Demand for lithium batteries is surging. From Tesla to commercial electric vehicle (EV) manufacturers like Oshkosh Defense and Workhorse, technological advancements and lower costs have accelerated international interest in alternative energy. Behind the transition from the internal combustion engine to the electric motor are international raw materials companies like Almonty Industries (Almonty). Based in Toronto, Ontario, Canada, Almonty mines, processes, and ships tungsten concentrate from its Los Santos mine in western Spain and its Panasqueira mine in Portugal. It’s also developing two new mines, the Sangdong tungsten mine (Korea Tungsten Project) in Gangwon Province, South Korea and the Valtreixal Project for tin and tungsten in northwestern Spain.

The Los Santos mine was acquired by Almonty in September 2011 and is located 31 miles (50 km) from Salamanca in western Spain and produces tungsten concentrate.

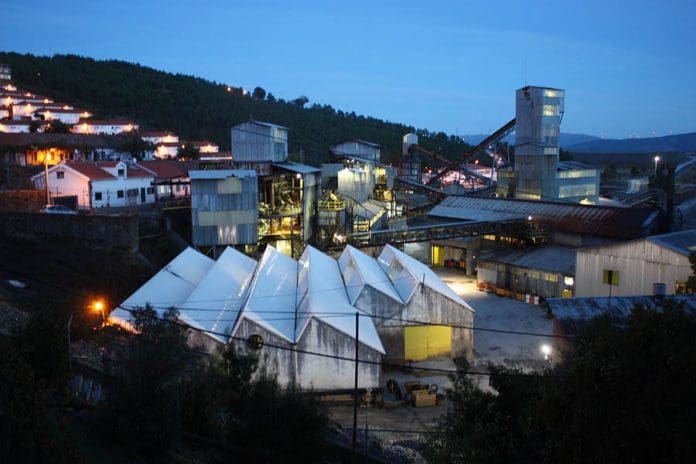

The Panasqueira mine, which has been in production since 1896, is located 162 miles (260 km) northeast of Lisbon, Portugal, was acquired in January 2016.

The Sangdong mine, which was historically one of the largest tungsten mines in the world and one of the few long-life, high-grade tungsten deposits outside of China, was acquired in September 2015 through the acquisition of a 100% interest in Woulfe Mining Corp. Almonty also owns 100% of the Valtreixal Project in northwestern Spain.

Background

Affordable batteries are making it possible for companies to store electricity and harvest renewable power. In the auto industry, batteries are challenging the century-long domination of gas-powered engines. Costs have come down so far and so fast that most car makers expect that EVs, which are generally more expensive than their gas-powered counterparts, will cost the same amount to build within the next five years. EVs are currently the main source of demand for battery cells.

As demand grows and costs continue to fall, batteries will become even more disruptive across industries. Even legacy companies like General Motors announced plans to phase out gasoline- and diesel-powered vehicles from showrooms worldwide by 2035. China currently dominates the market for producing EV batteries. As automakers spend billions to build more plug-in models in the United States, investors are increasing their bets on companies looking to expand the supply chain for batteries and related materials in North America — a region that has long relied on component imports.

New Tungsten Production Sources And Increased Global Supply

“In the last year, there has been an explosive need for EV batteries,” said Lewis Black, CEO of Almonty. “All car manufacturers seem to be following in the same footsteps as Tesla. In fact, Jaguar plans to become an ‘all-electric luxury brand’ by 2025. This shift is also taking place in other motorized segments, including trucks and mining machinery. With the COVID-19 pandemic wreaking havoc on the US and global economies with businesses and manufacturers having to close doors and furlough employees, the global trade markets plummeted to an 11-year low of 41.5%, according to the April 2020 report for the Institute for Supply Management’s Manufacturing Index.”

“As manufacturers set to ramp product back up to produce everything from automobiles, airplanes, and construction tools, they will begin to return to normal production cycles,” said Black. “This also means they will face their usual litany of production challenges. This primarily includes dealing with a strained supply chain on critical raw materials, like tungsten, to produce all of those EV-powered automobiles, cranes, trucks, and more.”

