Mitsubishi Power, a subsidiary of Mitsubishi Heavy Industries Group, will supply a 180-MW class gas turbine combined-cycle (GTCC) power plant fired by blast furnace gas (BFG) to Jiangsu Shagang Group, a Chinese steelmaker. The order, which includes an M701SDAX gas turbine as a key component, was received through Mitsubishi Power’s local subsidiary.

The GTCC plant will utilize gas emitted by the blast furnace operated at a Jiangsu Shagang Group company to provide part of the power needed to run its factory. Amid today’s global initiatives to reduce environmental impact, the steel industry is facing strong pressure to reduce its carbon emissions. Because BFG-fired GTCC systems use the byproduct gases emitted by steel plants, they lighten environmental loads and contribute to efficient energy usage.

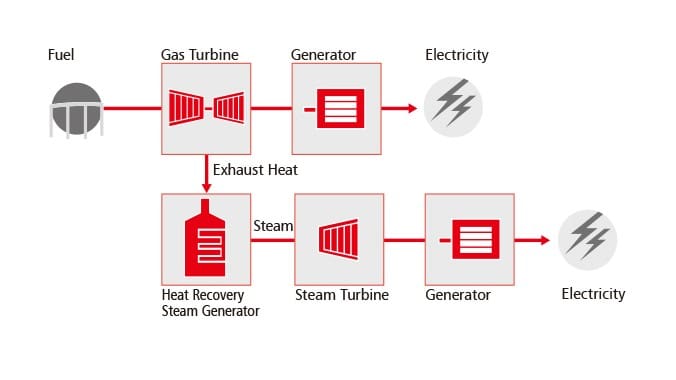

The BFG-fired GTCC power plant will be delivered to Zhangjiagang Hongchang Plate Co. Ltd. in Zhangjiagang, a county-level city under the administration of Suzhou, Jiangsu Province, situated approximately 100-km northwest of Shanghai. The facility will comprise a gas turbine, heat recovery steam generator, steam turbine, generator, gas compressor, and auxiliary equipment.

Mitsubishi Power will manufacture the M701SDAX gas turbine at its Takasago Works in Hyogo Prefecture. The steam turbine and generator will be provided by Dongfang Electric Group, a Chinese manufacturer of heavy electric machinery with which Mitsubishi Power has a cooperative relationship.

Operation of the new power plant is scheduled to commence in 2023.