the additional loads, but that the compressors would end up sitting idle for most of the time because the flare load would normally be below their minimum stable operating load.

Other Low Carbon Projects

In addition to upgrading the process systems at the Humber Refinery, the refinery is also working on ways to produce low-carbon fuels. The refinery began producing renewable diesel in 2018 and is working on producing sustainable aviation fuel (SAF) as well (see “Blue Skies Ahead,” First Quarter 2021 ESG Review, p. 4).

In December 2021, Humber Refinery landed a deal to supply SAF to British Airways. “It’s a small volume; we don’t run a lot of renewable feedstocks at Humber yet,” said Lashier. “We’re working on a lot of things in Humber to reduce the carbon intensity of the fuels that come from that plant. We’re a supplier to British Airways anyway, so this just kind of extends our reach there. It signals that in Europe, with British Airways, we’re going to expand the business as we expand our ability to run used cooking oils and other renewable feedstocks in Humber.”

One of the major barriers to entry for petroleum refineries to convert to renewable diesel and SAF production are regulatory hurdles. “The reason we were able to make the deal with British Airways is because the European scheme is different from the US scheme, which treats renewable diesel, renewable gasoline, and renewable jet fuel the same,” said Herman. “That’s why deals haven’t been done in the United States yet. But we expect that as part of the Build Back Better plan, we’ll get some incentive and over time, we’ll either get more incentive or airlines will make commitments to pay more for SAF.”

“When you think about the airline business, I mean, their only option today to decarbonize is SAF,” said Garland. “We don’t think hydrogen is going to work in planes, batteries aren’t going to work in long-haul planes. And so, I think they’re anxious to work with the industry in developing SAF. And I think what you’re going to see is contractual relationships developed so they have access to the molecules that are going to be there.”

Adding It All Up

Phillips 66’s efforts at its Rodeo Refinery and its Humber Refinery illustrate the appetite for companies to invest in ESG to reduce emissions and drive profits. Phillips 66 is progressing nicely on its Rodeo targets but faces limitations outside of its control. For example, the company has been able to accelerate improvements to the equipment and processes at the Humber Refinery relatively quickly. It has also been able to expand past renewable diesel into SAF after just a few years of renewable diesel production due a less restrictive regulatory climate and a more receptive end-user market in Europe as compared to the United States. Given the response to SAF in Europe, it wouldn’t be surprising if other US refiners with European operations or European downstream companies continue to invest in renewable diesel and SAF at a faster rate than their American peers.