Floating Nuclear Power Plants

Cooperative Agreement Between Westinghouse, CORE POWER Brings The Advantages Of Nuclear Power Using Evinci Microreactors To Maritime And Coastal Applications

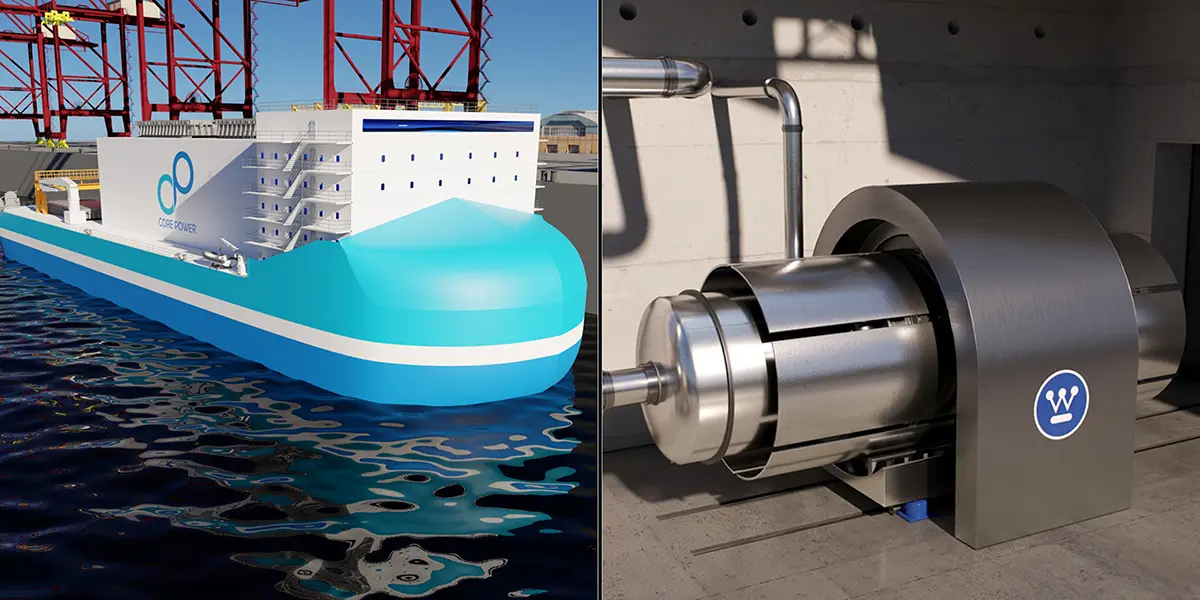

Westinghouse Electric Company (Westinghouse) and CORE POWER announced the formalization of a cooperative agreement for the design and development of a floating nuclear power plant (FNPP) using the eVinci microreactor.

Westinghouse said that FNPPs are a game-changing approach to deploying nuclear energy to islands, ports, coastal communities, and industry. These innovative power plants can be centrally manufactured and easily transported to operation sites, combining advanced nuclear technology with shipyard efficiency. As a highly transportable source of cost-competitive, reliable nuclear power, the companies believe that the eVinci microreactor is perfectly suited for FNPPs. According to Westinghouse, the eVinci microreactor requires minimal maintenance and can operate for eight years at full power before refueling, allowing for reliable long-term power generation at almost any location.

“There’s no net-zero without nuclear. A long series of identical turnkey power plants using multiple installations of the Westinghouse eVinci microreactor delivered by sea, creates a real opportunity to scale nuclear as the perfect solution to meet the rapidly growing demand for clean, flexible and reliable electricity delivered on time and on budget,” said Mikal Bøe, chief executive officer of CORE POWER. “Our unique partnership with Westinghouse is a game changer for how customers buy nuclear energy.”

Under the agreement, Westinghouse and CORE POWER will advance the design of a FNPP using the eVinci microreactor and its heat pipe technology. Based on more than 60 years of proven use, heat pipe technology improves reliability while providing a simple, non-pressurized method of passively transferring heat. Heat pipes in the eVinci microreactor transfer heat from the nuclear core to a power conversion system, eliminating the need for water cooling and the associated recirculation systems. In addition, the companies will collaborate to develop a regulatory approach to licensing FNPP systems.

“With this groundbreaking agreement, we will demonstrate the viability of the eVinci technology for innovative use cases where power is needed in remote locations or in areas with land limitations,” said Jon Ball, president of eVinci Technologies at Westinghouse. “We look forward to our partnership with CORE POWER, bringing the unique advantages of eVinci microreactors to maritime and coastal applications, potentially even paving the way for future disaster relief efforts.”

The eVinci microreactor builds on decades of Westinghouse innovation, which the company said will bring carbon-free, safe, and scalable energy wherever it is needed for a variety of applications, including providing reliable electricity and heating for remote communities, universities, mining operations, industrial centers, data centers, and defense facilities, and soon the lunar surface and beyond.

The eVinci microreactor has very few moving parts, working essentially as a battery, providing the versatility for power systems ranging from several kilowatts to 5 MW of electricity, delivered 24/7 for eight-plus years without refueling. It can also produce high temperature heat suitable for industrial applications, including alternative fuel production such as hydrogen, and has the flexibility to balance renewable output. The technology is factory-built and assembled before it is shipped in a container.