Domesticating Raw Materials To Ease Already Strained Demand

“China controls the market for nearly 35 precious minerals and metals are important to the United States for production and manufacturing, including tungsten. According to the 2019 United States Geological Survey [USGS] Commodity Summaries Report, world tungsten supply was dominated by Chinese production and exports,” said Black.

The USGS report also noted that China’s government regulated its tungsten industry by limiting the number of mining and export licenses, imposing quotas on concentrate production, and placing constraints on mining and processing. “The issue at hand is that China has limited the amount of tungsten exports that can be shipped to the United States, and this has caused a great deal of concern about the overall supply chain of tungsten,” said Black. “With a growing need of raw materials like tungsten on the horizon and an overdependency from this one source, there is an even greater need to domesticate raw materials. The challenge with China being the dominant force for a majority of raw materials includes its legal system. Should the United States have a boom in demand of a certain material from China, its legal system could effectively stop the supply of that particular material.”

New Tungsten Production Will Open The Global Supply Chain

“Fortunately, new entrants into the market have begun tungsten mining projects throughout the world. These efforts are crucially important to increase supply levels and exports to the United States, which will benefit the overall global supply chain of tungsten for production and manufacturing,” said Black. “One project of particular importance is the Korea Tungsten Project located in the Sangdong mine of South Korea, which hosts one of the largest tungsten resources in the world. This mine was the leading global tungsten producer for more than 40 years and it has the potential to produce 50% of the world’s tungsten supply. The project has become a center of focus recently for resource experts, miners, investors, shareholders, and other interested parties around the globe. Global economies of this relaxed supply chain are eagerly awaiting production of tungsten from this region, especially since it will ease China’s hold on the overall supply of this raw material. What’s more, US manufacturers are keenly watching, since additional supply of tungsten from South Korea would help avoid expensive import tariffs of products shipped from China and enacted by the US government.”

Geopolitical Concerns

Increased tungsten supply out of South Korea should help improve overall production. In addition to a concentrated Chinese tungsten market, Almonty is closely watching the ripple effects of the US-China trade war. “The global trade wars have recently heated up, which is costing manufacturers in the process,” said Black. “Currently, the United States has imposed tariffs on more than US$360 billion worth of Chinese goods, and China has also retaliated by imposing tariffs on more than US$110 billion worth of US products. The United States imposed three rounds of tariffs on Chinese imports in 2018, with a fourth round completed in September 2020 on many items with a 15% duty. Hopefully, the Sangdong mine is one example of relief US and global manufacturers will see from the mining and production of tungsten to ease the global supply chain of this precious raw material — a material that is sorely needed for many EV products, both now and in the future.”

ESG Focus

In February 2021, Almonty announced the expansion of its ESG program at its Panasqueira mine and Korea Tungsten Project. At Panasqueira, the company is implementing a 12-month solar program that includes the construction of a 2.5 MW facility. The facility will be capable of producing 4.1 million kWh of electricity per year, which is more than 21% of the mine’s annual consumption. The company is conducting a third-party report at the Sangdong mine to analyze its carbon footprint. Almonty believes it has a unique opportunity to push toward carbon neutrality at its Korean site because energy supplied from the grid to the Sangdong project is 100% renewable.

“As we transition into the wider financial markets of Asia and Australia, and our visibility continues to increase as a significant producer of the strategic metals of tungsten and molybdenum, it has become increasingly important to ensure that we are continually reviewing and developing our ESG focus, which sits perfectly in line with the equator principles around which the Sangdong project is being built,” said Black. “The equator principles were the backbone of KfW-IPEX Bank support. Now, we find that exchange traded funds [ETFs] covering the strategic space require a continuing push across the board regarding our ESG,” (see “An Introduction To ESG,” First Quarter 2021 ESG Review p. 2).

“The aim for carbon neutrality at Sangdong is potentially achievable once underground electric fleets can maintain a charge for an entire shift, which is estimated to be technically possible within the next 18 months,” said Black. “We are extremely fortunate that 100% of our energy comes from a renewable source making the target of carbon neutrality achievable. With Panasqueira, we are dealing with a 126-year-old project, but we now start the process of bringing far greater attention to its ESG. The first phase of this is to provide over 20% of our energy needs from solar. Social programs are already underway for some years now and further programs are also now being evaluated to bring the mine further into the 21st century.”